Airfix/Revell 1/72 York C.1

| KIT #: | 195 (CMR set) |

| PRICE: | £69.98 for conversion and kit |

| DECALS: | Ten options |

| REVIEWER: | Frank Reynolds |

| NOTES: | Resin conversion set |

| HISTORY |

During World War 2 the British aircraft industry focussed its attentions

and resources on offensive warplanes and relied upon the USA to produce

transport aircraft. One significant exception is the Avro York, which was a

simple and logical adaptation of the Lancaster bomber into a passenger and

freight aircraft. The idea for a York was mooted early in the Lancaster

programme as a private venture project and once the drawings were issued for

production, in February 1942, the first prototype flew a remarkably short five

months later, on 5 July 1942.

The

concept was logical and simple, a box section slab sided fuselage was married to

the standard Lancaster wing and tail structures. The high set wing permitted a

low slung fuselage profile with easy loading into a wide freight door on the

port side. Flight testing of the prototype revealed some directional instability

that was cured by adding a distinctive central fin to the tailplane. The York

was designed to function as a VIP aircraft, freighter, or combi

passenger/freighter. The heavy lift and long range capabilities of the

Lancaster, combined with a fuselage of much greater volume, yielded an aircraft

with a potential range of 3,000 miles and could accommodate 25-30 passengers or

8,000lbs of freight.

The

concept was logical and simple, a box section slab sided fuselage was married to

the standard Lancaster wing and tail structures. The high set wing permitted a

low slung fuselage profile with easy loading into a wide freight door on the

port side. Flight testing of the prototype revealed some directional instability

that was cured by adding a distinctive central fin to the tailplane. The York

was designed to function as a VIP aircraft, freighter, or combi

passenger/freighter. The heavy lift and long range capabilities of the

Lancaster, combined with a fuselage of much greater volume, yielded an aircraft

with a potential range of 3,000 miles and could accommodate 25-30 passengers or

8,000lbs of freight.

Production was slow, because of priority production for Lancasters and

only four prototypes and three production aircraft had appeared by the end of

1943. Regular production began in 1944, at an initial planned rate of three

aircraft per month, against an order of 208 for the RAF.

The York was intended as a long range transport, ideal for the support

of operations throughout an Empire that, although shrinking, still encompassed

outposts through the Mediterranean, into the Middle East, Africa and the Far

East. In the early post war years it was also eagerly accepted by airlines

within the British sphere of influence to help deal with an increasing demand

for long range transport. 25 were built for British Overseas Airways

Corporation, 12 for British South American Airways, three for Skyways of London,

five for Flota Aerea Mercante of Argentina.

The York earned its place in history during the Berlin Airlift of 1948.

Although the type had been designed for routes having

long stage lengths, it was pressed into service on high intensity short hops

from West Germany into the isolated city of Berlin, following a Soviet blockade.

36 RAF Yorks and four from the civil airline Skyways of London conducted some

13,180 sorties over the period June 1948 to May 1949. Taking off and landing at

maximum weight, often carrying bulk loads such as coal or flour, it was a

punishing schedule. Some aircraft were rotated back to England every 150 flying

hours for overhaul and a change of engines such was the intensity of the

operation.

The York began to fade from RAF service in the mid 1950s and many of the

airframes, like so many aircraft of the period, found new homes with smaller

independent airlines, the last being withdrawn from service in 1964

| THE KIT |

CMR’s

package is a “resin conversion” by definition, but the sheer scale of what is

provided goes way beyond the normal expectation. Packed in a stout white box is

a full kit for everything that is required to build the fuselage and tail

feathers of a York, the builder just needs to add the

wing, engine

and undercarriage assemblies from a mainstream injection moulded Lancaster of

their choice, from Airfix,

Hasegawa or Revell. The package is expertly designed so

that no major hacking or filling of parts is required.

CMR’s

package is a “resin conversion” by definition, but the sheer scale of what is

provided goes way beyond the normal expectation. Packed in a stout white box is

a full kit for everything that is required to build the fuselage and tail

feathers of a York, the builder just needs to add the

wing, engine

and undercarriage assemblies from a mainstream injection moulded Lancaster of

their choice, from Airfix,

Hasegawa or Revell. The package is expertly designed so

that no major hacking or filling of parts is required.

