Guillow's 1/16 Spirit of St. Louis

| KIT #: | 807 |

| PRICE: | $46.59 MSRP |

| DECALS: | One option |

| REVIEWER: | Paul Oberle |

| NOTES: | Balsa, tissue and plastic multimedia kit |

| INTRODUCTION |

Some time

back, in one of my rare contributions to a discussion thread at Modeling

Madness, I made note of my newly acquired balsa kit.

At that time I also remarked that the interests at MM seemed to be

in plastic model kits and not much else.

Without letting too much time go by, our Administrator rejoined that

nowhere in the site’s policies, philosophies, discussions, etc. was there a

mention that styrene was the rule, or even that it was preferred here at MM.

And, in fact, if someone wanted to make a contribution in another area

then one should do so.

Appropriately chastened, I realized that not only did I have to get on with

building this kit, but now I had motivation to provide a review. First of all, I

have to go on record as having built exactly one other balsa kit in my life.

My initial try was the Wright Flyer.

Not a terrible experience, but certainly not enough to make me a balsa

expert. And as I was about to find

out, this kit was going to be a whole lot different, especially in the amount of

wing and fuselage area needing to be covered.

At any rate, knowing that there are more than a few of you out there who

are proficient with these kits, I’ll offer this write-up as more my experience

with the

build rather than a critique of the kit.

Maybe you’ll be able to relate.

Maybe you can show me the error of my ways.

For those who have never tried a balsa kit, I hope this won’t scare you

away.

build rather than a critique of the kit.

Maybe you’ll be able to relate.

Maybe you can show me the error of my ways.

For those who have never tried a balsa kit, I hope this won’t scare you

away.

With

regard to the kit itself, I’ve always liked the

Spirit of

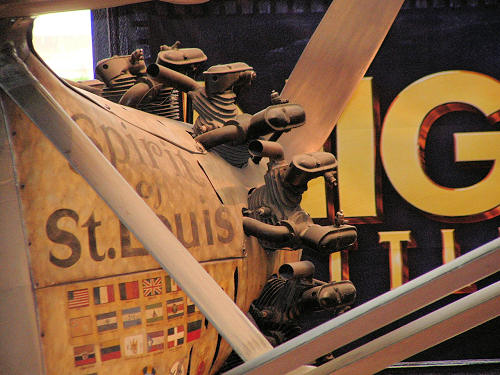

Not long

after visiting the Internet for helpful hints, I made a basic decision to build

this right out of the box. What I found on the Net left me more than a little

stunned by what some really talented people can do with this model.

Some folks had essentially thrown the kit parts away but kept the plans

and built a fresh model from scratch. Some modelers had opted for thin balsa

sheets rather than tissue for the skin.

(This technique was suggested by several here at MM.)

I found a Spirit with a

detailed interior with an instrument panel and flight controls - even a wicker

seat for Lindy to sit in. I saw a miniaturized Whirlwind engine super detailed

down to ignition wires. New props had been fashioned for some models; one was

machined from stock aluminum; another was freshly cast in resin. Another kit had

cast resin cylinders for the engine and wheel hubs drilled out and replaced with

plastic sheet. In several cases,

the plastic engine cowling from the kit had been tossed and replaced with

aluminum sheeting cut to size and then burnished for real – just a smaller

rendition. These were really some

show stopping prize winners.

It

occurred to me then that by comparison, my airplane might look very much like

Charlie Brown’s Christmas tree.

Not to

panic, however. What I do in times

like these is invoke the spirit of one o f my cinematic heroes of the distant

past, Inspector Harry Callahan. In the movie, Magnum Force, Dirty Harry

utters the unforgettable line, “A man’s got to know his limitations.”

I have adopted this philosophy as my mantra and guiding light – and not

just for building model airplanes.

f my cinematic heroes of the distant

past, Inspector Harry Callahan. In the movie, Magnum Force, Dirty Harry

utters the unforgettable line, “A man’s got to know his limitations.”

I have adopted this philosophy as my mantra and guiding light – and not

just for building model airplanes.

So then I

was resolved. I was, in fact, not

going to bite off more than I could chew with this project.

Everything I need for a decent plane is going to be right in the box.

This is going to be enough of a challenge as it is.

As one

might imagine, there is an absolute mountain of information about Lindbergh, the

airplane and the flight. Histories

abound on different websites; books are readily available (Lindbergh himself

wrote a couple accounts of the flight).

There are bios and opinion pieces everywhere regarding Lindbergh and his

politics. There are also a couple

of movies. If you’re so inclined,

you can take in Billy Wilder’s 1957 epic entitled (what else)

The Spirit of St. Louis

starring Jimmy Stewart (at age 48 playing Lindbergh at 25).

