Monogram 1/48 B-17G Flying Fortress

| KIT #: | 5600 |

| PRICE: | $19.96 MSRP |

| DECALS: | Two options |

| REVIEWER: | Bruno Schielzeth |

| NOTES: | The inside story |

| HISTORY |

The Boeing B-17 was, arguably, the most

famous Allied heavy bomber of WWII. It didn't carry the largest bomb

load, or fly the fastest, but it was rugged and beloved by its crews. From

the original Model 299 to the final version, the B-17G, it fought from

first day to the last day of the war in every theater. Thousands of men

lived, fought, and died in the remarkable Boeing B-17.

Because it didn't have the range to fly the vast expanses of the Pacific

Ocean most B-17s were sent to the European theater where they served with

distinction and proved the name “Flying Fortress” was not just a name but a

fact.

The Boeing B-17 was, arguably, the most

famous Allied heavy bomber of WWII. It didn't carry the largest bomb

load, or fly the fastest, but it was rugged and beloved by its crews. From

the original Model 299 to the final version, the B-17G, it fought from

first day to the last day of the war in every theater. Thousands of men

lived, fought, and died in the remarkable Boeing B-17.

Because it didn't have the range to fly the vast expanses of the Pacific

Ocean most B-17s were sent to the European theater where they served with

distinction and proved the name “Flying Fortress” was not just a name but a

fact.

Not all of the mighty bombers left

the shores of America to battle the Axis military machine. A number of them

served in anti-submarine and search and rescue operations on all the

seacoasts of the USA. One of them was a Boeing B-17G-60 BO 42-102823

nicknamed Murph by its crew. It flew anti-submarine patrols out of Florida

from early 1943 to the end of hostilities in April, 1945. Among the crew

was my father, Bruno P. Schielzeth. Bruno emigrated from Kiel, Germany in

1938. He was still a German citizen at the time and was barred from serving

in the European theater because of this. He was the tail gunner on Murph.

Not all of the mighty bombers left

the shores of America to battle the Axis military machine. A number of them

served in anti-submarine and search and rescue operations on all the

seacoasts of the USA. One of them was a Boeing B-17G-60 BO 42-102823

nicknamed Murph by its crew. It flew anti-submarine patrols out of Florida

from early 1943 to the end of hostilities in April, 1945. Among the crew

was my father, Bruno P. Schielzeth. Bruno emigrated from Kiel, Germany in

1938. He was still a German citizen at the time and was barred from serving

in the European theater because of this. He was the tail gunner on Murph.

Murph flew from Jacksonville, Florida looking for German submarines along the South-Eastern shipping lanes. Most of the long patrols consisted of hours and hours of boredom and open seas. Most, but not all. At least one German submarine Commander stayed on the surface and attempted to fight Murph one on one.

My father's account, as I remember it, is that a German submarine was sighted off of the Carolina coast late in the day. Because of either mechanical problems or just stubborn determination the submarine didn't submerge as Murph began its attack out of the setting sun. As the bombardier lined up on the target every anti-aircraft gun on the sub opened up on Murph. The sub gunners were accurate and got several hits on Murph. At least one shell hit the tail gunner's position as my father received wounds in his legs from shrapnel and a bullet. My father still carried the shrapnel in his leg from that encounter when he died in 2001. The submarine dove as Murph came back for another pass and several depth charges were dropped near the sub. I believe it was claimed as a 'probable kill'.

On May 18, 1945, over two weeks after the German surrender, my father took a number of pictures of Murph and the crew he served with while they were stationed in Avon Park, Florida. Almost 60 years later those pictures made their way to me.

| THE KIT |

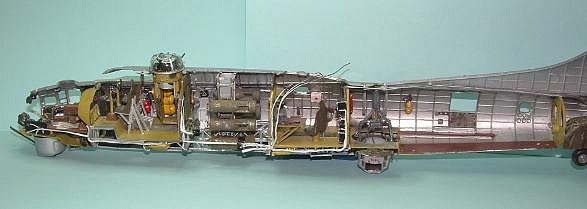

(Editor's Note: I've

decided to show the images as if going from the front to the back. It seems

the most logical way to do the things so images may not correspond with the

surrounding article.)

Looking at the pictures I knew I had to build a model of my father's

airplane. Luckily the venerable Monogram B-17G Flying Fortress #85-5600 is

a very close match for an early 60 series B-17G with the large waist gun

windows directly opposite of each other. It was the same kit I used as a

lad of 16 to build my first model of my father's plane. It is still, after

more than 40 years of production, the only 1/48th scale B-17G available.

