Airfix 1/48 Spitfire Vb/trop

| KIT #: | A05125 |

| PRICE: | £16-99 |

| DECALS: | Two options |

| REVIEWER: | Frank Reynolds |

| NOTES: |

| HISTORY |

The Spitfire Vb was the first major upgrade of the Spitfire

series following lessons learned in combat during the Battle of Britain

in 1940. Fitted with a Merlin 45 engine of 1470hp the wing profile was

changed by the installation of

a 20mm cannon in each wing, which

replaced the inboard pair of .303in machine guns. The cannon

installation required the provision of very distinctive blister fairings

to the upper and lower wing surfaces. In order to adapt the type for

operations in desert conditions a very distinctive lower nose profile

incorporated a large air filter and an enlarged under wing oil cooler

was fitted. On late build Vbs the windscreen and pilot’s hood were

modified to a more aerodynamic shape. The combination of these factors

resulted in a very different looking Spitfire from the sleek point

defence interceptor that had entered RAF service in 1938.

By

September 1943 twenty seven RAF squadrons were operating Spitfire Vbs .

As later Spitfires entered service, well used and war weary Vbs were

transferred to overseas areas of operations and to other air forces. Vbs

were found in the inventory of the South African Air Force, Turkey and

Yugoslavia, all of whom had influence in the Mediterranean Theatre of

World War 2.

By

September 1943 twenty seven RAF squadrons were operating Spitfire Vbs .

As later Spitfires entered service, well used and war weary Vbs were

transferred to overseas areas of operations and to other air forces. Vbs

were found in the inventory of the South African Air Force, Turkey and

Yugoslavia, all of whom had influence in the Mediterranean Theatre of

World War 2.

It is the air force of Turkey that provides the interest for

this project, a service that has the intriguing claim to fame of being

the only one to simultaneously operate the Spitfire and Focke Wulf

Fw-190 in its fighter squadrons. A neutral country in World War 2,

Turkey was able to accept deliveries of war material from both sides of

the conflict.

Turkey initially accepted three Mk.1 Spitfires in late 1939, but

further deliveries were delayed until 1944, after some years of

negotiations to persuade Turkey to cut off trade and diplomatic

relations with the Axis Powers. A total of 105 aircraft were supplied,

some 36 Mk.Vb and 69 Mk.Vc. Drawn from RAF Middle East stocks many were

well-used and in poor condition when delivered and they were used

primarily for training by the 5th

and 6th Air Regiments. The

Vbs were withdrawn in 1948 and the Vcs a year later.

When modelling a Spitfire V, good reference sources are

essential to get the right combination of features and it will always be

a trap for the unwary. Sometimes the only answer is an inspired guess.

| THE KIT |

This

new tooling is supplied in Airfix’s now standard top opening box with a

rather flimsy lid. There are five parts frames in pale blue plastic and one

of clear.

The parts are very cleanly moulded with no evidence of flash

or sinkage and are beautifully engraved with sharp clean panel lines and

subtle fabric texture to the rudder and elevators. The transparent parts are

reasonably well done but there is some distortion visible in the cockpit

hood mouldings.

This

new tooling is supplied in Airfix’s now standard top opening box with a

rather flimsy lid. There are five parts frames in pale blue plastic and one

of clear.

The parts are very cleanly moulded with no evidence of flash

or sinkage and are beautifully engraved with sharp clean panel lines and

subtle fabric texture to the rudder and elevators. The transparent parts are

reasonably well done but there is some distortion visible in the cockpit

hood mouldings.

