|

KIT: |

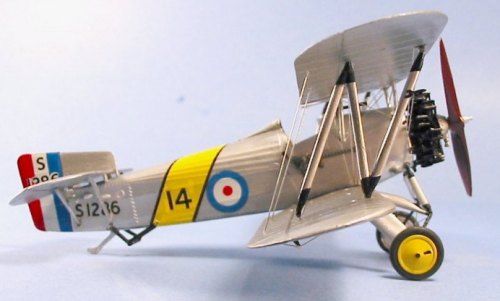

Lindberg/Inpact 1/48 Fairey Flycatcher |

|

KIT # |

? |

|

PRICE: |

Can be found for as little as $5.00 |

|

DECALS: |

one aircraft |

|

REVIEWER: |

|

|

NOTES: |

|

HISTORY |

The Fairey Flycatcher holds the honor of being the first designed-for-the purpose single-seat carrier-borne fighter to be designed and enter production. It served the Fleet Air Arm from 1923-1935, and was remembered with affection by the pilots who flew it. One, Air Commodore G.J. Christopher Paul, who was later Manager of "Air Pictorial" following retirement from active service, wrote of the Flycatcher, "It was a small and very responsive aeroplane, in which the pilot seemed only to have to think a maneuver for the Flycatcher to follow his thoughts."

By 1922, the British armed forces had been severely reduced in the aftermath of the First World War. Since 1919, British naval air strength amounted to one spotter-reconnaissance squadron, half a torpedo squadron, one fighter flight, one seaplane flight, and one flying boat flight. Between 1919-22, HMS "Argus" was the only carrier in commission. The aircraft were the Sopwith Cuckoo, the Parnall Panther, the Westland Walrus and the Nieuport Nightjar - all aircraft whose designs had originated during the war. In fact, Sopwith Camels were flown from "Argus" as late as 1920.

The RAF had been

created by the amalgamation of the Royal Flying Corps and the Royal Naval Air

Service in 1918; consequently, the Royal Navy did not have its own air force,

and flying personnel were from the RAF. The Admiralty might suggest ideas for

aircraft specifications, but the design and production of naval aircraft were

the responsibility of the Air Ministry. This was unfortunate, since it would

result in British naval aircraft always being somewhat obsolete and

second-rate, carrier-borne modifications of land-based designs that were not

conceived with the problems of carrier operation in mind. The worst example

of this would be the Sea Spitfire, which was so manifestly wrong for operation

from an aircraft carrier on any grounds other than force majeure that

five times as many would be lost to carrier operation accidents as to actual

operations.

The RAF had been

created by the amalgamation of the Royal Flying Corps and the Royal Naval Air

Service in 1918; consequently, the Royal Navy did not have its own air force,

and flying personnel were from the RAF. The Admiralty might suggest ideas for

aircraft specifications, but the design and production of naval aircraft were

the responsibility of the Air Ministry. This was unfortunate, since it would

result in British naval aircraft always being somewhat obsolete and

second-rate, carrier-borne modifications of land-based designs that were not

conceived with the problems of carrier operation in mind. The worst example

of this would be the Sea Spitfire, which was so manifestly wrong for operation

from an aircraft carrier on any grounds other than force majeure that

five times as many would be lost to carrier operation accidents as to actual

operations.

In 1922, the Air Ministry was prevailed upon to issue Specification 6/22, calling for a single seat fighter that would be capable of operating from carriers, on floats, or as an amphibian, to be powered by either the Bristol Jupiter or Armstrong-Siddeley Jaguar radial engines. Fairey Aircraft presented the Flycatcher in response. The other competitor was the Parnall Plover, which had a comparable performance but - due to the fact it was of all-wooden airframe construction - did not have the rugged strength of the Flycatcher, which was of mixed wood and metal airframe construction, with wooden wings and a wood-and-metal fuselage frame.

The prototype Flycatcher, powered by a 400 h.p. Jaguar radial, was first flown in mid-1922 by Lt. Col. Vincent Nicholl. Having completed service trials at Martlesham Heath, it went aboard "Argus" for deck-handling trials. At this time, it was equipped with steel jaws on the spreader bar to engage the fore-and-aft arrester wires then in use. Flycatchers would use this system until it was abandoned in 1926, after which they would not use any arresting device. By the time tranverse wires were introduced, the Flycatcher had been supplanted by the Hawker Nimrod.