Thank goodness the molds have held up because the kit is still fun to

build!

(Editor's Note: I've

decided to show the images as if going from the front to the back. It seems

the most logical way to do the things so images may not correspond with the

surrounding article.)

Looking at the pictures I knew I had to build a model of my father's

airplane. Luckily the venerable Monogram B-17G Flying Fortress #85-5600 is

a very close match for an early 60 series B-17G with the large waist gun

windows directly opposite of each other. It was the same kit I used as a

lad of 16 to build my first model of my father's plane. It is still, after

more than 40 years of production, the only 1/48th scale B-17G available.

Thank goodness the molds have held up because the kit is still fun to

build!

This time I was going to build it right. No hand painted numbers on the tail, no sloppy silver paint from a rattle can. With 30 odd years of modeling under my now much expanded belt, I was going to do it right, no matter what it took.

Step one was digging out my credit

card and making an order from Squadron. I ordered the Monogram kit, the

Verlinden update set #718, the Eduard armament set #48 209, and the

Squadron Crystal Clear Canopies sets for the B-17G. While I waited for my

order to arrive I scanned my father's pictures into the computer and spent

hours searching the web for information and reference material.The US Army

Air Force site at

http://www.armyairforces.com/ was helpful in tracking the serial number

of Murph, and the forum section was a good place to look for information on

the other crew members but, sadly, nothing has surfaced so far. If anyone

has any ideas of how to track down any of the following people, please feel

free to let me know!

Step one was digging out my credit

card and making an order from Squadron. I ordered the Monogram kit, the

Verlinden update set #718, the Eduard armament set #48 209, and the

Squadron Crystal Clear Canopies sets for the B-17G. While I waited for my

order to arrive I scanned my father's pictures into the computer and spent

hours searching the web for information and reference material.The US Army

Air Force site at

http://www.armyairforces.com/ was helpful in tracking the serial number

of Murph, and the forum section was a good place to look for information on

the other crew members but, sadly, nothing has surfaced so far. If anyone

has any ideas of how to track down any of the following people, please feel

free to let me know!

Pilot: 1st Lt. Dobbs.

Co-pilot: Lt. Vreland or Vrelind. The spelling is unclear on the picture

(my father had horrible hand writing!)

Bombardier: “Smythie” no other name known.

Armorer: Richard Bennett, “Benny” from New York (city?)

Flight Engineer: W.R. Hurig (? spelling again)

Lower ball turret gunner: John Nitecowitcz, “Nick” (? spelling again),

Navigator: George Hemstead

Radioman: “Fisher” no other name known.

Waist gunner: Lowell Ball.

Tail gunner: Bruno Schielzeth

In order to build the Murph as accurately as possible I also accepted help

from a few dear modeling friends. The late, and much missed, Garry Beebe

supplied Roger A. Freeman's 'B-17 Fortress at War' and Denis Keegan from

Canada pulled some strings with Dave Parkins of FlightPath to get a sheet

of his out of production B-17G Photo etched details from Dave's private

stash.

| CONSTRUCTION |

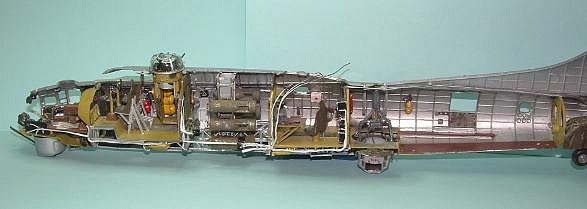

I noticed from my father's pictures

that Murph was mostly lacquered aluminum inside. The cockpit appeared to be

dark, and was probably chromate green, with olive drab for the armor plate,

but the rest of interior shots seem to show aluminum with possible chromate

green frame members. It would certainly make the interior of the model

brighter and more colorful!

I noticed from my father's pictures

that Murph was mostly lacquered aluminum inside. The cockpit appeared to be

dark, and was probably chromate green, with olive drab for the armor plate,

but the rest of interior shots seem to show aluminum with possible chromate

green frame members. It would certainly make the interior of the model

brighter and more colorful!

Since Murph did not operate at 30,000 feet, and was based in an almost tropical climate, there did not appear to be any of the insulated quilted batting applied to the outer walls. I began the build, as usual, with the cockpit. I assembled the Monogram flight deck and painted and detailed the instrument panel to match photo references.