And - if

you’re as lucky as I am to live close by, you can go down to the Smithsonian in

Washington, D.C. and see the real deal hanging from the ceiling of the Air and

Space Museum. That’s pretty neat.

For a

concise history, one has to go no farther than right here at Modeling Madness.

Bill Michaels provided an excellent write-up as part of his kit preview

back in 2006 for the Revell 1/48 offering.

Here is the citation for your convenience.

http://www.modelingmadness.com/reviews/civil/previews/michaelssoslpreview.htm

For those

of you who can’t tear yourselves away, here is the brief history as it appears

on the plaque in front of the Spirit

at the Smithsonian:

For those

of you who can’t tear yourselves away, here is the brief history as it appears

on the plaque in front of the Spirit

at the Smithsonian:

Ryan NYP

Spirit of

First Nonstop Solo Transatlantic

Flight

“On May

21, 1927, Charles A. Lindbergh completed the first solo nonstop transatlantic

flight in history, flying his Ryan NYP

Spirit of St. Louis, 5,810 kilometers (3,610 miles) between Roosevelt Field

on Long Island, New York and Paris, France, in 33 hours, 30 minutes.

With this flight, Lindbergh won the $25,000 prize offered by New York

hotel owner Raymond Ortieg to the first aviator to fly an aircraft directly

across the Atlantic between New York and Paris.

When he landed at Le Bourget Field in Paris, Lindbergh became a world

hero who would remain in the public eye for decades.

The

aftermath of the flight was the “Lindbergh Boom” in aviation: aircraft industry

stocks rose in value and interest in flying skyrocketed.

Lindbergh’s subsequent U.S .and Central and South American tours in the

Spirit demonstrated the potential of

the airplane as a safe, reliable mode of transportation.”

| THE KIT |

The kit

comes in a big 20 inch box that has a surprising amount of heft to it.

That’s because there’s a lot of stuff in there.

The plane itself is big - a 34 1/2 inch wingspan - so a fair amount of

building material is supplied. Most

of your balsa needs are taken care of by individual sheets coded for a specific

part of the build (e.g. the fuselage, the wing, the rudder, etc.). The

individual pieces have been die-cut for you.

The sheets contain the larger pieces for structural members like

bulkheads and wing ribs. Also

supplied is what they call ‘spaghetti’.

Don’t think of a mound of hot pasta, but rather the pre-cooked brittle

version that comes

from the deli.

Balsa sheets have been sawn into long strips of varying dimensions (e.g.

1/16X1/8 inch, 1/16X1/16 inch). The

dimensional strips have to be cut away from the block of spaghetti as you use

them. The 1/16 pieces were used

primarily as horizontal stringers to build the front of the fuselage and for

wing spars.

from the deli.

Balsa sheets have been sawn into long strips of varying dimensions (e.g.

1/16X1/8 inch, 1/16X1/16 inch). The

dimensional strips have to be cut away from the block of spaghetti as you use

them. The 1/16 pieces were used

primarily as horizontal stringers to build the front of the fuselage and for

wing spars.

Also in

the box – tissue paper to hang skin on all the surfaces; steel wire of different

gauges for the landing gear and other structural hook-ups; vac-formed plastic

for the engine cowling, wingtips, prop and other details; a nice sheet of

decals, too. Plastic wheels are included as is a sheet of clear acetate to be

used for the windows and skylight.

Detailed plans are provided. You’ll have

two big sheets by the time you cut them into usable sizes.

In reality they’re templates that you use for constructing the main

sections of the plane.

The

Guillow’s folks have concocted this kit with the basic notion that it will fly.

The plans let you build a dihedral into the wing if you want to launch it

into the wild blue yonder. (The wing on the real

Spirit was flat.)

They supply additional materials for strengthening the frame to accept a

gas engine or tensioned for a rubber band motor.

They give you equipment to hook up hand held line controls so you fly it

from the ground. Also included is a light-weight prop. They even supply a lump

of clay that can be used to distribute weight in strategic areas for balance.

The kit is very well stocked. True, there are no duplicate plastic pieces, but there is more than sufficient balsa and tissue to accommodate a normal amount of screw-ups and do-overs. For the more egregious and/or repetitive screw-ups that require even more do-overs, you may have to resupply at your local hobby store. I know I did.

| CONSTRUCTION |

Tools and

Equipment

For

starters you must have a decent surface on which to work; a building board, if

you will. There are commercial

items available, but a cost effective and user-friendly item is foam-core board.

They come in varying thicknesses, but all you need is something that will

hold a straight pin. The plan – the template really – is tacked down flat to the

board. You’ll then need to cover it

with something akin to Saran Wrap (the filmy plastic stuff).