For its time, the

Flycatcher exhibited excellent performance, though its maximum speed of 133

m.p.h. at 5,000 ft. was not substantially more than that of the fighters of

the last years of World War I. The airplane had outstanding aerobatics and

ease of handling. Its wingspan of 29 feet enabled it to be raised and lowered

on the deck elevator without need of wing folding. As with other Fairey

aircraft, it used camber-changing wings in which flaps ran the span of the

upper and lower wings - with the outer sections doubling as ailerons - which

steepened the glide path and shortened both landing and take-off runs. In

tests at Martlesham Heath, with no wind and a zero flap setting, the unstick

distance was 363 feet; with a flap setting of 8 degrees, this was reduced to

199 feet! With 8 degrees of flaps, landing speed was 47 m.p.h. Stability was

so good in a dive that the airplane could be dived vertically at terminal

velocity with no danger of overstressing it on pullout. Flycatchers wowed the

audience at the Hendon Displays of 1928 and 1929, in which 3 Flycatchers

attacked the same target simultaneously, diving from 2,000 feet from three

different directions.

For its time, the

Flycatcher exhibited excellent performance, though its maximum speed of 133

m.p.h. at 5,000 ft. was not substantially more than that of the fighters of

the last years of World War I. The airplane had outstanding aerobatics and

ease of handling. Its wingspan of 29 feet enabled it to be raised and lowered

on the deck elevator without need of wing folding. As with other Fairey

aircraft, it used camber-changing wings in which flaps ran the span of the

upper and lower wings - with the outer sections doubling as ailerons - which

steepened the glide path and shortened both landing and take-off runs. In

tests at Martlesham Heath, with no wind and a zero flap setting, the unstick

distance was 363 feet; with a flap setting of 8 degrees, this was reduced to

199 feet! With 8 degrees of flaps, landing speed was 47 m.p.h. Stability was

so good in a dive that the airplane could be dived vertically at terminal

velocity with no danger of overstressing it on pullout. Flycatchers wowed the

audience at the Hendon Displays of 1928 and 1929, in which 3 Flycatchers

attacked the same target simultaneously, diving from 2,000 feet from three

different directions.

Together with the Fairey IIIF, the Flycatcher served in every active aircraft carrier between 1923-35, with the Home Fleet, the Mediterranean Fleet and the China Station. Floatplane Flycatchers were used on the China Station and the East Indies Squadron until 1934, and were very active against Chinese pirates raiding coastal shipping near Hong Kong. A Flycatcher made the first-ever night landing aboard a carrier, flying from Hal Far, Malta, to H.M.S. "Courageous" on November 26, 1929.

In 1929, Flying Officer P.D. Cracroft, while flying with 405 Flight aboard H.M.S. Glorious in 1931, observed from the air a division of destroyers operating in low sea fog that were headed straight toward another formation to the other side of the fog bank. Since he did not have a radio to warn anyone of the danger, he deliberately ditched his aircraft alongside the flotilla to draw their attention to the danger ahead.

193 Flycatchers were eventually produced, in production batches ordered in August 1924 and 1925, and March 1930. The Flycatcher served only with the RAF. Though no original aircraft survive, a full-scale replica was created during the 1980s and flown successfully.

|

THE KIT |

The Flycatcher was

originally produced by the British model company, Inpact, and appeared in the

early 1960s, along with the Gloster Gladiator I, the Hawker Fury I, and the

Bristol Bulldog. Each of these kits are still remarkably good nearly 40 years

later, with good external detail; in fact, modern model companies producing

models of fabric-covered airplanes could profitably take a look at the

production design of each of these kits, since they create a "fabric-covered

look" that  avoids the completely-incorrect "hills-and-valleys look" so many

seem to think is what a fabric airplane looks like. Of these four kits, only

the Fury and the Gladiator have seen later competitors created by other

companies; the Inpact Fury is still superior to the later Airfix kit, while

the Gladiator is not so out-performed by the new Roden kit that a modeler

willing to expend a bit of effort detailing the cockpit will not end up with a

nice-looking model.

avoids the completely-incorrect "hills-and-valleys look" so many

seem to think is what a fabric airplane looks like. Of these four kits, only

the Fury and the Gladiator have seen later competitors created by other

companies; the Inpact Fury is still superior to the later Airfix kit, while

the Gladiator is not so out-performed by the new Roden kit that a modeler

willing to expend a bit of effort detailing the cockpit will not end up with a

nice-looking model.

The molds of all of these kits were sold around after the demise of Inpact in the later 1960s, and they have appeared in release (in order) by Lifelike, Pyro,and Lindberg. The molds created by Inpact are quite good, because I have compared a 1965 Inpact kit with a 1995 Lindberg kit, and there is not the amount of wear one might expect.

If you can, look for the Lifelike issue, since the kit decals from this company are the best; the original Inpact decals - while useable - are thick and frequently too dark in shade, while those from Pyro (who picked them up from Lifelines) are shoddy copies of the Lifelike set, with the Lindberg decals being the worst because they frequently are in World War II insignia colors, rather than the correct lighter and brighter interwar colors.

|

CONSTRUCTION |

The first thing to do with the kit is clean off mold lines and "flash" where it appears. With the fuselage halves, it is profitable to take the time to cut off the locating pints, and carefully scrape down the areas that will be glued together to get good 90-degree angles on the part, so that it fits as good as a "Tamigawa" - this will make cleaning the seam in the rear half of the fuselage where there is fabric-covered stringer detail much easier with less later loss of detail.