I added the engine controls to the center console from thin wire pieces with a drop of Testor's Clear Parts cement on the ends to create the knob. A small drop of the appropriate color of paint put on with the end of a sharp toothpick finished them off properly. I added the auxiliary instruments to the top of the instrument panel and wired them with .010 electrical solder but otherwise left the cockpit as it came from the box.About this time my idea about the build changed dramatically. I think it started out innocently enough. I just held up the FlightPath cockpit framing to the fuselage and thought I would like to open up the pilot's window as shown in my father's pictures. That should be easy enough to do, right? Well, I guess I should detail the turret area behind the cockpit since it would be very visible. As long as I was working on that, why not dress up the bombardier's and navigator's areas a little too? The Verlinden resin might as well be used, right? As I said, it started off innocently enough, but the “as long as I'm doing this I might as well.....” thought can cause a lot of extra work!

After adding all the bits and pieces

per the Verlinden instructions I looked at the finished flight deck. Very

nice! Except for a few little things. I compared my flight deck with Dad's

pictures and my collection of reference material. The Monogram part is a

good representation of a generic B-17, but it certainly didn't match what I

saw in the pictures!

After adding all the bits and pieces

per the Verlinden instructions I looked at the finished flight deck. Very

nice! Except for a few little things. I compared my flight deck with Dad's

pictures and my collection of reference material. The Monogram part is a

good representation of a generic B-17, but it certainly didn't match what I

saw in the pictures!

A moral dilemma ensued. Do I leave it 'as is', or do I tear out a week's worth of work and make it match the pictures?

Gritting my teeth, I grabbed my tools and tore the flight deck apart and carved off most of the cast in details! I then opened up the access panel in the cockpit deck and the canvas curtain to the navigator's and bombardier's areas. That required that I add some detailing to the now exposed crew's tunnel. In went various bits and pieces of styrene I- beams and lots of stretched sprue, plus some oxygen tanks salvaged from a Monogram B-29 kit and kindly supplied by fellow modeler Terry (who should be working on models) Moore.After 'deconstruction' I added the Verlinden resin bits, electrical solder, stretched sprue, and PE switch panels from Reheat to the flight deck until it matched my father's pictures and the other references I had on hand.

I built up an APU (Auxiliary Power Unit) from the engine of a 1/72nd scale Kubelwagen engine and scrap plastic and stationed it against the aft cockpit bulkhead behind the co-pilot's seat. The APU placement varied from plane to plane and I've seen them in the cockpit, in the bomb bay, in the radio room, in the tail, and under the decks, I just guessed on Murph and installed it where I did because there was room there and it looked pretty barren.

That decision to rebuild the flight

deck affected the entire rest of the model. Once the flight deck was

looking so good I couldn't just slap the rest of the kit together.

That decision to rebuild the flight

deck affected the entire rest of the model. Once the flight deck was

looking so good I couldn't just slap the rest of the kit together.

The Turrets.

I was going to use the Squadron vacuformed turrets, but I wanted to use the

FlightPath PE framing. The FlightPath PE is designed for the Monogram parts

and wouldn't line up properly on the Squadron parts. Rather than modify the

excellent FlightPath PE I ended up sanding off all the framing on the kit

turrets.

It really wasn't as bad as it sounds, but it does take courage to take a 150 grit sanding stick to clear parts! I could just image having to buy another kit just to replace the clear parts I ruined! I masked off the clear panels to protect them and sanded the parts until the framing was almost gone. I then began going to finer and finer grades of sand paper.

I finished sanding with Detail

Master's Micro-mesh cloths until I reached the 12000 grit cloth. A final

polishing with Mother's Mag Wheel Polish returned the clear parts to proper

clarity. A dip in Future sealed everything and gave me crystal clear

turrets.I then began to add some extras to the inside of the turrets.

