Hasegawa 1/48

Ki-61-I Hei Hien (Tony)

|

KIT #:

|

9087 (Jt87)

|

|

PRICE:

|

$26.95

|

|

DECALS:

|

Two options

|

|

REVIEWER:

|

Andrew Garcia

|

|

NOTES:

|

Eduard Zoom FE315

|

The

Ki-61 Hien “Tony” was the only mass produced fighter used by the Japanese during

WWII which used an inline engine. For

more a more detailed history of the Ki-61 series, see previous build articles in

the Modeling Madness Review Archives.

Hasegawa’s

announcement of a new mold 1/48 Ki-61 Hien (Tony) in late 2004 was eagerly

anticipated by Hasegawa WWII Japanese aircraft subject Fans.

Many folks wondered if it would improve

much over the nice Otaki/Arii kit. Yes, it is a clearly better kit and the

cockpit for example is the major improvement. Also, Hasegawa has correctly

addressed the two different Ki-61 fuselage lengths with dedicated moulds which

Otaki/Arii did not.

There

are about fourteen (14) Ki-61 releases from Hasegawa since the initial January

2005 release. I had thought the releases were just minor decal changes since the

Ki-61, with my limited knowledge, looked the same in all the photo references I

had. I wish for example Squadron Books In Action and other English language

modelers books would come out with some reference books on Japanese aviation

subjects. How about a Koku-Fan Famous Airplanes of the World No. 17 (7-1989)

Army Type 3 Fighter Hien English translation at a minimum?

While reading and browsing the web trying to understand the Ki-61

variants and their Hasegawa re-boxing I noticed Hasegawa released the two

different fuselage versions - a long fuselage version (8.94 meters long) and a

short fuselage (8.74 meters) version. Based on my limited knowledge, and since

it is not easy to read the Hasegawa box art description and confirm which

fuselage version I am getting in the box I stalled my building effort in order

to sort this one out. When you buy aftermarket decals they are not clear (to me)

which fuselage is appropriate. Sometimes the more you know the harder it is to

model.

There

are about fourteen (14) Ki-61 releases from Hasegawa since the initial January

2005 release. I had thought the releases were just minor decal changes since the

Ki-61, with my limited knowledge, looked the same in all the photo references I

had. I wish for example Squadron Books In Action and other English language

modelers books would come out with some reference books on Japanese aviation

subjects. How about a Koku-Fan Famous Airplanes of the World No. 17 (7-1989)

Army Type 3 Fighter Hien English translation at a minimum?

While reading and browsing the web trying to understand the Ki-61

variants and their Hasegawa re-boxing I noticed Hasegawa released the two

different fuselage versions - a long fuselage version (8.94 meters long) and a

short fuselage (8.74 meters) version. Based on my limited knowledge, and since

it is not easy to read the Hasegawa box art description and confirm which

fuselage version I am getting in the box I stalled my building effort in order

to sort this one out. When you buy aftermarket decals they are not clear (to me)

which fuselage is appropriate. Sometimes the more you know the harder it is to

model.

However, the

Modeling Madness, Tony Hodun Hasegawa kit tables, cracked the code. Look at the

fuselage parts table and you will see the two sizes using separately coded

sprues called out as the “longer” or “shorter” fuselage. This is a big problem

for builders who care about accuracy because I have not found aftermarket decal

makers explaining or mapping into this difference. For example, I have a nice

Superscale decal sheet, 48-511 which has a marking that I am not sure which

fuselage should be used to get the correct end result. The drawings are not

accurate; they are just for decal placement purposes. One of the versions is

found in the Hasegawa Kit # 9112 release, so maybe all three on 48-511 are for

the long fuselage version (?). You are now back to finding a picture of the

aircraft, hoping it is from the correct angle to permit a guess as to which

fuselage to use.

I

had also read a web thread about a 9.16 meter length for the Ki-61-I with its

Ha-140 engine which also had some outline changes to the canopy, tail, rudder,

etc but it is usually called out in references as the Ki-61-II and it is not

part of the Hasegawa releases so far – I think! Sometimes more knowledge is not

better and can lead to avoiding building something until you have better

information.