Glues don’t necessarily stick to Saran Wrap, so this avoids your gluing

your balsa pieces to the paper plan and ruining it.

Using the template as a guide, you pin your balsa pieces directly to the

board on top of the template, gluing pieces together as necessary as you move

along. By the way, you need lots

and lots of straight pins.

Cutting

and shaping is the name of the game.

You need the biggest multi-pack of No. 11 X-acto blades you can find.

Also necessary is a large supply of single edged razor blades.

Optional, but very handy, is a razor saw and mini miter box.

I used my pin vise to drill any number of holes.

Lots of sandpaper in a variety of grits is required.

Glue,

glue and more glue. I’m not sure if

there was any type of glue not used in this build. I used white glue, yellow

glue, fast setting CA, slow setting CA.

I used a two part epoxy, plastic tube glue and plastic liquid glue.

A glue stick also got some use.

Loads of

hand tools from my tool box were employed:

several different pliers, tack hammer, measuring tapes & rules.

I even put my bench vise to use.

I used a compass, protractor and straight edge. Scissors came in handy,

as did clothes pins to act as clamps.

Finally,

I shouldn’t omit the electric rotary tool.

That item proved invaluable in cutting wire and also for boring and

shaping some plastic pieces. I’d

still be plugging away at the workbench if I didn’t have it.

Finally,

I shouldn’t omit the electric rotary tool.

That item proved invaluable in cutting wire and also for boring and

shaping some plastic pieces. I’d

still be plugging away at the workbench if I didn’t have it.

Consider

the plans. If your only modeling

experience has been with mainstream plastic kits, you’re probably used to seeing

a set of numbered instructions that lead you through a, more or less, logical

sequence of assembly. Well, this is

a little bit different. You can

start with the wing. You can start

with the fuselage. You can start

wherever you want. The real

construction is in the plane components. In fact, actual assembly of the parts

into the final product is relegated to a tiny narrative in the plans with an

even tinier blow-up showing the assembly.

However, by the time you get there, you’ll be intimate with all the

details and know where everything goes.

Most

model kit instructions say “Please read the instructions.”

Well, here they’re not kidding.

While the plans lay out the location of each individual piece, they also

provide lots of side notes with special instructions along with blow-ups of more

complicated areas of construction.

There are little details depicted that, if you ignore them or miss them early

on, they’ll come back to bite you later.

It’s a good idea to get out your yellow highlighter or red pen and put it

to use early and often.

The Build

Each

balsa piece has to be removed carefully from its background sheet.

Just because the outline has been pre-cut, doesn’t mean you can pop these

out with your thumbs. Sometimes the

cut hasn’t gone all the way through, and other times the piece is just too thin

or delicate. You’re also going to

have to ‘dress’ each piece, removing nubs and splinters and providing sanding on

some rough edges. All in all, the

pre-cut pieces are great. I can’t

imagine the olden days when pieces had to be sawed or carved individually.

Fuselage

For no

special reason I started with the fuselage. With the initial perimeter pieces

tacked down, you have the central axis of the airplane (i.e. lengthwise through

the middle of the fuselage) outlined.

From here you build out the left side of the fuselage by adding half a

bulkhead at a time making sure it stays perpendicular to your central axis.

You then add a keel to the side to stiffen the whole section.

Upon completion, this half fuselage is removed from the building board

and construction commences on the right side.

The principal concern here is keeping your right-side bulkhead half on

the same plane as its mate on the left side.

The glue stick came in handy as a couple of 1/16 inch scraps were

temporarily glued to the left half bulkhead with one edge hanging out as a guide

and glue surface for the right side half to match up.

Early on,

I opted to build in a moveable door rather than just penning the outline of the

door onto the fuselage. The door

frame was prepared on the template using the 1/16 inch strips.

The door, however, has to be curved top to bottom to fit the rounded

contour of the fuselage. This is

accomplished by soaking the completed door frame in water.

While still wet, it is placed over some dimensional ‘risers’, the largest

of which is placed across the middle of the door.

The top and bottom of the door are then pinned down to the work board.

When the wood dries you’ll have your permanent curve to the door.

Early on,

I opted to build in a moveable door rather than just penning the outline of the

door onto the fuselage. The door

frame was prepared on the template using the 1/16 inch strips.

The door, however, has to be curved top to bottom to fit the rounded

contour of the fuselage. This is

accomplished by soaking the completed door frame in water.

While still wet, it is placed over some dimensional ‘risers’, the largest

of which is placed across the middle of the door.

The top and bottom of the door are then pinned down to the work board.

When the wood dries you’ll have your permanent curve to the door.