There are over 80 parts in the box, the resin carefully protected in

sealed bags; so carefully in fact that some of the bags are bagged! These guys

at CMR certainly go the extra mile to ensure that the parts arrive safely.

Nothing was broken, even though some of the resin castings are very delicate.

Dominating the contents are two beautifully cast full length fuselage

halves in a medium grey, dense, smooth resin. The fuselage components are

commendably thin with reasonable lightly engraved panel lines. They are so close

to plastic injection moulded parts that this kit seems to leap out of the box

calling out to be built.

The tail assembly is provided in resin, comprising the horizontal

surfaces and elevators and a choice of fins with rounded or extended trim tabs.

Paddle blade propellers, spinners and unshrouded exhaust pipes are provided. The

main wheels are the late type with treaded tyres and flats moulded on. There is

a well detailed flight deck and crew area in the nose, with commendably thin

tables for the navigator and flight engineer and appropriate bulkheads and

flooring for the crew compartments. Clear resin parts are included for the 38

fuselage windows and the astrodome. The rear fuselage is completely empty, but

this is not really a problem since little is likely to be seen through the small

circular windows. A separate freight door is provided for those who might wish

to open up the fuselage side and scratch build an interior.

The main flight deck transparency is in clear vacuform, with a spare

provided. A coloured etch fret, by Eduard, provides instrument panels for the

pilots and flight engineer and a set of canopy masks, again by Eduard, for the

flight deck glazing.

The decal sheet provides a choice of ten aircraft all from the Berlin

Airlift, all finished in silver with C1 type post war RAF roundels that are

printed in the correct shade of post war Blue. There is little difference be tween

the schemes offered beyond different fuselage codes and under wing serial

numbers. The decals originate from Tally Ho and are neatly done, in good

register.

tween

the schemes offered beyond different fuselage codes and under wing serial

numbers. The decals originate from Tally Ho and are neatly done, in good

register.

Instructions consist of eight loose leaf A4 sheets, of which four pages

are exploded view sketches, four pages give a brief history and

including 43 black and white photos showing useful

interior shots and close ups. Finally there are three pages of drawings showing

colour information and decal positions.

So confronted with a cram full box of resin parts, a comprehensive

collection of mixed media accessories and a choice of ten finishes, next is the

planning stage, for there are no instructions in the conventional sense.

Checking those references is the watchword here; not the easiest

approach, since the York is not a particularly well documented type, but it

seems that late versions had paddle blade propellers and the larger type

rudders. Yet there is enough in-box information included to build a Berlin

Airlift York with reasonable confidence.

I elected to build the fuselage and tail as a separate unit, then add

the wings from the donor kit, my choice being Revell’s Lancaster. It happened to

be the Dambuster version, but this is irrelevant since the wings are common to

each Revell boxing. The Revell kit needs a correction to the wing dihedral but I

chose it partly on the grounds of cost, since it is substantially cheaper than

the Airfix or Hasegawa competition, at least in my home market in the UK. Mine

was even cheaper than usual since it picked it up at a bargain £14-99 at the

IPMS UK Scale Model World 2013 extravaganza at Telford.

| CONSTRUCTION |

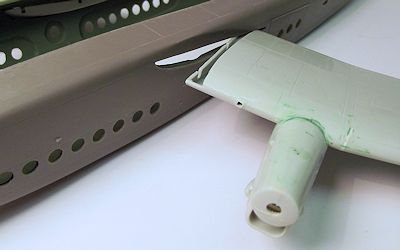

This begins with a clean up of the resin parts, but by the usual

standards of this medium relatively little is required. The moulding blocks are

joined to the main components with thin and well defined gates that are easily

dealt with using a fine razor saw. Very slight flash was present around the

window openings and the very delicate cockpit interior parts, but this was

easily stroked away with a fresh scalpel blade. The joining faces of the

substantial fuselage halves received extra attention from sanding sticks to

ensure a strong joint. The parts were then washed in warm water to which a few

drops of wash up liquid were added and then left overnight to dry. At this stage

I tried some experimental fuselage windows from blobs of Micro Kristal Kleer,

guided into a couple of the circular windows with the tip of a wooden cocktail

stick. Left to dry overnight, I

found them

to give a satisfactory result, so these temporary glazings were cut out with a

scalpel blade and discarded. I decided not to use the clear resin windows for

any of the circular openings – glazing could now be added after painting using

this Kristal Kleer method, and avoid having to mask multiple windows during

painting.

found them

to give a satisfactory result, so these temporary glazings were cut out with a

scalpel blade and discarded. I decided not to use the clear resin windows for

any of the circular openings – glazing could now be added after painting using

this Kristal Kleer method, and avoid having to mask multiple windows during

painting.