There

are wing armament variations as well within the fuselage lengths so be careful

when you build matching your decals to the correct fuselage. A few German MG-151

(20mm cannons) were imported from Germany via U-boat for testing in several

Japanese airplanes. They were evaluated and used after a brief study of its

technical details. The German-Italian-Japanese technology transfer contract was

called "Achse-Vertrag" in Germany. The armament changes can be seen in Japanese

magazines such as Model Art, and in Polish magazines (such as Miniature Lotniczy)

and on the box covers of Japanese short run resin kits in 1/48 scale from "The

Right Stuff" aka the "TC-Berg or Toy Craft Berg" company. They have produced a

resin Ki-61 HIEN in the "-Hei " and in the (lengthened nosed) "-Tei" model which

have been long out of production.

There

are wing armament variations as well within the fuselage lengths so be careful

when you build matching your decals to the correct fuselage. A few German MG-151

(20mm cannons) were imported from Germany via U-boat for testing in several

Japanese airplanes. They were evaluated and used after a brief study of its

technical details. The German-Italian-Japanese technology transfer contract was

called "Achse-Vertrag" in Germany. The armament changes can be seen in Japanese

magazines such as Model Art, and in Polish magazines (such as Miniature Lotniczy)

and on the box covers of Japanese short run resin kits in 1/48 scale from "The

Right Stuff" aka the "TC-Berg or Toy Craft Berg" company. They have produced a

resin Ki-61 HIEN in the "-Hei " and in the (lengthened nosed) "-Tei" model which

have been long out of production.

The

Ho-5 engine was installed in the "Tei" nose! The "-Tei" version (i.e. long

fuselage) only and always had the cannons in its fuselage. This is the reason

why its overall length was increased.

One

surprising flaw in the Hasegawa Ki-61 kit is the lack of intake grills for the

air intake. You need to add a scratch made grill which can be worked up from

stretched-sprue or Evergreen plastic strips to the engine air intakes –

Part A4. The intake is just an open square box whereas the actual aircraft has

four blades (see Model Art # 263 page 31 and

Model Art Profile Kawasaki

Ki61 Hien No. 733 page 80). The same part number is

used for the short and long fuselage versions in all the Hasegawa kits. Some

texts indicate a difference in size of the intakes such as one stating, “The air

intake was modified in outline and position because of the new engine design.

The engine cowl or cover has a rounder outline for better streamlining.” I have

not been able to conclusively affirm this is reflected in the two fuselage

variations moulded by Hasegawa. I always defer to Hasegawa because their

research is usually very reliable. Surprisingly, the easy fix for the missing

intake grill could have been found on the Eduard etched sets for the Ki-61 – but

so far Eduard missed this correction. I hope they address this in the future.

As

Scott and others have pointed out in the past the kit has a one piece cockpit

canopy. If you want to look inside, it is easier with an opened three piece

cockpit. Although I have the True Details vac-form which was originally issued

for the Otaki/Arii kit, it is easier to affix the plastic kit canopy, so I cut

it open the clear kit parts with a thin razor saw. It looks OK but not perfect.

The sit of the open canopy is not perfect for the sliding canopy portion, but it

works for me for this build. I don’t think it would pass muster with the contest

cops. The vac-form could help if this is a concern for you and you wish an open

canopy that properly sits on its canopy rail.

Part

A13, which is a small flap at the top of the landing gear, is very hard to

install since there is insufficient room at the top of the landing gear cover

(part C2/C3). This part comes on the Eduard etched set so you do have a nice but

hard to glue alternative with better scale thickness permitting a better look

than the plastic.