To shape

the fuselage, 3/8 inch stringers are attached to the bulkheads.

The fast set CA glue was most useful here.

Since the fuselage tapers from front to rear, the stringers have to bend

somewhat at each bulkhead. Starting

at the first bulkhead, the fast set glue grabbed the stringer and set fast

enough that you could move on to the second, third, etc. bulkhead, accommodating

the bends and really not slowing down.

You get to the rear of the fuselage and snip off any excess stringer. Go

back to the front and start your second stringer.

Then repeat, repeat, repeat.

Before

all the stringers are all in place, you’re going to have to address the landing

gear. Again, since the finished

model is supposed to fly….and ultimately land….the Guillow’s folks want landing

gear that can take a beating. In

lieu of stronger plywood, the kit supplies a stiff vinyl.

Here again, pieces have been already die cut for you.

And that’s a good thing since this stuff is tough to cut.

Parts to form a cradle for the 1/16 inch landing gear wire are glued to

the forward bulkhead. This is

where the two-part epoxy was recommended for a super tight bond.

The 1/16 inch wire then has to be bent

and manipulated to become the axles and the struts for the landing gear.

I have to

add a word here about bending wire.

To be good at this, it will be necessary to make a pact with Satan.

I found it that frustrating.

First of all, 1/16 inch may not sound like much, but that steel wire is a bugger

to bend. My wire bending technique

is to drive a nail into a largish piece of plywood. I use the nail as the pivot

point for the bend. With a pair of

pliers in each hand, and the wire flat on the plywood, I bend away, taking the

wire back to the template after each little tug to check if I’m getting close to

the appropriate angle. After

following that routine umpteen times and getting it where I want it, I move on

the second bend. I get the exact

mark and start a new reverse angle.

But upon checking back with the template, this new bend isn’t exactly where I

want it. What the….???

The distance between the two angles is just a little too long.

On the second attempt, well, it’s just a little too short.

And guess what? If you try

to un-bend your initial angle and move it a smidge, you’re just asking for more

trouble. The wire doesn’t un-bend

without leaving a noticeable kink.

So then, how many angles are needed in this piece of wire? Only four?

Might have just as well been forty.

In addition, it’s a hot, humid night.

I’m working on the floor of my garage.

With my head down, sweat balls are dripping onto the inside of my

glasses. I’m looking through a

goldfish bowl. I’m fairly

miserable. Finally, after

much blood, sweat and tears I get the wire bent to where I want it. I lay it on

the template for a final look and realize that one end is up in the air.

It doesn’t lay flat anymore.

Now I’ve lost the flat axis I started with.

I have to

add a word here about bending wire.

To be good at this, it will be necessary to make a pact with Satan.

I found it that frustrating.

First of all, 1/16 inch may not sound like much, but that steel wire is a bugger

to bend. My wire bending technique

is to drive a nail into a largish piece of plywood. I use the nail as the pivot

point for the bend. With a pair of

pliers in each hand, and the wire flat on the plywood, I bend away, taking the

wire back to the template after each little tug to check if I’m getting close to

the appropriate angle. After

following that routine umpteen times and getting it where I want it, I move on

the second bend. I get the exact

mark and start a new reverse angle.

But upon checking back with the template, this new bend isn’t exactly where I

want it. What the….???

The distance between the two angles is just a little too long.

On the second attempt, well, it’s just a little too short.

And guess what? If you try

to un-bend your initial angle and move it a smidge, you’re just asking for more

trouble. The wire doesn’t un-bend

without leaving a noticeable kink.

So then, how many angles are needed in this piece of wire? Only four?

Might have just as well been forty.

In addition, it’s a hot, humid night.

I’m working on the floor of my garage.

With my head down, sweat balls are dripping onto the inside of my

glasses. I’m looking through a

goldfish bowl. I’m fairly

miserable. Finally, after

much blood, sweat and tears I get the wire bent to where I want it. I lay it on

the template for a final look and realize that one end is up in the air.

It doesn’t lay flat anymore.

Now I’ve lost the flat axis I started with.

“B-R-R-I-N-N-G-G-G”, “B-R-R-I-N-N-G-G-G”

(Telephone ringing sound)

Satan:

“Hello. This is Hell.”

Paul:

“Hi, there. Is this Mr.

Satan?”

S:

“Why, yes it is.”

P:

“Hi, this is Paul.”

S:

“Good to hear from you, Paul.

Can I put you on hold for a moment?”

P:

“Sure. No problem.”

This point in the build is also where

the first of many adventures in plastic begins. I have no room to be critical,

but if there’s a red-headed stepchild in this kit, it’s the plastic.