A single bulkhead divides the flight deck from the main cabin. Two

pilots seats and control pedestals are fixed in the front cockpit under the

large canopy and an overhead throttle box is provided. To the rear is a central

aisle with the engineer and navigator positions either side. The seats are well

detailed and suitable black boxes and tables furnish the rear crew positions.

The parts were assembled with thin super glue.

The flight deck area was painted black overall with seat cushions picked

out in medium green. The main fuselage interior was sprayed in Tamiya XF-71

cockpit green. Etch metal instrument panels were added to the main panel and the

two rear crew positions. I decided that there would probably have been a curtain

to divide the flight deck from the main cabin so I fixed a piece of scrap

plastic over the opening in the bulkhead, concealing the empty rear fuselage.

I superglued small plastic card tabs around the joining edges of the

fuselage halves to aid line up during assembly.

The two halves were taped together first and spot fixed

with dabs of thin superglue every 25mm or so along the joint. Once dry, the tape

was removed and medium superglue spread into the whole length of the joint. This

was left overnight to dry and ensure that all fumes evaporated. Mould shrinkage

left a clearly defined shallow groove along the length of the joint, so this was

smoothed over and filled with two-part epoxy putty. I fired over a quick

overspray of auto primer from a rattle can and rubbed it away with a fine

sanding stick. This reveals any small dings or scratches that require further

filler, using standard Green Putty.

I do

not like vacuform transparencies; I am nervous when cutting them out, fretful

when trimming them to shape and was uncertain which type of glue I should use to

fix vacuform to resin. CMR helpfully provide two transparencies in case of

accidents, both of which I messed up, but a humble e-mail to CMR brought swift

replacements and eventually I ended up with one that fitted snugly into the

cockpit area. The glazing was fixed into the nose cut out with Humbrol Clear

Fix.

I do

not like vacuform transparencies; I am nervous when cutting them out, fretful

when trimming them to shape and was uncertain which type of glue I should use to

fix vacuform to resin. CMR helpfully provide two transparencies in case of

accidents, both of which I messed up, but a humble e-mail to CMR brought swift

replacements and eventually I ended up with one that fitted snugly into the

cockpit area. The glazing was fixed into the nose cut out with Humbrol Clear

Fix.

Attention now turned to the wings. Critical to this project is the need

to provide a strong and effective joint between the plastic wing assembly and

the resin fuselage structure. CMR have come up with a brilliant and effective

solution. A slot is cast into the fuselage halves corresponding to the wing root

of just the lower half of the plastic wing and I found that the Revell component

fitted snugly. Since the York has a wider fuselage than the donor Lancaster,

6.5mm must be trimmed from the root of each upper wing half by a simple saw cut.

When the upper and lower wing halves are joined the protruding section of the

lower wing panel becomes a locating tongue that simply slips into place. While

this simple modification was carried out I took the opportunity to modify the

most obvious flaw in Revell’s pretty good kit – the fact that the wing dihedral

is far too shallow. This was corrected by making a saw cut the whole width of

the lower wing along the line of the dihedral break immediately outboard of the

inner engine nacelles. There is a clearly scribed line on the kit parts to guide

a saw cut. The corresponding upper surfaces were cut back about 5mm from the

leading and trailing

edges. The

upper and lower halves were then joined with tube cement and the wings bent

upwards to the correct angle. This allowed the saw cut in the lower wing panels

to open up and strips of 10 thou. and 5 thou. plastic card were slipped into

these slots to wedge them into the correct position. I used a wing from an

unbuilt Airfix Lancaster as a jig for this exercise, although it would have been

just as easy to line up the structure with a plan.

edges. The

upper and lower halves were then joined with tube cement and the wings bent

upwards to the correct angle. This allowed the saw cut in the lower wing panels

to open up and strips of 10 thou. and 5 thou. plastic card were slipped into

these slots to wedge them into the correct position. I used a wing from an

unbuilt Airfix Lancaster as a jig for this exercise, although it would have been

just as easy to line up the structure with a plan.

