HiPM 1/48 Bv-141B

|

KIT # |

48004 |

|

PRICE: |

AU $61.00 |

|

DECALS: |

Two Options |

|

REVIEWER: |

Ewart Yong |

|

NOTES: |

Short run kit. Aires accessories used |

|

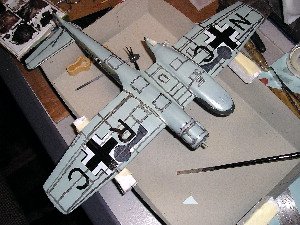

HISTORY |

The BV-141B has to be one of the strangest looking aircraft to appear during WWII; it was designed in 1937 by Richard Vogt. It was a private venture in response to a specification issued by the RLM for a light reconnaissance and bombing aircraft for army cooperation duties. Earlier variants spotted a more conventional tail plane. This was modified to the asymmetric configuration of the B variant to improve the rear gunner’s field of fire. Unfortunately, this modification adversely affected the reportedly good handling characteristics of the prototype. At that time, the other competitor for the RLM’s specification of a light reconnaissance aircraft was the FW-189, a twin-engined /boomed aircraft of more conventional design. Eventually, the latter became operational while the BV-141 only served in evaluation squadrons and never saw any widespread operational service. The BV-141’s disfigured appearance coupled with official skepticism of such an unorthodox aircraft ensured that the design never reached full operational status and hastened the inevitable demise of this program.

|

THE KIT |

I purchased this kit while

on vacation to Adelaide in 2001. It was the only one left on the shelves

amongst other HiPM kits. I have always wanted to build a model of this

aircraft and the only offerings till then were in 1/72nd scale

by Airfix and Bilek. Since I primarily build in 1/48th scale, I

bought this kit immediately. The esoteric nature and the asymmetrically

ugly lines of this beast endeared me to the subject almost immediately.

I purchased this kit while

on vacation to Adelaide in 2001. It was the only one left on the shelves

amongst other HiPM kits. I have always wanted to build a model of this

aircraft and the only offerings till then were in 1/72nd scale

by Airfix and Bilek. Since I primarily build in 1/48th scale, I

bought this kit immediately. The esoteric nature and the asymmetrically

ugly lines of this beast endeared me to the subject almost immediately.

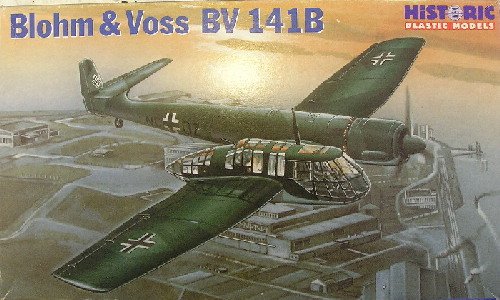

The kit comes in a moderately sturdy top-opening box adorned with a not too great box art. Side flaps show photographs of the completed model and the clear molded bits and photo etched parts. What struck me upon opening the box was the size of the model, the fuselage boom almost filled up the entire length of the box and the box itself was cramped full of sprues.

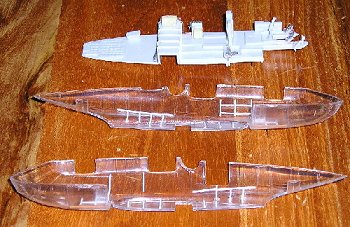

The kit is molded in a light gray hard plastic. An unusual feature of this kit is the gondola, which is molded entirely in clear plastic. The advantage of this is that there will not be any tricky placements of windows to worry about. Unfortunately, the joint line runs across two window panels. Unless these window panels are replaced, it would be impossible to eliminate this visible joint line.

Also provided is a fret of stainless steel photo-etched parts containing the instrument panel and other cockpit details, the machine gun ports for the fixed forward firing guns, the gunsight for these, optional etched torque links for the undercarriage, seat belts and the cooling fan for the engine.

The instruction sheet consists of a brief written history of this aircraft in English, a map showing the parts layout, a reasonably clear and logical step by step construction sequence and painting and decal placement guide. RLM coding is used to reference the major colours; no specific brand of paints are quoted. I personally like this since it eliminates ambiguities associated with generic descriptions like ‘dark green’ or ‘Humbrol 78’.

Two options are provided

on the decal sheet. The decals are printed by Propagteam and opacity

looked excellent on initial inspection. Registration is a tad off and

especially noticeable on the swastikas. The latter as is common practice

these days is printed in two parts to allow the kit to be sold in the EU.

I found this strange, since the box art shows the full swastika. I had my

reservations about the decals since I have read reviews about Propagteam

decals being extremely thin and unforgiving once they are put in place,

being prone to tearing when trying to position them on the model.

