Xotic 72 1/72 Goodyear F2G Corsair

|

KIT # |

4805 |

|

PRICE: |

$19.95 |

|

DECALS: |

Four aircraft |

|

REVIEWER: |

|

|

NOTES: |

Short run with etched fret and vac canopy |

|

HISTORY |

|

THE KIT |

The $20 price tag for a 1/72 single-engine WWII fighter is likely to cause

“sticker shock” to those of us Auld Pharts who cut our modeling teeth on

50-cent Hawk, Revell, and Airfix Corsairs. But a look at the kit’s contents

reveals that the price isn’t really that bad. Other 1/72 Corsair kits retail

for between six and twenty dollars--let’s call $9 a fair average--and the

Xotic kit includes, besides the “basic” model:

*A fret of photoetched detail parts

*Film instrument panel

*Not one but two resin extended cowling scoops for the racers

*Vacform canopy

*Full-color painting/marking guide

*Detailed marking and conversion instructions

*Six black and white photos of several F2G racers

*Two sheets of excellent decals for four versions

So there’s really nothing else you need to buy. Add up what you’d normally

spend on resin, PE, vac, aftermarket decals, etc. for a typical $9 kit and

you’ll see that for what you’re getting, $20 isn’t a bad price at all. This is

a very complete package. For a look at what is in the box, please

visit the preview.

|

CONSTRUCTION |

Fuselage

Preparation

The fin of the Xotic F2G is offset a bit, just like the real one. In

dry-fitting the fuselage halves, I found I had to do some careful trimming

with an Xacto blade at the forward edge of the fin, where it meets the

fuselage, on both halves to get them to mate up. That done, the fuselage

halves required only a few careful swipes with Snake’s BAF (Big-Ass File, a

genuine Sears Craftsman 10” single-cut fine-cut mill file--ask for it by

name!) to mate up perfectly. I was pleased to find both fuselage halves the

same length, and to see that all fuselage panel lines matched up side-to-side,

something you don’t see in all limited run

kits.

The fin of the Xotic F2G is offset a bit, just like the real one. In

dry-fitting the fuselage halves, I found I had to do some careful trimming

with an Xacto blade at the forward edge of the fin, where it meets the

fuselage, on both halves to get them to mate up. That done, the fuselage

halves required only a few careful swipes with Snake’s BAF (Big-Ass File, a

genuine Sears Craftsman 10” single-cut fine-cut mill file--ask for it by

name!) to mate up perfectly. I was pleased to find both fuselage halves the

same length, and to see that all fuselage panel lines matched up side-to-side,

something you don’t see in all limited run

kits.

(Image to right) Xotic kit accurately captures the taller fin of the F2G. Compare to

Italeri F4U-5 in background.

The cowling gills are molded closed on their backsides with a bit of irregular

flash. It required only about 20 minutes’ work with an Xacto knife to open

these up. Curiously, the kit gives you no exhaust pipes, but they should be

easily added at some future time (I didn’t do so for this mostly out-of

the-box review).

The tailgear well was a bit too wide for the fuselage. I had to thin it a bit

in the rear to keep it from holding the fuselage halves apart. When it was

fitted and glued in, cockpit work could proceed.

Cockpit:

The kit provides a basic cockpit assembly comprising floor, seat, side

consoles, instrument panel, and joystick. You’ll have to drill out the hole in

the floor to mount the joystick. The instructions are a bit vague as to the

relationship of the side consoles and the floor--do they fit into the

perfectly sized notches in the side of the floor, or should they sit on top of

the floor? After trying the former, and finding that the instrument panel now

had no place to mount, I quickly unglued the consoles and mounted them atop

the floorboard, where they belong. The instrument panel then glues to the

forward edges of the consoles. The gluing surface here is tiny, so I

reinforced the panel/console joints on their back sides with Loctite superglue

gel.

The kit includes a number of photoetched details for the cockpit--instrument

panel, rudder pedals, console tops, etc., and a “film” for the instrument

faces. In the interests of keeping this project moving, I elected not to use

them. Personally, I don’t waste too much time detailing 1/72 cockpits, and

would have been just as happy to paint the inside of the fuselage flat black

and leave an open hole here, but since this is a review, I felt obligated to

report on the fit of the cockpit assembly, which is often a trouble spot in

these limited run kits. I’m pleased to report that the assembled ‘pit fits

onto the pegs molded in the inner fuselage halves just fine with no

interference whatsoever. I painted the entire cockpit area with Model Master

Interior Green FS34151, with flat black instrument panels, console tops, and

joystick handle.