I used the Pilot

Press cutaway drawing of the Flycatcher in an old issue of "Air Enthusiast

Quarterly" to detail the open cockpit, using some Evergreen Rod for the

visible airframe, and scratchbuilding a seat from Evergreen sheet. I

used some Evergreen .010x.020 strip to create the former ribs in the fuselage.

When this was done, I painted the interior of the fabric-covered area dull

red, and the metal interior of the forward fuselage in light

grey, with all the

fuselage frames and stringers in gloss black. I made a Sutton harness

for the seat from lead foil.

grey, with all the

fuselage frames and stringers in gloss black. I made a Sutton harness

for the seat from lead foil.

Next was attaching the lower wing to the fuselage. The designers got this wrong, in that it would appear to be a one-piece wing attached to the lower fuselage. In actuality, the Flycatcher's lower wings were attached to the fuselage in the manner of most biplanes. What this required was a good amount of putty on the lower fuselage around the joint of the wing, to be sanded out smooth. I then used my razor saw and X-acto knife to simulate the attachment of wing to fuselage. After I sanded this as smooth as possible, along with the attachment area of the cabane struts to the fuselage and the forward fuselage centerline, I polished the forward fuselage with Tamiya polishing compound, inasmuch as this area was not only going to be painted natural metal, but would be polished out as well.

Having cut the elevators and re-attached them, I attached the horizontal stabilizer and the rudder to the fuselage and set all this aside to set up. I then assembled the three-part upper wing, filled in the area around the attachment tabs with cyanoacrylate glue and smoothed that joint over.

The engine is quite good, but it lacks the individual exhaust stacks for the engine that most Flycatchers had. I made these with some Evergreen rod, drilling out each attachment on the cylinders and gluing them in place. Since each exhaust is angled slightly different from the others - from horizontal on the top to vertical on the bottom, this was in fact the most difficult part of construction. When the engine was complete and set up, I painted it Semi-Gloss Black, as were most British engines of the period, with the crankcase cover left in Steel.

|

CAMOUFLAGE & MARKINGS |

The entire model was

painted with Floquil Old Silver. When this had dried sufficiently to still be

a bit "sticky", I applied SnJ polishing powder over the forward fuselage, all

the struts and the landing gear, applying it and polishing it out with

Q-tips. This way, once polished out, the model could be left overnight to dry

completely, with the result that the powder would adhere to the painted

surface and not require any sealer. The black areas of the N-struts and the

landing gear were hand-painted with Tamiya Semi-Gloss Black, while the prop

was airbrushed with Gunze-Sangyo "Mahogany."

The entire model was

painted with Floquil Old Silver. When this had dried sufficiently to still be

a bit "sticky", I applied SnJ polishing powder over the forward fuselage, all

the struts and the landing gear, applying it and polishing it out with

Q-tips. This way, once polished out, the model could be left overnight to dry

completely, with the result that the powder would adhere to the painted

surface and not require any sealer. The black areas of the N-struts and the

landing gear were hand-painted with Tamiya Semi-Gloss Black, while the prop

was airbrushed with Gunze-Sangyo "Mahogany."

Once all was dry, the decals were applied. These went down easily under a coat of Micro-Sol, and when dry the model was washed, and a very light coat of Testor's Sealer applied to the decals for protection.

|

FINAL CONSTRUCTION |

I attached the brace

struts for the horizontal stabilizer, the lower fuselage "grab bar" and the

tail skid, then attached the upper wing to the cabane struts with

cyanoacrylate glue, after which I positioned the N-struts and glued them in

position with Ambroid Pro-Weld. I assembled the landing gear and attached it

without problem, and then finished off with the engine and prop.

I attached the brace

struts for the horizontal stabilizer, the lower fuselage "grab bar" and the

tail skid, then attached the upper wing to the cabane struts with

cyanoacrylate glue, after which I positioned the N-struts and glued them in

position with Ambroid Pro-Weld. I assembled the landing gear and attached it

without problem, and then finished off with the engine and prop.

Rigging was done with .008 steel wire, attached with white glue. The model was originally designed so that a modeler could run thread around to rig it, and the guide holes were very useful attachment points for the wire.

|

CONCLUSIONS |

The Firefly has a very different "look" than most airplanes, with its apparently "cocked-up" rear fuselage and complicated landing gear. In that, it is "very British," but I happen to like that funky Brit look to an airplane. Luckily I have the complete line of these Inpact kits now, so the model already looks good sitting next to the Fury, and will look even better sitting there with the Bulldog soon.

March 2003

Kit courtesy of my wallet.

If you would like your product reviewed fairly and quickly by a site that has nearly 200,000 visitors a month, please contact me or see other details in the Note to Contributors.

Back to the Reviews Index Page