I had never worked with vac-plastic before, but thanks to some good

advice obtained here at MM, the cutting and sanding was a breeze.

I suppose, however, that if you’ve built plastic models all your life,

you have expectations that parts will fit reasonably well; for instance, that

halves will mate up. Even when

filler putty is needed, you get pretty close to a finished surface.

Not so much here, though.

The cowling was formed by two (top and bottom) clamshell shaped pieces.

They seemed fine after cutting them from the sheet, but the plans said

that the top was to overlap the bottom by 1/16 inch.

In reality there was a 1/16 inch gap between the two halves. Also, the

two pieces were to reach horizontally from the nose to the first major bulkhead

which was to be a glue surface.

Well, they fell short there as well. Not really fatal flaws; I added

filler

pieces to make up for the gaps and to give me a place to glue the cowling down.

I then broke out the putty and started sanding.

filler

pieces to make up for the gaps and to give me a place to glue the cowling down.

I then broke out the putty and started sanding.

The cowling also provided dimples as

locators for the nine engine cylinders.

They were close, but sadly, no cigar.

I had to give myself a geometry refresher course to see if I could get

those nine cylinders to look a bit more symmetrical going around the nose.

I located new points and then bored larger holes of sufficient diameter

to accept the cylinders.

The

cylinders themselves provide another case in point.

After cutting 18 little halves from the plastic sheet, you pair them

together and come to realize that no two are alike.

They are all in varying stages of roundness.

The best one is close to being round.

The worst one looks like Aunt Dorothy sat on it.

At any rate, I did try to detail these guys a little bit by adding rocker

boxes that I shaped from balsa and exhaust and intake pipes fashioned from 14

gauge electrical wire. Crude, but

better than what I started with.

Pushrods might get added later. (Frankly, it’s more than I want to take on right

now.)

My final

rant regarding the plastic has to do with the prop.

Here again were two halves that had to be joined.

The blade on one half was ridiculously shorter than the other.

Overall there were so many gaps in the seams you had enough daylight to

read by. I actually went out and

bought a wooden prop for an RC aircraft that I thought I could sand into shape.

I realized pretty quickly that was going

to prove to be more work than I needed.

I bit the bullet and went back to the kit plastic.

Putty… sand. Putty…sand.

Repeat. Repeat.

Repeat.

Tail

Feathers

The tail

assembly was the next. These parts:

rudder, tail fin, stabilizers, elevators, weren’t too tricky; just another

exercise in templates, straight pins and glue.

The kit gives you the option of having moveable control surfaces.

Of course, you have to build them in if the plane were to be a flying

model. For the static model the

plans suggested using a marker pen to outline the rudder, elevators and

ailerons. That technique was also

recommended for the door. Well, in

for a penny, in for a pound. Since

I was in it this far, I might as well go for the moveable surfaces.

To create a hinge for the moveable pieces, the plan recommends cutting a

tiny rectangle from the clear acetate sheet supplied in the kit.

In some instances the hinge is sandwiched between two framing pieces and

glued into place. In other cases,

you have to carve out a slit to accept one edge of the hinge.

Since these moveable surfaces (e.g. rudder to tail fin) are going to be

attached to each other, you need to pay attention to alignment since a pocket

will be needed for the hinge on the corresponding piece.

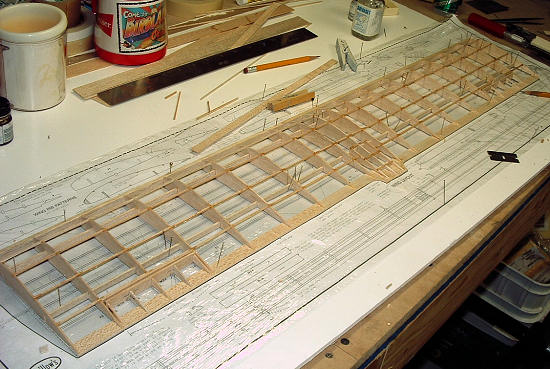

Wing

Construction of the skeleton for the wing went relatively easily. After laying

down the leading and trailing edges and two structural spars, the wing ribs were

added one by one. There is about an

acre of wing here so this takes a while.

The 1/16 inch stringers are then added horizontally across the ribs.

The problematic part of the wing construction is sanding down the leading

edge. The original dimension of

this piece of balsa is 3/16X3/8 inch.

You need to sand away probably a third of it to get the profile shaped to

where you want it. Since the whole wing is 34 inches long it is extremely

unwieldy to handle. You have to

figure out a way to hold it and sand at the same time.

My method made it look like I was playing the washboard in a jug band.

I still wound up sticking my thumb through at least five different

stringers and had to go back and splice in new pieces.