Instructions consist of a 14 page

booklet with construction steps set out in

46 pictorial stages keyed to CAD drawings with the relevant parts colour

coded to each stage

| CONSTRUCTION |

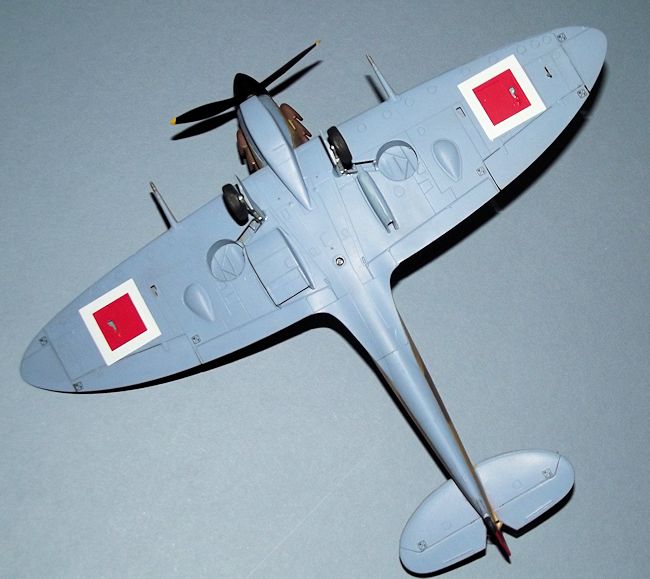

This is my second version of Airfix’s recently released Spitfire Mk.Vb, the

first of which was reviewed on MM on 02 September 2014. This project

represents the “other version” offered by Airfix,

a Mk.Vb/Trop

incorporating the massive chin air intake/filter, the later type windscreen

with more bulged cockpit hood and the large Rotol propeller.

Construction

begins with the interior, which features separate cockpit side walls which

also form the interior of the lower fuselage. There are four bulkheads

providing the engine firewall, instrument panel, pilot’s seat support and

headrest support. The seat is well detailed with separate sides, rear armour

plate, seat frame and head rest. Well detailed levers, pedals, trim wheels

and oxygen bottle are separately moulded. The cockpit interior was finished

in Xtracrylix XA1010 Interior Grey Green, with the section aft of

the seat

in Tamiya XF-16 Flat Aluminium. The instrument panel, control boxes and

handles were picked out in Flat Black. The kit provides an effective decal

for the instrument faces and seat belts were fashioned from painted masking

tape.

the seat

in Tamiya XF-16 Flat Aluminium. The instrument panel, control boxes and

handles were picked out in Flat Black. The kit provides an effective decal

for the instrument faces and seat belts were fashioned from painted masking

tape.

The lower wing is a full span section and in a departure from Airfix

tradition, the flaps are moulded in place, with no option for dropped flaps

available.. The walls to the circular wheel wells are glued to the lower

surface. The wing is provided with front and rear stub spars that span

between the wheel wells and help to set up the correct dihedral. An unusual

undercarriage arrangement has been tooled, whereby each leg has an angled

pintle (stub) at the top of the leg that fits into the rear face of the

front spar, the remainder of the gear leg is to be added later. The spars

and leg stub/pivot were found to be a very close fit and some shaving and

fettling of the parts was necessary. I chose to add the lower wing section

to the underside of the fuselage and then add the separate left and right

upper wing mouldings. The upper wing panels incorporate the elliptical tips.

Airfix have moulded two prominent strengthening strips on the upper surface

of each wing, a feature that is not found on all Mk.VBs. Having established

that they were not applicable to the Turkish machine being modelled, I

carefully carved the strips away, using a fresh scalpel blade. The ailerons

are separate and very finely cast. There is minimal joining area between the

ailerons and the wing

cut out so they are vulnerable to breakage and I had

to re-glue each one after some careless handling during construction.

cut out so they are vulnerable to breakage and I had

to re-glue each one after some careless handling during construction.

The horizontal tails consist of separate upper and lower surfaces that fit

positively into sockets in the fuselage. The elevators are a one piece

component with a central joining bar. I find it easier to cut the two

elevator sections apart and to line them up when gluing either side of the

tail fin. The one piece rudder can now be added and the various flying

surfaces checked for alignment.

The lower section of the engine cowl needed some adjustment to get it to

seat into the leading edge of the wing.

The under

wing radiator and oil cooler show the degree of sophistication that is found

in current Airfix kits with moulded fine mesh detail inside the components

and a positionable outlet door on the radiator housing. These parts fit

snugly into positive recesses in the lower wings.

The canopy was added and I chose the closed option, not forgetting to add

the gun sight before the canopy went on. The hood and fixed rear section are

supplied in one piece, with a separate windscreen. They fit snugly and were

secured with Airfix Clearfix glue, then masked with Tamiya tape trimmed with

a fresh scalpel blade. Next I added the wing cannon.

The propeller assembly has a positive keying system to prevent the blades

from being assembled backwards. The spinner was painted Sky in Xtracrylix

XA1007

, with the blades in Flat Black and tips picked out in Yellow. The prop

assembly was set aside while painting was carried out.

| COLORS & MARKINGS |

The colour scheme was taken from Tigerhead Decals sheet 48008 “Spitfires and

Wurgers of the Turkish Air Force” which I obtained from Hannants in the UK

at a reasonable £10-50

The colour scheme was taken from Tigerhead Decals sheet 48008 “Spitfires and

Wurgers of the Turkish Air Force” which I obtained from Hannants in the UK

at a reasonable £10-50

The decals are well printed in good register and packed with a small header

card that simply shows side views of three of the five colour schemes. I

queried this with Hannants and it seems that the full instructions are

available on Tigerhead’s web site as a download – duly obtained as a pdf.