The wings were tightly taped and left to dry for a couple of days before

the surplus card was trimmed away to leave a neat and strong joint. I have read

in some sources that the outboard engine nacelles may need to be trimmed to

shape to seat square on the more steeply angled wings but mine seemed just fine.

The inner nacelles can be added at the same time, incorporating rib detail in

the wheel wells. Thankfully Revell’s construction methods mean that the landing

gear can be added later.

A small point to check with a donor kit is to ensure that cable cutters

in the wing leading edge are eliminated, since they are only applicable to a

bomber wing.

The resin horizontal tail sections are designed to plug into recesses in

the rear fuselage and simply secured with superglue. The fin/rudder units were

added after painting.

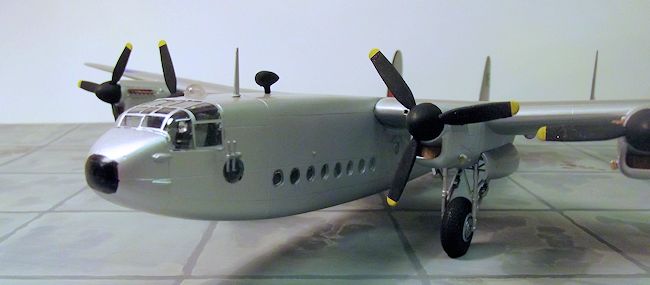

| COLORS & MARKINGS |

Many Yorks were operated in a polished natural metal finish although

some sources suggest that some examples were painted in high speed silver.

Polished natural metal is one of the nightmare finishes that I try to avoid, so

I contented myself with the thought that a well-used example on the Berlin

airlift would be pretty dull through constant use, and settled for a basic

overall finish of Tamiya XF-17 Flat Aluminium fixed with two brushed coats of

Future/Klear and finished with a spray coat of Xtracrylix Semi-gloss varnish.

The propellers

and

spinners were finished in Tamiya XF-1 Flat Black. Main painting was carried out

with my Iwata HP-C airbrush.

and

spinners were finished in Tamiya XF-1 Flat Black. Main painting was carried out

with my Iwata HP-C airbrush.

Decals

are commendably thin and sharply printed. CMR provide RAF roundels, codes and

serial numbers. My choice was that of a York from No. 242 Sqn. There is nothing

in the way of airframe stencilling or wing walk lines, but it appears that

natural metal aircraft had little in the way of such. They went on easily but

need care, since they are so thin that there is a tendency for them to fold over

as they are slid off the backing sheet. They reacted well to Micro Sol and Micro

Set decal fixing solutions. A final coat of semi-matt varnish sealed the decals.

| FINAL CONSTRUCTION |

The main sub-assemblies now comprised the fuselage and tail, and the wings with engines attached. The main airframe was assembled for the first time, adding the tail fins and left to set over a couple of days. The main wing to fuselage joint was secured using Devcon two part epoxy resin glue. I then added the main undercarriage and doors from Revell, incorporating the resin main wheels.. Finally the engine exhausts, propellers, fuselage aerials and wing tip lights completed assembly.

| CONCLUSIONS |

This build was inspired by my having seen the World’s two preserved

Yorks , one at the Imperial War Museum at Duxford and the other at the RAF

Museum, Cosford, both in England.

CMR provide a package that is among the very best available,

comprehensive and of high quality. My only niggle is the curse of the vacuform

transparencies since they test my limited skills far too much for comfort.

Thankfully, CMR were more than helpful in coming to the rescue when my first two

attempts went horribly wrong. It is a welcome addition to my slowly growing

collection of aircraft from the Lancaster family. I found it to be a rewarding

project and one that is highly recommended.

| REFERENCES |

Profile No. 168, The Avro York, by Donald M.Hannah. Profile Publications

Ltd., 1967

Avro York in Royal Air Force Service 1942-1957,

by Chris

Ashworth. Hall Park Publications Ltd., 1988

Avro Lancaster, Lincoln and York in post-war RAF service 1945-1950, by

Martin Derry. Dalrymple and Verdun Publishing,

2010.

March 2014

If you would like your product reviewed fairly and fairly quickly, please contact the editor or see other details in the Note to Contributors.