Adding the plastic wing tips was the final step.

I have to report that they were the best of all the plastic pieces.

No problems in cutting or installing.

Construction of the skeleton for the wing went relatively easily. After laying

down the leading and trailing edges and two structural spars, the wing ribs were

added one by one. There is about an

acre of wing here so this takes a while.

The 1/16 inch stringers are then added horizontally across the ribs.

The problematic part of the wing construction is sanding down the leading

edge. The original dimension of

this piece of balsa is 3/16X3/8 inch.

You need to sand away probably a third of it to get the profile shaped to

where you want it. Since the whole wing is 34 inches long it is extremely

unwieldy to handle. You have to

figure out a way to hold it and sand at the same time.

My method made it look like I was playing the washboard in a jug band.

I still wound up sticking my thumb through at least five different

stringers and had to go back and splice in new pieces.

Adding the plastic wing tips was the final step.

I have to report that they were the best of all the plastic pieces.

No problems in cutting or installing.

Paper

Hanging

After

completing all the shaping and sanding and gluing of the balsa pieces, I was

actually looking forward to hanging the tissue paper on the frame.

Little did I know that this was to be another descent into modeling hell.

The time honored substance used to attach and finish tissue is dope.

I had tried this previously on my Flyer model and didn’t have much

success. It didn’t seem to have

enough stick-um to it. As an

alternative to dope, Guillow’s and others recommend a solution of white glue

diluted with water (ratio ranging from 50-50 to 70-30).

Since this worked for me before, I followed Nancy Reagan’s advice and

just said “No” to the dope and went with the white glue. The procedure is to

apply a coat of the white glue solution on all the wood surfaces to act as a

sealant. After that dries you

lightly sand and recoat with the same solution.

While it’s still wet you can begin to hang the paper.

The instructions recommended covering a large area with only a few pieces

of tissue (e.g. two pieces only for one side of the wing).

On my first attempt at this I got very uneven adhesion.

I suspect I didn’t use enough glue in certain spots and it dried before

the paper touched down. I also

found the tissue to be rather unforgiving in trying to re-glue those areas that

weren’t tacked down. If I made a

tiny cut on top of a wing rib to inject a bit of glue, it eventually just sagged

and looked fairly pitiful. Oh well,

let’s re-do. On the next

go-round I used smaller pieces of tissue (e.g. six pieces to cover the wing this

time). I had a bit more success

doing it that way.

Once the

paper adheres, it gets a spritz of water.

Then you walk away until it dries.

As the water evaporates, the tissue contracts taking out any wrinkles

that might have been there initially.

You wind up with a taut surface stretched over the frame.

So far, so good. At

this point the surface has to be sealed to close up all those pores in the

tissue. Here again, if you’re not

using dope, the same white glue solution is used.

I used a wide brush and, applying in one direction, covered the tissue.

The whole thing then needs time to dry.

These

intervals set you free to work on some other part of the plane or just call it a

night and go to bed. Invariably,

when I chose the latter and came back for a look the next morning, I felt like

Forrest Gump with his box of chocolates.

I never knew what I was gonna get. I had a heck of a time with the curved

edges, especially the outer edges on the stabilizer, elevators and rudder.

I couldn’t avoid the paper puckering and leaving unsightly wrinkles.

Also on these particular parts , the framing pieces were fairly wide.

I must have applied too much solution and saturated the tissue to where

it was weighed down and stuck flat to those surfaces.

It didn’t leave me the crisp trailing edge I was looking for.

Oh well, let’s re-do.

, the framing pieces were fairly wide.

I must have applied too much solution and saturated the tissue to where

it was weighed down and stuck flat to those surfaces.

It didn’t leave me the crisp trailing edge I was looking for.

Oh well, let’s re-do.

Eventually I took the approach of gluing the top surfaces (leading edge and ribs) but as I got to the trailing edge I would apply glue to the opposite side of the frame only, pulling the paper taut and wrapping it around. That seemed to get my puckers removed and gave me a much neater edge. I wish I could say I found a technique to solve all my problems, but there seemed to be many, many gremlins at work.

| COLORS & MARKINGS |

Painting

Painting

the airplane wasn’t a step in and of itself.

It was more a continuation of finishing the tissue.

Given the large surface areas, I decided to go the spray can route.

I wound up with a Krylon aluminum that I selected only because I liked

the color…. metallic, but not too shiny.

After making a few passes and getting what I thought was good coverage, I

realized it wasn’t. When I held it

up to the ceiling light, well, …. I could see the ceiling light.

So what’s the deal here?

Does it need more white glue to seal the tissue?

What will the glue do on top of the paint? Let’s give that a try.