The aircraft is finished in the standard RAF-style desert scheme of the era,

the underside airbrushed in Xtracrylix XA1026 Azure Blue, the upper surfaces

shadow shaded in Xtracrylix XA1009 Middle Stone and XA1002 Dark Earth. The

upper colours were divided with sausages of Blu-tack to provide a slightly

feathered camouflage demarcation line. The rudder was picked out in Tamiya

XF-7 Flat Red over a white undercoat and the propeller assembly in XF-1 Flat

Black. All of the paint was applied with my Iwata HP-C airbrush. The whole

airframe was then brushed with Future/Klear floor polish to provide a good

base for the decals.

The aircraft is finished in the standard RAF-style desert scheme of the era,

the underside airbrushed in Xtracrylix XA1026 Azure Blue, the upper surfaces

shadow shaded in Xtracrylix XA1009 Middle Stone and XA1002 Dark Earth. The

upper colours were divided with sausages of Blu-tack to provide a slightly

feathered camouflage demarcation line. The rudder was picked out in Tamiya

XF-7 Flat Red over a white undercoat and the propeller assembly in XF-1 Flat

Black. All of the paint was applied with my Iwata HP-C airbrush. The whole

airframe was then brushed with Future/Klear floor polish to provide a good

base for the decals.

The decals went on fairly easily assisted with Micro Sol and Micro Set.

Tigerhead provide only the main national markings and codes but the photos

that I have seen indicate that the Turkish Spits had little in the way of

obvious stencilling. Wing walk lines came from the Airfix decal sheet and I

added a few of their RAF-type stencils to the underside to break the

monotony of the all-blue paintwork. The decals were sealed with an

airbrushed coat of Xracrylix XFF Flat varnish.

| FINAL CONSTRUCTION |

The undercarriage is added next but Airfix’s approach to the assembly far

from conventional and demands care. The join between the undercarriage legs

and the pintle/stub arrangement housed in the wing is shallow and

potentially weak. It is definitely not novice friendly. The main leg and

in-wing stub each have a flat section cut onto them to serve as a half

lapped joint. At the same time the instructions show that each leg has to be

angled forward by 77 degrees and set up at 93 degrees splay to the wing

under surface. I left t he wheels off to avoid a dead weight on the end of

the legs while I tacked then in place with tube cement and then pushed and

prodded them for about half an hour while waiting for the cement to go off,

constantly checking the legs’ alignment against the drawings in the

instructions.

he wheels off to avoid a dead weight on the end of

the legs while I tacked then in place with tube cement and then pushed and

prodded them for about half an hour while waiting for the cement to go off,

constantly checking the legs’ alignment against the drawings in the

instructions.

I still wonder whether this clever arrangement is over-engineered. In about

60 years of plastic kit production most manufacturers seem to agree that the

easy way to secure a single leg undercarriage is to have a peg on top of the

leg and a socket in the wing. It is a reasonably strong system and virtually

self-aligning. It is even a system that Airfix use in their relatively

recent 1:48 scale kits of Spitfire XII, Spitfire XIX, Seafire XVII. I still

prefer that traditional arrangement. Left overnight to dry the legs still

looked fragile so I extended the upper edge of the gear doors with a sliver

of 20

thou. plastic

card. This enabled me to glue the doors to both the wing underside and the

legs and stiffen up the structure. The wheels were added once I was

satisfied that the undercarriage structure had well and truly set hard.

| CONCLUSIONS |

In spite of the irritation with the undercarriage

assembly I still rate this as a great kit.

In spite of the irritation with the undercarriage

assembly I still rate this as a great kit.

Teamed with the Tigerhead decals it makes an interesting and unusual subject and comparison with the standard Mk.Vb makes an interesting contrast in configuration. The kit is comprehensive, and a lot of thought has gone into its design. It repays careful work but it is not a kit for a beginner. The only filler needed was the slightest trace along main joint lines. Highly recommended and, for what is on offer, amazing value for money.

| REFERENCES |

Aeroguide Classics Number 1, Supermarine Spitfire Mk

V. Linewrights Ltd 1985.

Spitfire in Action. Squadron Signal Publications

1980.

Supermarine Spitfire. Ducimus Books Ltd 1970.

Spitfire International, by Helmet Terbeck, Harry Van

der Meer and Ray Sturtivant, Air-Britain Publications 2002

November 2014

If you would like your product reviewed fairly and fairly quickly, please contact the editor or see other details in the Note to Contributors.