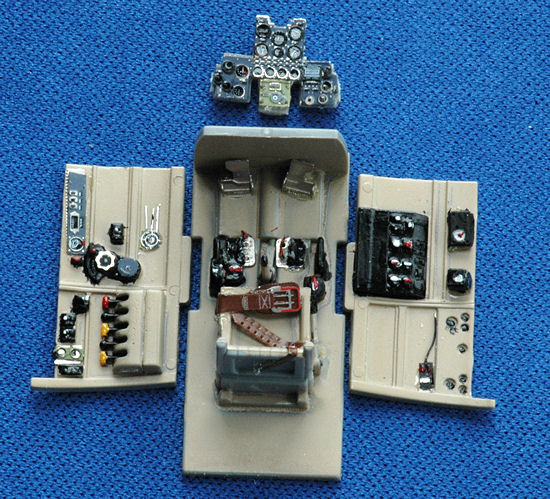

While

the kit instrument panel with the kit supplied decal looks nice, the Eduard Zoom

pre-painted etched panel looks much better. I was especially pleased with this

after the kit was completed. I built two Hasegawa Ki-61’s at the same time one

with Eduard and one without. Overall I feel it is one of the best components and

really enhanced the kit. I sparingly used gorilla glue to attach all the Eduard

instrument parts. Gorilla glue does expand and bubble up but it is very strong

improving on the occasional strength failure and tendency to wander and leave

vapor burns that plague using cyano glues. I am a big fan of using the Hasegawa

decal instrument panel with some setting solution like Microscale Sol but the

Eduard etched was definitely an improvement. The only trouble I usually have

with Eduard sets is attaching the small “T” handles.

While

the kit instrument panel with the kit supplied decal looks nice, the Eduard Zoom

pre-painted etched panel looks much better. I was especially pleased with this

after the kit was completed. I built two Hasegawa Ki-61’s at the same time one

with Eduard and one without. Overall I feel it is one of the best components and

really enhanced the kit. I sparingly used gorilla glue to attach all the Eduard

instrument parts. Gorilla glue does expand and bubble up but it is very strong

improving on the occasional strength failure and tendency to wander and leave

vapor burns that plague using cyano glues. I am a big fan of using the Hasegawa

decal instrument panel with some setting solution like Microscale Sol but the

Eduard etched was definitely an improvement. The only trouble I usually have

with Eduard sets is attaching the small “T” handles.

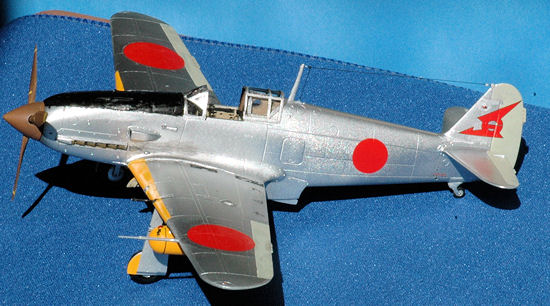

There

is a very bad transition from the fuselage parts to the lower wing parts which

is very visible at the trailing edge, of the bottom wing section. I thought this

was my failure to properly align the part on the first one I built. The same

thing occurred on the second build and since I was looking out for this in the

second build I think it is a mould or pattern maker mistake. Obviously the

bottom wing to fuselage join should not have the big step. The connection should

be aerodynamically smooth and it is not. I tried to smooth this out with putty

on the first build but it is a very large step and the end result was not good.

It should be part of the plastic. I love Hasegawa kits but this omission appears

in many of their kits – that is, the lower wing to fuselage join “just doesn’t”

on an otherwise flawless moulding.

I

found the kit rear landing wheel part to be very delicate. It broke on both my

builds (and on my Ki-44 too). I am a generally careful modeler so I would say it

takes some special care in handling so be forewarned.

The

small secondary landing gear doors (parts B2/B3) that have a brace (parts

A15/A16) which I found difficult to assemble. I can only say be careful with

this part of your assembly. I think the fit and contact of the parts could have

been better engineered for ease of assembly.

The

kit decals are nice but too glossy. However, I used Future Floor Wax as the

softening agent because they were the older, thicker Hasegawa decals. Although I

prefer to use the Microscale Sol/Set approach, I have found Future to work well

with older thick Hasegawa and Tamiya kit decals. I also use very hot water when

working with Hasegawa decals and they release faster and conform better with

this modeling tip. Future seems to help the decals adhere and snuggle down into

panel lines. This approach also introduces the potential for glossy decals when

you need flat coats. For aftermarket decals that are thin, the Microscale decal

setting agents work better permitting ease of placement. Since Future floor wax

is sticky and you may not be able to move decals after you apply them using

Future.

I

can’t say enough about the need to be sure of the model (variant) of the Ki-61

you are building because of the two

different fuselage lengths. They are not clearly called out by Hasegawa in the

box art or kit name. Possibly this is not a problem if you can read Japanese.