That doesn’t work. Let’s

re-do.

What

ensued were very many re-dos. I would cut out the bad section with the X-acto

blade and then scrape and sand the residual paper and glue off the spars and

ribs. Then I’d measure and cut a

piece of tissue to fit, and patch on this new replacement piece.

I’d apply my white glue solution and let it dry.

I’d apply paint and let it dry.

I just could not, however, beat the odds of having another sag or wrinkle

appear. I wound up having to

replace a bit of the skin on the fuselage, but compared to the wing, that was a

walk in the park. I replaced

probably three quarters of the tissue on both sides of the wing at least once;

some sections twice.

One

evening I found myself examining a section of wing I didn’t particularly like.

I knew I had replaced it at least once before. As I picked up the X-acto

blade to start another re-do, I felt a tap on my shoulder.

Thankfully, it wasn’t Satan.

It was, however, Inspector Callahan.

Harry noted that this was all going nowhere fast and suggested that

perhaps I had reached the limit of my limitations.

When he asked, “Do you feel lucky?” I felt that I should take his message

to heart. Let’s wrap this thing up.

From the

beginning I had wanted to do something to set the cowling off since the

burnished whorls on the real thing give it such a distinctive look.

But since I wasn’t going the route of real aluminum sheeting, what’s out

there for alternatives? I

considered a free-hand paint job, but felt pretty quickly that would prove

disastrous. One day, while cruising

the aisles in the paint department at Home Depot, I came upon a product called

‘Hammered’, offered in a spray by the Rust-Oleum people.

(‘Hammered’…..what a great name!

I was so much looking forward to quitting for the night and getting

myself just that way.) The spray is for outdoor use for porch railings, lamp

posts and such and leaves a textured finish that looks……well ……hammered.

I thought that this could be the answer.

I masked off the back of the fuselage and gave the cowling a couple of

coats of ‘Hammered’. It did leave a

texture, but nothing overly dramatic. It was enough to differentiate it from the

rest of the skin, plus it was a shade different color.

I then added some Formaline art tape to the cowling to serve as the panel

lines. I was as happy as a clam.

From the

beginning I had wanted to do something to set the cowling off since the

burnished whorls on the real thing give it such a distinctive look.

But since I wasn’t going the route of real aluminum sheeting, what’s out

there for alternatives? I

considered a free-hand paint job, but felt pretty quickly that would prove

disastrous. One day, while cruising

the aisles in the paint department at Home Depot, I came upon a product called

‘Hammered’, offered in a spray by the Rust-Oleum people.

(‘Hammered’…..what a great name!

I was so much looking forward to quitting for the night and getting

myself just that way.) The spray is for outdoor use for porch railings, lamp

posts and such and leaves a textured finish that looks……well ……hammered.

I thought that this could be the answer.

I masked off the back of the fuselage and gave the cowling a couple of

coats of ‘Hammered’. It did leave a

texture, but nothing overly dramatic. It was enough to differentiate it from the

rest of the skin, plus it was a shade different color.

I then added some Formaline art tape to the cowling to serve as the panel

lines. I was as happy as a clam.

The tires

were painted Model Master black; the prop was done in Model Master steel.

The engine cylinders were done in Testor’s (the little square bottle)

flat black; touchups everywhere were done in Testor’s aluminum.

Taking a

tip from the pages of Modeling Madness I gave the entire plane a coat of

Future floor wax. I didn’t know

what to expect, but I knew I needed a surface for the decals.

No harm, no foul. The Future

went on fine. Nothing eroded or

dissolved.

The decals are a nice asset to this kit. Actually, there aren’t that many, but in this scale they cover a lot of area. The registration numbers are so large that I didn’t debate for a second to cut each numeral out separately from the backing. The cowling and rudder decals went on without a hitch.

| FINAL CONSTRUCTION |

The last

real construction to do on the kit was to prepare the wing struts.

Again for strength, the kit opts for the 1/16 inch vinyl which is

sandwiched between two layers of balsa.

Sanding renews in earnest as this boxy section needs to be taken down to

a streamlined profile. Here also, I

had to revisit my favorite pastime of wire bending.

A thinner gauge wire is used here so cursing can be kept to a minimum.

A U-shaped affair is fashioned to form what is essentially a tab that is

attached to either end of the strut.

The tabs on one end are inserted into pockets under the wing; the tabs on

the other end go into pockets in the fuselage and landing gear.

here so cursing can be kept to a minimum.

A U-shaped affair is fashioned to form what is essentially a tab that is

attached to either end of the strut.

The tabs on one end are inserted into pockets under the wing; the tabs on

the other end go into pockets in the fuselage and landing gear.