Engine and Prop

There’s one more “little” detail before you can button up the fuselage, and

that’s the engine. Whoops! Somebody goofed up here big-time. The one-piece kit

engine bears no resemblance to the 28-cylinder (7x4) R-4360. There are nine

cylinders depicted, and the engine looks a bit like a “generic” R-2800 (9x2),

or the front bank of one. My spare parts box is not exactly overflowing with

surplus 1/72 R-4360s, and the kit engine fit so well in the spot indicated, so

I elected to use it and just painted the cylinders black so they can hide in

the shadows. Let the Mini-Maglite Police catch me if they can! (Yes, I am the

kind of guy whose initial response to any unusual car engine noise is to turn

the radio up!)

The engine comes with a stubby prop shaft molded into the gear case. The hole

in the prop was bigger than this shaft, so I cut if off and drilled out the

engine to take a piece of aluminum tubing to mount the prop.

The engine comes with a stubby prop shaft molded into the gear case. The hole

in the prop was bigger than this shaft, so I cut if off and drilled out the

engine to take a piece of aluminum tubing to mount the prop.

One final word about the kit engine if you choose to use it: Placed against

the nub molded in the right fuselage half, the engine was nicely positioned in

the cowling left-to-right and forward-and-backward, and caused no

interference with the installation of the left fuselage half. But after the

fuselage was together, I noticed that the engine is just a hair off in the

up-and-down axis, i.e., it sits just a little high. Mount yours as low as

possible in the fuselage without removing any of the engine’s backing plate

and yours should come out perfect.

The propeller is a nice representation of a Hamilton-Standard. It’s more

accurate in shape, in fact, than the propellers in either the Matchbox F4U-4

or the various Italeri 1/72 Corsair kits. It cleaned up nicely, and I used it

with no modifications whatever.

Fuselage

With tailwheel bay, cockpit, and engine installed in the right fuselage half,

it was time to button up the fuselage, which went off without a

hitch--excellent fit! Filler was required only at the forward edge of the

induction scoop on one fuselage half, where a chip was missing that looked

like someone had broken the part off a large sprue at this point. I filled the

little divot with Loctite superglue gel.

Note that F2Gs had two different tail gear configurations. The F2G-1, intended

for land-based use, carried no tailhook. It had no cutout in the tail cone for

the hook, like other Corsairs, and the tailwheel doors were only half the

“normal” length; behind the retracted tailwheel, the fuselage was solid with a

small fairing immediately aft of the tailwheel. The F2G-2 carried a more

normal Corsair arrangement, complete with tailhook and the cutout for it. The

kit has combined elements of both systems. All parts for the F2G-1 arrangement

are present, but so is the tailhook cutout in the rear fuselage. I did

not discover this anomaly until just before painting the model, and I had a

rather limited window of opportunity in which to paint it, so I had to press

on. Fortunately I discovered that the airplane I’d decided to model was indeed

an F2G-2 so the cutout was correct and

didn’t need to be filled, and I didn’t use the kit’s F2G-1 tail gear well

cover/filler piece, although I did use the kit’s short tail gear doors. (More

on this later.)

(Image to left) Kit features F2G-1 type tail gear and doors, but F2G-2 type tailhook

cutout in rear fuselage.

Canopy

The clear, cleanly formed and accurately shaped bubble canopy was separated

from its molding sheet with little problem. It fits the fuselage very well

fore and aft, but the lower edges don’t quite meet the mating surfaces

indicated on the fuselage sides. You can avoid this problem on yours by

cutting the lower edges a little lower than indicated and then carefully

trimming to fit the fuselage.

Horizontal Stabilizers

The stabilizers were okay and gave no problems except that the right one

wanted to mount with a noticeable bit of anhedral (droop). I fixed this in

just a few minutes by cutting a few degrees of angle at its root with the BAF.

(My customary building regimen is to mount the horizontal stabilizers and

square them to the fin before I glue the wing on, thus I can use all

three tail surfaces as a handy index of wing dihedral and alignment when I

mount it. Why I’m telling you this will become apparent in a few paragraphs.)

Wing

The wing looks nice at first, and its three parts fit well together, but it

has a number of problems.