The changes are always noted in the aircraft assembly instructions introduction,

which is in the initial part of the kit assembly instructions, because the

length is given (8.94 meters “long” or 8.74 meters

“short”) but not really explained or

included

in the box art name.

included

in the box art name.

Another

easy way to see which version you have is to check the location of the exhaust

to the leading edge of the wing. You will notice the short version lining up

with the wing leading edge and the long version having a slight distance from

the end of the exhausts to the leading edge of the wing.

Also, you do have to look at

the related selection and position of the armament (both wing and fuselage!!!)

before you model one of them. But, until you have the exposed plastic part in

hand how do you know what’s in the box? Find out the fuselage tree codes using

the Modeling Madness charts! Now, if only the aftermarket decal types would

improve their recommendations with explicit Ki-61 fuselage type information, but

for now let’s get back to the build.

Overall

fit is very good, with a low parts count making for a simple assembly process.

Like all the new Hasegawa kits released in the past 15 years, surface detail is

refined and panel lines are perfectly scribed in a petit to scale manner giving

a terrific impression in the box and after the kit has been assembled.

The

cockpit plastic is very nice and there is no obvious need for a resin

replacement – especially when you use the kit supplied one-piece closed canopy.

If you do want to improve the cockpit area the first alternative I suggest is an

Eduard color etched Zoom (FE315) which does a lot and is a very nice addition. I

have the Aires resin cockpit (Aires #4017) and it looks very nice. I am saving

it for a future build once I get a definitive handle on the areas requiring care

during construction so I don’t waste my time and money by “putting lipstick on

the pig”. Not that this kit without aftermarket is a pig in any way, it is just

an endearing term used to describe enhancements to a kit build which has

assembly errors or faults that cannot not be overcome with some fancy

aftermarket add-on.

Because

I intend to build several examples of the Ki-61 I decided to build a set of

reference models with minimal aftermarket and enhancements. I built two kits,

one with the long fuselage and one short fuselage version and did not worry

about some mistakes hoping to avoid them on future builds. I was looking for

some discount priced kits so I kept an eye on eBay for some Ki-61’s. I had the

misfortune of dealing with an eBay seller who sells kits along with buyer beware

notices in the kit listing. After reading his explanation I went ahead and won

the auction (due to a lack of other bidders?!) only to find some major

components missing and some parts glued together that I wished he had not done

so poorly.

Yes,

it was a bad buy but the hassle and cost of a return prevented me from sending

it back. He won’t ever see any more business from me. After initially blasting

him on the seller evaluation, I spoke with him and took pity on his

circumstances since he claimed he was a disabled retiree in Florida. At that

time I was only aware and disappointed with the decals. They were useless

because he obviously stored them in a very hot and humid location ruining the

decals (they were glued to the box) and not disclosing this. After a chat he

gave me a small shipment credit. That was before I found there were missing

plastic parts, like one of the cockpit sidewalls, and I just wrote the guy off

any future eBay buys. I then put some scratch building to work to remediate the

loss. Caveat emptor.

Yes,

it was a bad buy but the hassle and cost of a return prevented me from sending

it back. He won’t ever see any more business from me. After initially blasting

him on the seller evaluation, I spoke with him and took pity on his

circumstances since he claimed he was a disabled retiree in Florida. At that

time I was only aware and disappointed with the decals. They were useless

because he obviously stored them in a very hot and humid location ruining the

decals (they were glued to the box) and not disclosing this. After a chat he

gave me a small shipment credit. That was before I found there were missing

plastic parts, like one of the cockpit sidewalls, and I just wrote the guy off

any future eBay buys. I then put some scratch building to work to remediate the

loss. Caveat emptor.

Back to the

build - with the small parts count it is a fast build. Just follow the

instructions. I did not add the intake grill to this kit (i.e. to part A4) but

did to the Hasegawa # 9112 version using stretched sprue. I was building kit #

9112 simultaneously and wanted to see if it was a notable change worth doing.

Again, I wish this grill was part of the Eduard etched parts instead of some

other etched components that I elected not to use. The Eduard instrument panel

was attached to the plastic kit panel after its plastic surface detail was

removed. I glued the Eduard parts using gorilla glue which requires a very small

quantity to be effective. This glues bubbles up so use it sparingly.