Verlinden resin breeches, FlightPath PE heat shields soldered to .030 brass

tube, and scratch built parts like clear gun sights and new hand controls

from stretch sprue. The kit lower turret assembly didn't resemble the real

item at all so the only kit part used was the actual mounting ring. The

lower mount was fabricated out of rectangular styrene tube tapered to the

correct shape and then skinned in .010 flat styrene sheet. I cut some spare

gun heat shields to the proper shape and used them for the cooling grates

over the hydraulic pumps  and controls located in the 'legs' of the lower

mount. I also added foot supports and ammo bins. The upper half received

wire supports for the weather shields around the gun barrels and charging

handles made from scrap PE. The lower ball received scratch built ammo

bins, seat cushions, a clear gun sight, foot controls for the gun sight,

and an open hatch courtesy of the Squadron vacuformed ball turret.

and controls located in the 'legs' of the lower

mount. I also added foot supports and ammo bins. The upper half received

wire supports for the weather shields around the gun barrels and charging

handles made from scrap PE. The lower ball received scratch built ammo

bins, seat cushions, a clear gun sight, foot controls for the gun sight,

and an open hatch courtesy of the Squadron vacuformed ball turret.

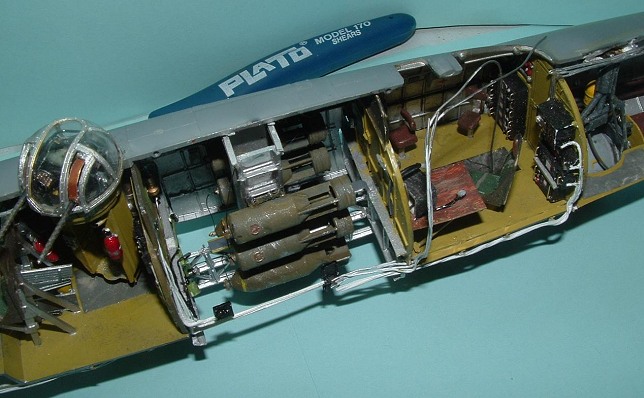

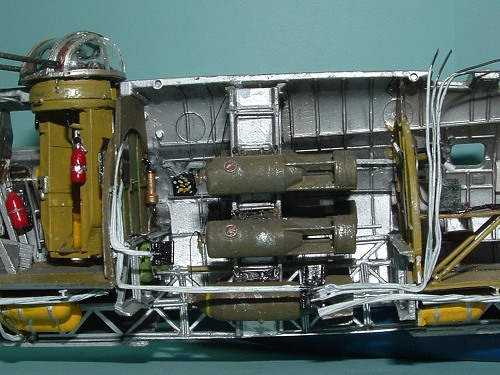

The Bomb Bay

My father's pictures of Murph on the ground showed the plane with the flaps

up and the crew doors all open. The bomb bay was also open. I'm sure it was

because Florida in May is very warm and they needed all the ventilation

they could get to keep the plane from becoming a roasting oven! That meant

that I would have to duplicate those features on my model.The bomb bay in

the kit is pretty bland. The bulkheads on either end are totally blank and

the center bomb rack is lacking in detail and rather thick. Since I planned

on showing the Murph with the FlightPath PE bay doors open, I needed to

detail it too.

My local hobby shop, Don's Hobby Shop in Kenosha, WI., supplied the Evergreen styrene trusses to build up a more detailed bay and Accurate Miniatures supplied the ordnance. I cut the Evergreen truss material to fit between the aft bulkhead of the radio room and the half bulkhead just under the cockpit. I used larger truss material to add the main wing spars to the fore and aft bulkheads of the bomb bay.

The center truss in my model isn't

totally accurate, as the real one is a single span, but I had to choose

between scratch building the entire thing or using a doubled up truss. I

built up the double truss and liked the looks of it, so I took the easy way

out.  I didn't like the look of the massive wing mounting lugs of the kit and

finally found a way to hide them. I used more .010 sheet styrene to cut a

panel that fit just below one of the stringers on the sidewall of the bay

and added .020 hex rod to match the spacing of the kit's ribs. I then

ground off all the ribs below the stringer with a Dremel motor tool and cut

the mounting lugs on the wing down to about half their normal depth. The

wing still slides in and locks the way Monogram intended, but the join is

now hidden behind the new sidewall.

I didn't like the look of the massive wing mounting lugs of the kit and

finally found a way to hide them. I used more .010 sheet styrene to cut a

panel that fit just below one of the stringers on the sidewall of the bay

and added .020 hex rod to match the spacing of the kit's ribs. I then

ground off all the ribs below the stringer with a Dremel motor tool and cut

the mounting lugs on the wing down to about half their normal depth. The

wing still slides in and locks the way Monogram intended, but the join is

now hidden behind the new sidewall.

My father's pictures showed a bomb

load of one 500 pound HE bomb with two depth charges above it on each side

of the center rack. The side racks carried two 250 pound HE bombs each.