First and foremost, the oil cooler intakes in the leading edges are the same

shape as for all production Corsairs, and this is not correct for the F2G

series. Joe Hegedus explained one way to fix this in his FSM article, but I

took an easier route. I cut and filed out the leading edge in the intake area

with the BAF, then inlaid chunks of styrene made by laminating three piece of

.020 strip together. When the cement had dried on these inlays, I shaped them

to match the wing leading edge, and then drilled and filed out the smaller,

egg-shaped F2G openings. Inside the opening I put...nothing! I did, however,

think ahead enough to paint the inside of the wing halves flat black before

gluing them together.

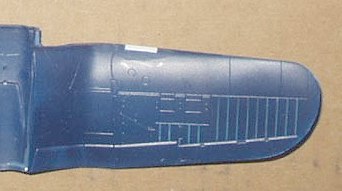

(Image to left) Laminated styrene blocks inlaid into oil cooler area of wing,

later filed to shape and opened up.

The F2Gs also did not have the radiator outlets on the bottom of the wing,

like all other Corsairs. I filed these off the kit parts. There is almost

enough meat in the plastic to get away with this, though it was rather thin in

places. In fact, my first layer of paint (thinned with lacquer thinner) ate a

small hole through the wing in this area, so I’d recommend reinforcing it with

putty, epoxy, or superglue on the inside before assembling your wing.

The kit

includes some nice photoetched faces for the oil cooler intakes, but because

they’re not of the right type for an F2G, of course I didn’t use them. They

might find their way onto another project at some point, though.

The wing’s second problem is very minor. It’s molded with openings for six

.50-cal guns. Not all the F2Gs were built with all six; some carried only

four. Check refs for the airplane you’re building and fill in the extra two

holes if needed. (Fill them all in if you’re building a racer!)

The third wing problem is a little more serious, depending on how serious you

take it. The F2Gs had the same fabric-covered outer panels found on all other

Corsairs through the -4, and the kit wing seems to represent metal-covered

outers as introduced on the -5.

Last summer I had the opportunity to examine and photograph the fabric wing

panels of the late, great Joe Tobul’s F4U-4 with an eye toward seeing how

these should be represented in scale. What I saw was not the classic

“ribs with fabric draped between them” look you might expect. The panels

appear to be more like panel lines right over the ribs, and the fabric did not

sag or bridge at all. In fact, the fabric appeared to be recessed slightly

right over the ribs.

(Image to right) Outer wing panel of real F4U-4, showing slight indenting effect over

ribs.

(Image to right) Outer wing panel of real F4U-4, showing slight indenting effect over

ribs.

I elected not to fix this area on this model, deciding that whatever I did, it

would be difficult to match the very delicate panel line engraving on the rest

of the kit’s surface. It’s not that difficult to fix, though, if you’re so

inclined. At the same time I built the Xotic F2G, I was also working on an

Italeri F4U-4B, which is also incorrectly molded with smooth wings. I cut some

strips of thick vinyl tape exactly .100 (1/10) inch and used these as scribing

guides, starting from the wingtip panel line and working inward,

“leapfrogging” two strips, one over the other, to set the spacing. The whole

job (all four panels) only took about a half an hour and the rib lines seem to

have come out exactly where they were supposed to. There’s no reason this

trick shouldn’t work on the Xotic F2G as well.

(Image to left) Italeri F4U-4 wing with fabric ribs scribed in.

(Image to left) Italeri F4U-4 wing with fabric ribs scribed in.

There are no details in the (unboxed) wheel wells, which bothers me not at

all, but will be of concern to you gear well freaks.

The wing’s final two problems are dihedral and fit to fuselage, which are

inter-related in a way. The wing seems to have just a bit too much dihedral in

the outer panels. It’s not a glaring problem unless you’re pretty seriously

into Corsairs, and/or display the finished model alongside another Corsair

kit. While pondering what if anything to do about this, I discovered that the

wing’s fit to the fuselage was a bit casual, with the wing mating up a bit

“cockeyed” when viewed from the front, and with noticeable gaps between the

wing and the fuselage on the topside at the roots.