Two options are provided

on the decal sheet. The decals are printed by Propagteam and opacity

looked excellent on initial inspection. Registration is a tad off and

especially noticeable on the swastikas. The latter as is common practice

these days is printed in two parts to allow the kit to be sold in the EU.

I found this strange, since the box art shows the full swastika. I had my

reservations about the decals since I have read reviews about Propagteam

decals being extremely thin and unforgiving once they are put in place,

being prone to tearing when trying to position them on the model.

A preview of this kit done by Matt Swan indicates that moldings in his example were excellent. Regrettably, this was not the case with mine. There was quite a lot of flash on the parts which needed tedious cleaning up. Numerous sink holes marred the side consoles and spare ammunition drums in my kit. Also, the transparent gondola exhibited several imperfections which necessitated tedious clean up and polishing at a latter stage.

The undercarriage oleos had lots of thick flash and the cross section was out-of-round. These are best scratch-built with brass tubing (like I did). The two MG-15 flexible machine guns were represented by shapeless blobs of plastic with lots of flash, rendering them totally unusable. These are best replaced with after-market accessories. Panel lines are recessed and quite crisply molded. Like most short-run kits, no locating pins or tabs are provided. Also the wing root joints to the engine boom and gondola are butt-jointed and it is recommended that strengthening spars fashioned from 40 thou plastic sheet be incorporated for reinforcement. This is a rather large and heavy model and the wing root joints will definitely crack if handled without any form of reinforcement in the wings.

This certainly is no shake ‘n’ bake kit….

|

CONSTRUCTION |

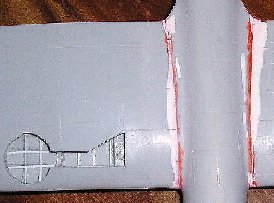

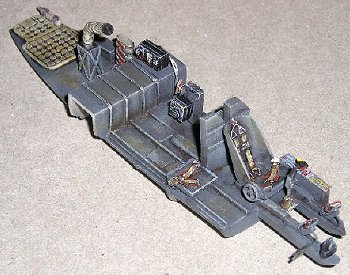

THE MAIN AIRFRAME: I

departed from the assembly sequence stated in the instructions and

assembled the fuselage boom, wings and tail plane as a complete

sub-assembly. Before assembling the wing halves, plastic strips were added

to depict framing detail in the wheel bays. A stiffening spar corresponding to the contours

of the portion where the gondola fitted was fashioned out of 40 thou

plastic card to extend right through to the wing section where the gondola

meets the fuselage boom on the port wing and up to the straight portion of

the starboard wing. The stiffening spar also served to ensure correct

alignment of the two wing sections just outboard of the gondola. If assemble

THE MAIN AIRFRAME: I

departed from the assembly sequence stated in the instructions and

assembled the fuselage boom, wings and tail plane as a complete

sub-assembly. Before assembling the wing halves, plastic strips were added

to depict framing detail in the wheel bays. A stiffening spar corresponding to the contours

of the portion where the gondola fitted was fashioned out of 40 thou

plastic card to extend right through to the wing section where the gondola

meets the fuselage boom on the port wing and up to the straight portion of

the starboard wing. The stiffening spar also served to ensure correct

alignment of the two wing sections just outboard of the gondola. If assemble d per the