Because I blanked in the sidewalls of the bomb bay I just didn't have the

room to mount the smaller ordnance on the side racks, but the overall look

is right I think. I detailed both bulkheads with styrene rod and various

bits and pieces of scrap plastic to duplicate the hydraulic motors and gear

boxes to open and close the bomb bay doors. If you look carefully you can

see that I even included the fuse safety retention wires.

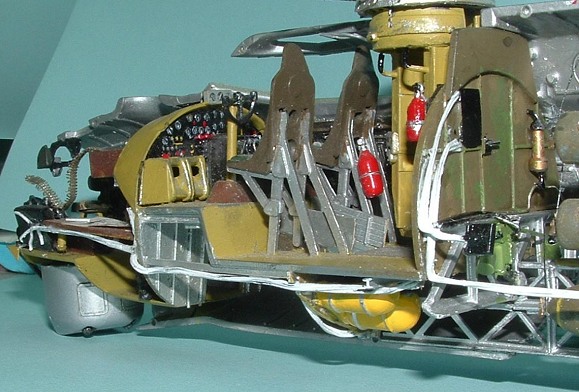

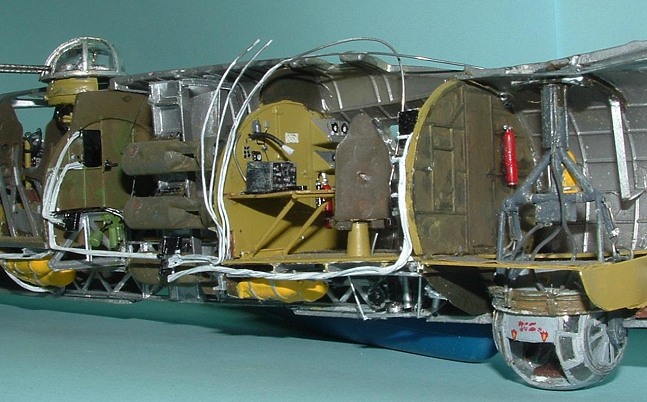

The Radio Room

I had already planned on

building up the radio room because of the large clear window in the top of

the fuselage. Now, considering the detail in the rest of the model, I had

no choice but to go all out on it. I started by cutting off all the radios

on the aft bulkhead. They were in very low relief but the real radios were

massive units almost 16 inches deep. I found styrene rectangular tube of

the proper dimensions and cut five boxes for the right rack and several

other ones for the left rack.

I had already planned on

building up the radio room because of the large clear window in the top of

the fuselage. Now, considering the detail in the rest of the model, I had

no choice but to go all out on it. I started by cutting off all the radios

on the aft bulkhead. They were in very low relief but the real radios were

massive units almost 16 inches deep. I found styrene rectangular tube of

the proper dimensions and cut five boxes for the right rack and several

other ones for the left rack.

I skinned the front of the boxes with .010 sheet plastic and then made scans of the original radios and reduced them to 1/48th scale on my computer. I printed them at full photo quality on my printer and glued them to the front of the radio boxes. I added knobs from stretched sprue. I then spent a night forming HO gage handrails into tiny stainless steel grab handles for the radios. Yes, I lost about 1/3rd of them to the infamous 'Carpet Monster'!

The kit radio room has a massive lump

to represent the desk and radio receiver. I cut it off of the deck and

filled the resulting hole with heavy sheet styrene. The new receiver was

fashioned from tube, and the desk was a sheet of styrene with supports from

.030 rod. I added a few runs of .010 and .020 electrical solder for the

wiring and antenna lines and added a few bits and pieces to the sidewalls

for some clutter. I then added two jump seats to the right side for the

waist gunners to use during takeoff and landings.

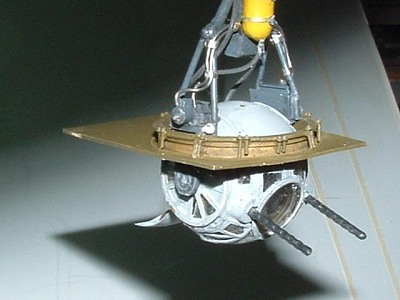

Mounting the Lower Ball Turret

Working towards the tail I now had to mount the ball turret I had detailed.

Would I use the kit part? No. Of course not! That would be too easy!