I found the

wing tanks to be a difficult attachment process unless done before painting the

wing. My recommended solution after building two of the Hasegawa Ki-61’s is if

you are going to attach the wing tanks to attach the rack using plastic glue

without the tank. I suggest painting the drop tank and attaching the tanks after

all other painting and finishing is complete.

The

cockpit of the Ki-61 is an unusual color. When I see one painted in zinc

chromate green or Japanese blue-green I now know it looks wrong. The perfect

cockpit color match is Gunze Aqueous H79 RLM Sandy Yellow/Dark Yellow semi-gloss

which I used. Although the new Mr. Color replacement paints, available in the

U.S. are solvent based, and are very nice, I really miss the aqueous line. I

found I could get perfect results with Aqueous, and using Simple Green (SG)

cleaner I could restore the airbrush parts to like new condition with water &

SG. I found Simple Green when used on Gunze Aqueous was a miracle cleaner

removing all pigment from air brushes, etc. Also, the thinner I used with Gunze

Aqueous, a hardware store Shellac thinner, which is essentially high-grade wood

alcohol, worked perfectly. This gave me a low cost and effective thinner for

Gunze Aqueous to provide more money for buying kits!

Getting the cockpit color right was another learning experience.

There are some color drawings of Ki-61 cockpits which appear to use zinc

chromate green, such as page 48 in the Osprey Duel # 26 book. Based on

Hasegawa’s instructions, Scott Van Aken’s

previous

Hasegawa Ki-61 build article, and Japanese language references confirming

Kawasaki’s paint colors the sandy yellow was used.

previous

Hasegawa Ki-61 build article, and Japanese language references confirming

Kawasaki’s paint colors the sandy yellow was used.

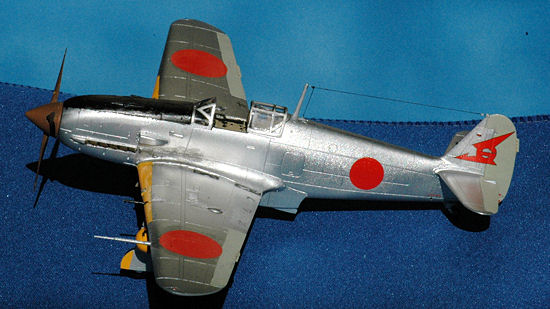

For

the overall fuselage finish I used Alclad Duraluminum and Polished Aluminum. It

was easy to use and the results good with a fast drying time and no masking

pull-up losses. I think with more NMF practice I can improve my use of Alclad. I

normally don’t prime my models, but I will in a future build to see first-hand

the changed metallic finish obtained when you use Alclad over an enamel base. As

Scott has indicated, a gloss black primer, is usually used with Alclad when you

want a high shine surface. I used Aves Apoxie sculpt to fill in any gaps such as

the wing to fuselage join but I try to use water and my wet finger tip for most

of the gap repairs when I use Apoxie to avoid sanding away surface details. It

is also faster and easier to dip your finger or a metal sculpting tool in water

and avoid sanding.

I used a brush

and two step process for painting the exhaust pipes. I brushed on Metalizer Dark

Iron non-buffing. When it was dry I used some thinned Pactra IP96 Rust enamel as

a wash.

Tamiya

acrylics in a yellow with a few drops of red added to the mixture were used for

the IFF yellow-orange wing edges. Tamiya flat black for the engine cowl and

XF-14 J.A. Grey for the movable wing and tail surfaces finished the other parts

colors.

Some clear

sewing thread was used for the antenna wires which were then painted flat black

and attached using gorilla glue.

The stencils

came from the kit decals as well. My Japanese friends might find some placed

upside down so if you find any like this sorry about that oversight.

Weathering and

Final Coat – none due to the NMF finish. I have tried using Future on some NMF

“coats” and the loss of NMF luster is not what I wanted. I have stopped this

practice on natural metal finishes for the most part unless I want or need a

flat aluminum finish. Although it helps hiding decal clear coats unless I want a

very flat finish I usually don’t apply any top coat to a NMF paint.

Aside from the

engine area, I did minimal weathering of the airframe keeping it to using Tamiya

chalk and weathering sets. I did not spray on a gloss coat to seal in all the

decals instead using the Future coat used during the initial application to seal

all of the decals.