Now I have something I use in my daily life I call “Snake’s Doctrine of

Competing Problems,” which states that if you have two or more problems in

your life, see if there’s any way you can play them off against each other and

solve them both. (It doesn’t always work, of course, but you’d be

surprised how often it can be invoked in matters of office politics or

family!) I realized that invoking SDOCP would provide a simple yet effective

solution to the dihedral and alignment problems. I securely cemented

the wing in place exactly where it “wanted” to go, without trying to fix it at

all. The right wing was visibly higher than the left. When it was very

dry, and the underside filled and mated, I made a thin wedge of sheet styrene

and inserted it at the right wing’s upper root/fuselage junction--there was

already a good-sized gap to be filled here, remember--and pushed it in until

it forced the right wing down into roughly equal alignment with the left, as

viewed against the horizontal stabilizers from both front and rear. I then hit

this wedge with a liberal application of Ambroid Pro-Weld, being careful to

keep the stuff out of the joint between the wedge and the fuselage. When the

cement was dry, I trimmed the excess wedge off the top of the wing with an

Xacto. Almost like magic, the wing now had a more proper degree of dihedral,

was properly aligned, and the gap on that side was filled. SDOCP wins again!

Don’t you love it when a plan comes together?

I filled

the upper wing root gap on the right side in my customary way, by filling the

joint with yellow carpenter’s glue and smoothing it with a licked fingertip

while still wet. There might be better ways to fill this kind of joint, but it

works well, and there’s nothing simpler or quicker!

I didn’t get quite enough of the dihedral out of the wing. Compared to a built

Italeri F4U-5, the Xotic F2G still has a little too much. It’s not as bad as

it was, but still noticeable to a sharp eye.

(Image to left) Dihedral is still a bit more than that of the Italeri F4U-5 in the

background. Also note black-painted nine-cylinder engine! (Editor

would like to point out that there is some parallax error in the image as

both aircraft are not being viewed from the same angle. Also note the

toed in landing gear of the upper plane indicating that perhaps the wings

were not installed at the correct angle. Just a thought.)

(Image to left) Dihedral is still a bit more than that of the Italeri F4U-5 in the

background. Also note black-painted nine-cylinder engine! (Editor

would like to point out that there is some parallax error in the image as

both aircraft are not being viewed from the same angle. Also note the

toed in landing gear of the upper plane indicating that perhaps the wings

were not installed at the correct angle. Just a thought.)

The kit doesn’t provide a pitot tube for the left wing, although one is

shown on the instruction sheet with an asterisks. Exhaust pipes are shown

with asterisks, too. I guess asterisk means “Get some plastic rod and make this

yourself, and this is where it goes.” I didn’t add any asterisk stuff for this

(mostly) out-of-box review.

After I’d gotten the wing fixed and glued securely on, my friend Joe

Hegedus suggested a possible fix for most of the wing problems that sounds

easy, elegant, and not too expensive. “Try using the wing from the Testor/Hawk

F4U-1A kit,” he offered. Hmmmmm. That wing has nicely engraved panel lines,

including the outer fabric ribbing; dihedral is better; and the oil cooler

intakes are molded solid, which means you can just drill and file them out to

the correct F2G shape. The kit currently retails for about $6. Could be a good

idea if the wing fits the Xotic fuselage cleanly--I couldn’t try it myself,

but you might want to investigate this idea.

(Image to right) From certain angles, the dihedral can look excessive. Note no pitot

tube is included in the kit.

(Image to right) From certain angles, the dihedral can look excessive. Note no pitot

tube is included in the kit.

Landing Gear, etc.

The main struts are pretty nice, with molded-in oleo scissors, and I think PE

scissors are included as well. The plastic parts required a good deal of

careful cleanup for flash. Also included are a pair of Y-shaped braces for

each strut, which will be familiar to builders of most good larger scale

Corsair kits. Sadly, these braces had no positive locating points, and after

about 15 minutes of fiddling with them, I gave up on them for the time being

and moved on. I hate little fiddly parts. Perhaps someday I shall have a fit

of industry and install them on the finished model.

The wheels aren’t bad, for a limited run kit. The spokes are a bit thin, but

if this bothers you, resin True Details replacements are available from

Squadron. I used the kit wheels, and I see from my photos that I got the left

one installed just a little pigeon-toed. I’ll fix that someday, too.

The tail gear is the F2G-1 type with no tailhook. Since the Corsair I modeled

is a hooked F2G-2, I’ll have to add a scratchbuilt tailhook to my list of

things to fix when I get around to it.

The tail gear is the F2G-1 type with no tailhook. Since the Corsair I modeled

is a hooked F2G-2, I’ll have to add a scratchbuilt tailhook to my list of

things to fix when I get around to it.