I did find one interesting thing

while researching the real ball mount. One of the flying B-17s out there

today has the mount from a B-24 in it! The Sperry ball turret is the same

in both planes, but the B-24 mount can retract the ball into the fuselage,

the B-17 mount is solid. I guess it just proves you have to research your

research!

I did find one interesting thing

while researching the real ball mount. One of the flying B-17s out there

today has the mount from a B-24 in it! The Sperry ball turret is the same

in both planes, but the B-24 mount can retract the ball into the fuselage,

the B-17 mount is solid. I guess it just proves you have to research your

research!

I kept the kit mount on the ball as I built up a new and more correct upper ball mount out of styrene rod of various sizes and then cut away 99% of the kit part.

Looking back I probably should have used soldered brass tube, as my plastic mount is very fragile. However, it does work and looks right. I added various bits of styrene tube and rod to duplicate the hydraulic motors and the control box on the mount and then added .010 solder for the hydraulic lines.

After the rebuild the yellow oxygen

tank and the pivot points are the only kit parts left! I built up the lower

ring mount from flat styrene stock around a properly sized bottle and added

dozens of Grant Line nut and bolt pieces to it. I then mounted the ball

turret into the fuselage. I built up the walkway around the ball with flat

stock and added used 2000 grit sandpaper for the anti-skid paint used on

the decks throughout the plane. The flexible lines to the ball turret for

the intercom, oxygen, and electricity were made from the soft rubber tube

in the Verlinden detail set. The lower turret still rotates and elevates as

it should.

The Ma Duces

The Monogram M-2 50 cal machine guns are actually very nice in this kit, so

I used the kit guns with the FlightPath shields over more .030 brass tube

for the barrels and the FlightPath PE gun cradles. My father's pictures

show that Murph had the new electronic auto-computing gun sights on the

waist guns, so I scratch built a pair of them out of clear rod sanded to

shape and painted. I added those to the two waist guns but I left the cheek

guns with just the ring and bead sights. I also added styrene blocks for

the gun heaters and used more of the Verlinden rubber tube for the shock

mount cords used to keep the guns secured when not in use.

The Monogram M-2 50 cal machine guns are actually very nice in this kit, so

I used the kit guns with the FlightPath shields over more .030 brass tube

for the barrels and the FlightPath PE gun cradles. My father's pictures

show that Murph had the new electronic auto-computing gun sights on the

waist guns, so I scratch built a pair of them out of clear rod sanded to

shape and painted. I added those to the two waist guns but I left the cheek

guns with just the ring and bead sights. I also added styrene blocks for

the gun heaters and used more of the Verlinden rubber tube for the shock

mount cords used to keep the guns secured when not in use.

Going over the edge

After I had the plane built and detailed back to the waist gunner's area I

decided to add just a little extra detail. I put in two scratch built

strike cameras under the radio room floor, one a 35 mm still camera, the

other a 70mm film camera. I also added more oxygen tanks and framing

detail, added wiring harnesses, oxygen and hydraulic lines, and flight

cables.

I have a long way to go before I'm

done with the inside of Murph, and I still have the entire outside of the

airplane to do! The plans include opening up one of the engine nacelles to

show off a fully detailed Wright Cyclone R-1820 radial engine and detailed

wheel wells. I guess that will have to wait until part 2 of this build.

I have a long way to go before I'm

done with the inside of Murph, and I still have the entire outside of the

airplane to do! The plans include opening up one of the engine nacelles to

show off a fully detailed Wright Cyclone R-1820 radial engine and detailed

wheel wells. I guess that will have to wait until part 2 of this build.

A Thank You

I need to thank Scott Van Aken for his courage to show a half completed

model on Modeling Madness.

I also would like to thank Mike Horrell, 'Crazy Don' Flynn, Larry Goodell,

Lynn Ritger, and all the rest of the crazy gang at the modeling sites I am

a member of for pushing me to make this build public.I need to also thank

my long suffering and very understanding partner in life, Cindy, for

putting up with spray paint fumes in the bedroom, glue marks on the bed

spread, and my demented fascination with little plastic toys. Like she

says, “At least I know where you are and what you are doing. Besides, it's

cheaper and safer than you sitting in a bar all night”. Truer words have

never been spoken!

Suggestions, criticisms, and help in locating the members of Muph's crew

are gladly accepted at

Bschielzeth1@wi.rr.com

If you would like your product reviewed fairly and fairly quickly, please contact the editor or see other details in the Note to Contributors.