I try to set

the kit aside for a day or two then come back with a critical “contest eye”.

This is a fast part for me. I always write up a “finishing steps notes” which is

a written document to help complete the final construction. I also keep this

handy since while fishing the kit I sometimes see or notice so mething

overlooked during the final steps. After making some mistakes in the past I now

keep this document handy for some handwritten additions that I spot while

working the final steps. I list the final detail colors and under each color

linked to the specific part with its painting and assembly step. For example,

under “silver” I noted “add a landing light using a round bead and paint the

bead silver. After gluing, paint on its tip a small gloss white dot.” For Flat

Black the final steps are touch ups to: Tires – main and rear, gunsight, landing

gear oleo rubber boots, antennae wire, anti-glare panel, and drop tank plumbing

pipes.

mething

overlooked during the final steps. After making some mistakes in the past I now

keep this document handy for some handwritten additions that I spot while

working the final steps. I list the final detail colors and under each color

linked to the specific part with its painting and assembly step. For example,

under “silver” I noted “add a landing light using a round bead and paint the

bead silver. After gluing, paint on its tip a small gloss white dot.” For Flat

Black the final steps are touch ups to: Tires – main and rear, gunsight, landing

gear oleo rubber boots, antennae wire, anti-glare panel, and drop tank plumbing

pipes.

Final construction is usually paint

touch-up oriented so I get the flat black items all at one stroke rather than

doing it in multiple steps. Although I did not do it here I will in future

builds of the Ki-61 Hien kit attach the drop tanks in the final steps. The clear

parts including the landing gear light cover on the wing were added using

Testors 8876C white glue. I use this because of its long, tapered black plastic

applicator that allows small amounts of glue to be carefully placed. The radio

mast and antennae wire was attached and painted as the last step.

I really

enjoyed building the Hasegawa Tony. It is definitely better than the older

alternatives. By coming up with the thought that this was a “reference build”, I

could overlook some flaws and keep pushing to completion and avoid another

almost finished shelf of doom kit. I found I enjoyed the kit much more and

obtained more relaxation and enjoyment avoiding the shelf of doom status for the

kit as some errors like breaking off the fuselage antenna, drop tanks, rear

landing gear (a very delicate and weak part by the way) could have stopped final

completion of a most enjoyable kit.

Model Art No. 263 Ki-61 Hien Army Type 3 Fighter

Kawasaki Ki-61 Hien by Richard M. Bueschel, Schiffer Books 1996

P-38

Lightning vs Ki-61 Tony New Guinea 1943-44 by Donald Nijboer, Osprey Duel Series

# 26

The Maru Mechanic No. 45

1984/3 Ki-43 and Ki-61

Model Art Profile Kawasaki

Ki61 Hien No. 733

Andrew Garcia

November 2012

If you would like your product reviewed fairly and fairly quickly, please

contact

the editor or see other details in the

Note to

Contributors.

Back to the Main Page

Back to the Review

Index Page

Yes,

it was a bad buy but the hassle and cost of a return prevented me from sending

it back. He won’t ever see any more business from me. After initially blasting

him on the seller evaluation, I spoke with him and took pity on his

circumstances since he claimed he was a disabled retiree in Florida. At that

time I was only aware and disappointed with the decals. They were useless

because he obviously stored them in a very hot and humid location ruining the

decals (they were glued to the box) and not disclosing this. After a chat he

gave me a small shipment credit. That was before I found there were missing

plastic parts, like one of the cockpit sidewalls, and I just wrote the guy off

any future eBay buys. I then put some scratch building to work to remediate the

loss. Caveat emptor.

mething

overlooked during the final steps. After making some mistakes in the past I now

keep this document handy for some handwritten additions that I spot while

working the final steps. I list the final detail colors and under each color

linked to the specific part with its painting and assembly step. For example,

under “silver” I noted “add a landing light using a round bead and paint the

bead silver. After gluing, paint on its tip a small gloss white dot.” For Flat

Black the final steps are touch ups to: Tires – main and rear, gunsight, landing

gear oleo rubber boots, antennae wire, anti-glare panel, and drop tank plumbing

pipes.