The main gear doors (wheel covers) are very nice, more detailed on their inner

faces than those in the Hasegawa 1/72 F4U-1 kit. The little front doors (strut

covers) had no positive locating points. Thank heavens for fast-drying

superglue.

The main struts mount to the wing at a near-perfect perpendicular angle. Note

that in profile, a Corsair’s landing gear is at a few degrees rearward rake to

the perpendicular. It’s not a huge point, but something to keep in mind if

you’re interested in “getting it right.”

(Image to left) Note F2G-1 tail gear, F2G-2 tailhook cutout, thin spokes on wheels,

and perpendicular mounting angle of main struts. In background is a Matchbox

F4U-4 for comparison.

|

CAMOUFLAGE & MARKINGS |

You’d have read this review about two months ago except for an unusually

miserable winter here on the US East Coast. The paint shop corner of my

basement has no heat, which isn’t a problem unless the outside temperature

gets below freezing and stays there a long time, which it did this year. If it

wasn’t too cold to paint, it was too humid, and most days this winter it was

both.

When Editor Scott sent me the kit for review, he said, “Don’t tell me how

you’re gonna paint it--surprise me.” The race #57 scheme is stunningly

beautiful, but looking at the one million tiny black pinstripe decals included

on the sheet for this scheme scared the hell out of me, and I knew that I’d

never get the model finished if I went this way with it.

Cleland’s all-white race #94 is attractive, but I didn’t like the extended

cowling scoop on it that much. That left Pucket’s stock-bodied #18 as the only

race option. I ultimately decided against it for two reasons: One, I don’t

have any other racers built in 1/72 (had the kit been in 1/48, I might have

built it this way), and, Two, at this point I had no idea how the kit decals

would behave.

I decided on the straight Navy option, figuring that if the kit decals

dissolved, crumbled, shattered, shrank, bled, or fell off, I could scrounge up

something from the spares box and press on.

I decided on the straight Navy option, figuring that if the kit decals

dissolved, crumbled, shattered, shrank, bled, or fell off, I could scrounge up

something from the spares box and press on.

Paint is overall Model Master Glossy Sea Blue, thinned with naphtha (lighter

fluid) for a glossier finish. (Cutting this stuff with my customary beloved

lacquer thinner gives a grainier, flatter finish). I am happy to report that

the kit decals were just beautiful--in register, opaque, thin, sturdy,

movable, etc. They were as good as any decals I’ve ever used from anybody, and

better than most of them. I wish all decals were this good. If you want to

build one of the racers, go for it--the decals won’t let you down.

What you see in the photos is the decals right over the paint--no gloss coat,

no sealers, no decals solvents or setting solutions. I did use Testor Decal

Set under the decals as a wetting agent to prevent air bubbles, but nothing on

top of them. Beautiful. I should also point out that in some of the pics it

looks like there’s a white border to the yellow numbers, as if the decals had

yellow printed over white, not quite in register. This is some kind of

photographic anomaly--no such white border appears on the model itself.

Similarly, the blue in the national insignia appears much lighter in the pics

than on the model itself. In reality, this blue is just barely lighter than

the GSB, not the baby blue in the pics. (It should be a shade darker

than the GSB.)

|

CONCLUSIONS |

I built this kit as close to OOB as I could stand, the major “fix” being the

wing root intakes. There are some other things I can fix later, as the mood

strikes me. For a more detailed and thorough look at building and correcting

the Xotic (formerly known as Aviation USK) F2G, I can highly recommend Joe

Hegedus’ cover story in the January 2000 FineScale Modeler magazine, and

Rodney Williams’ multipart feature article on F2Gs at

www.aircraftresourcecenter.com. Both these resources were of invaluable help

to me in this buildup.

May 2003

This was only my second limited-run kit, and compared to the first, it was a

joy to build. I can think of several “mainstream” kits that have given me more

trouble and less pleasure. The wing has issues, but they can be fixed. Missing

details such as the exhausts, pitot tube, and tailhook aren’t outside the

scratchbuilding abilities of the experienced modeler (or even many novices).

Although it seems pricey at first glance, the kit represents good value, and

if you want an F2G for your 1/72 collection, I can recommend the Xotic kit

highly.

Model on!

Thanks to Joe Hegedus for information and ideas, and to Scott Van Aken for

the opportunity to build and review the kit.

Copyright ModelingMadness.com. All rights reserved. No reproduction in part or in whole without express permission.

If you would like your product reviewed fairly and fairly quickly, please contact the editor or see other details in the Note to Contributors.