With the

stabilizer on and the rudder affixed, the wing then gets glued down.

The struts are inserted. The

wheels go on their wire axles and……Voila!......it looks very much like an

airplane.

About

this time I was thinking how nice it would be to go to a plastic sprue and nip

off some tiny, highly detailed piece and just glue it on the model to finish it

off. But we can’t get all

delusional here. This is a balsa

kit. If you want detail, you build

it. Individual items yet to be

added included the pitot tube, the carburetor, aileron & elevator horns, gas

tank vents and that curious wind compass generator that goes atop the fuselage.

The pitot

tube was fashioned from a length of 1/16 inch balsa sanded down to a thin reed.

The lower portion of the tube with the curved section was accomplished

through soaking the wood and bending it before it dried.

I cut a small section out of the arc and glued it to the main piece.

The carburetor is a conglomeration of balsa discs and square stock all

glued together with liberal amounts of putty applied.

The control surface horns were shaped from scrap pieces and drilled to

accept the control cable. The tear drop gas vents were shaped from balsa scraps

with a piece of wire added for the actual vent tube. The wind generator was

probably the most challenging of the details.

To form the cups I used a hardwood dowel that came with the kit.

I tapered one end of the dowel and blunted it a bit by sanding a softer

bowl shape to it. When I was

reasonably happy I took the dowel to the miter box and sawed off my rounded cup.

Then I did that three more times.

I drilled a hole in the side of each little cup to accept a 0.03 inch

wire and attached it with CA. Two

cups were attached to either end of a 5/8 inch length of wire.

I made two of these and crossed them at a right angle.

I sandwiched the junction between some scrap balsa and sanded it into a

hub. I then attached that to a

pedestal for positioning on top of the plane.

Lest I forget, my last detail was to add a little piece of balsa and

cardboard to the side of the fuselage to represent the periscope.

You know

what? We’re there.

| CONCLUSIONS |

Not

everyone’s cup of tea, to be sure, but maybe every modeler should have at least

one balsa kit in his or her portfolio.

It may be a throwback, but there is still plenty of interest in building

these kits and not just from the RC crowd.

I think they offer loads of challenges, but in the hands of a competent

and patient modeler (not using me as an example) some really great results can

be  achieved. Comparison to an

injection molded plastic kit is probably inevitable, but I really think that

should be avoided. A balsa kit just

happens to be a different species altogether.

To be certain, it is not a weekend project.

And in reality, you don’t want to rush it. Half the fun (really) is in

getting there. I actually did use

it as my chance to unwind in the evenings by retiring to the garage workbench

with my favorite CD and favorite beverage(s).

I got a nice sense of satisfaction watching this thing progress over the

months.

achieved. Comparison to an

injection molded plastic kit is probably inevitable, but I really think that

should be avoided. A balsa kit just

happens to be a different species altogether.

To be certain, it is not a weekend project.

And in reality, you don’t want to rush it. Half the fun (really) is in

getting there. I actually did use

it as my chance to unwind in the evenings by retiring to the garage workbench

with my favorite CD and favorite beverage(s).

I got a nice sense of satisfaction watching this thing progress over the

months.

As with

anything, practice makes perfect. I

certainly know the areas where I need to improve.

I also need to ask myself about future modeling initiatives.

Do I want to invest the time and effort into new and different skills

like casting resin parts or turning pieces on a mini-lathe?

Hmmmm…….food for thought.

We’ll have to see.

| REFERENCES |

Berg, A.

Scott, Lindbergh, (New York: G.P.

Putnam’s Sons, 1998)*

Charles

Lindbergh, an American Aviator

http://charleslindbergh.com

Guillow’s

Model Builder Forum

http://balsamodels.com

Lederer,

Charles, The Spirit of St. Louis,

motion picture, directed by Billy Wilder, filmed at Santa Maria Public Airport,

Santa Maria, California, produced by Leland Heyward, 1957

Smithsonian National Air and Space Museum on the National Mall, Washington, D.C.

Virtual

Aerodrome

http://www.virtualaerodrome.com

Wikipedia

http://en.wikipedia.org/wiki/Spirit_of_St._Louis

*(If you

have even a passing interest in Lindbergh, Berg’s book is a must-read.

Mr. Berg won the Pulitzer for Biography or Autobiography for this effort.

Since it was published in 1998, the book is missing the later revelations

about Lindbergh’s additional secret families in Europe, but that’s hardly a

concern. Just a matter of time

marching on. I heartily recommend

the book.)

December 2009

Copyright ModelingMadness.com. All rights reserved. No reproduction without express permission.

If you would like your product reviewed fairly and quickly, please contact the editor or see other details in the Note to Contributors.