instructions, there would be a noticeable droop. This spar was glued

securely with generous applications of super glue and accelerator. The

bottom outboard panel of the starboard wing was a separate piece and the

attachment to the gondola section was reinforced with strips of plastic

sheets to ensure a strong joint. The port wing was straightforward, just

the top and lower halves which were glued together as usual. The port wing

was then attached to the fuselage boom, reinforced with brass tubing at the

leading and trailing edges through the boom and a generous application of

super glue at the roots. The two locating lugs on the lower half of the

tail plane were removed; if this was fitted on to the locating holes of

the vertical fin slot, the elevator hinge line will not be perpendicular to

the fuselage boom and would result in a pronounced back sweep; my

references indicate that this was not the case. The supporting strut was

fitted and the whole assembly left aside to dry. The wing root joints were

a poor fit to the fuselage boom and Milliput epoxy putty was used to smooth

this joint. At this juncture, all joints were sanded smooth and panel

lines lost in the process were restored with my scriber. I proceeded with

the engine cowl assembly. This was a tricky affair as the cowl was molded

in two halves. No engine is provided but this is of no concern

d per the

instructions, there would be a noticeable droop. This spar was glued

securely with generous applications of super glue and accelerator. The

bottom outboard panel of the starboard wing was a separate piece and the

attachment to the gondola section was reinforced with strips of plastic

sheets to ensure a strong joint. The port wing was straightforward, just

the top and lower halves which were glued together as usual. The port wing

was then attached to the fuselage boom, reinforced with brass tubing at the

leading and trailing edges through the boom and a generous application of

super glue at the roots. The two locating lugs on the lower half of the

tail plane were removed; if this was fitted on to the locating holes of

the vertical fin slot, the elevator hinge line will not be perpendicular to

the fuselage boom and would result in a pronounced back sweep; my

references indicate that this was not the case. The supporting strut was

fitted and the whole assembly left aside to dry. The wing root joints were

a poor fit to the fuselage boom and Milliput epoxy putty was used to smooth

this joint. At this juncture, all joints were sanded smooth and panel

lines lost in the process were restored with my scriber. I proceeded with

the engine cowl assembly. This was a tricky affair as the cowl was molded

in two halves. No engine is provided but this is of no concern

since most

of the cowl opening is hidden by the large cooling fan. The cooling fan is

provided as a photo-etched part that required careful twisting to obtain

the correct pitch. This is quite a tight fit in the cowl opening and

further adjustments and bending were needed to ensure a snug fit. The

exhaust manifold was poorly molded with lots of flash, requiring tedious

cleaning up to ensure a passable fit. The more fastidious among you might

choose to replace these with hollow tubing instead. My reference photos

also indicate that the rudder hinges were of the semi-circular variety and

not the shapeless bumps depicted in the kit. These were removed and the

hinges rebuilt with plastic sheet to match the photos of my references.

since most

of the cowl opening is hidden by the large cooling fan. The cooling fan is

provided as a photo-etched part that required careful twisting to obtain

the correct pitch. This is quite a tight fit in the cowl opening and

further adjustments and bending were needed to ensure a snug fit. The

exhaust manifold was poorly molded with lots of flash, requiring tedious

cleaning up to ensure a passable fit. The more fastidious among you might

choose to replace these with hollow tubing instead. My reference photos

also indicate that the rudder hinges were of the semi-circular variety and

not the shapeless bumps depicted in the kit. These were removed and the

hinges rebuilt with plastic sheet to match the photos of my references.

COCKPIT: The main

components of the cockpit were assembled as specified in the instructions.

At this point, I also cut away the portion of the rear cockpit floor just

under the wing spar box to accommodate the stiffening spar added in the

airframe. The pilot’s seat

had lots of flash and molding imperfections which had to be tediously

cleaned up. I considered rebuilding the seat out of plastic sheet but

decided against the idea since the ample seatbelts would hide most of the

imperfections. The trim wheel was fashioned out of copper wire and super

glued to the right side of the seat. Other enhancements to the cockpit

include addition of wiring, throttle quadrant and levers, radios added from

Aeries Luftwaffe radio sets (these are spurious according to my references,

I only got some good references from the web after I finished the cockpit)

and ribbing detail added to the wing spar box (again, these are spurious –

my references indicate a plain structure devoid of any detail). The

cockpit assembly was painted RLM 66 and a black water colour wash was

subsequently applied to accentuate details. The assembly was dry brushed

with neutral gray before other details such as the etched seat belts and

rear gunner’s padding were painted. The cockpit was then dusted with brown

pastel chalk dust to simulate dirt and grime before the whole assembly was

sprayed with Dullcote

COCKPIT: The main

components of the cockpit were assembled as specified in the instructions.

At this point, I also cut away the portion of the rear cockpit floor just

under the wing spar box to accommodate the stiffening spar added in the

airframe. The pilot’s seat

had lots of flash and molding imperfections which had to be tediously

cleaned up. I considered rebuilding the seat out of plastic sheet but

decided against the idea since the ample seatbelts would hide most of the

imperfections. The trim wheel was fashioned out of copper wire and super

glued to the right side of the seat. Other enhancements to the cockpit

include addition of wiring, throttle quadrant and levers, radios added from

Aeries Luftwaffe radio sets (these are spurious according to my references,

I only got some good references from the web after I finished the cockpit)

and ribbing detail added to the wing spar box (again, these are spurious –

my references indicate a plain structure devoid of any detail). The

cockpit assembly was painted RLM 66 and a black water colour wash was

subsequently applied to accentuate details. The assembly was dry brushed

with neutral gray before other details such as the etched seat belts and

rear gunner’s padding were painted. The cockpit was then dusted with brown

pastel chalk dust to simulate dirt and grime before the whole assembly was

sprayed with Dullcote  lacquer from a spray can to seal everything in . The instrument panel

assembly consisted of an etched panel with acetate sheet depicting the

instrument dials. The acetate sheet was to be sandwiched between the

photo-etched panel and injection-molded backing supplied with the other

plastic parts. The latter was discarded and replaced with plastic sheet.

Details such as the individual instrument housings and wiring were added to

the rear of the panel from sections of plastic rod and fine gauge copper

wire respectively. The entire subassembly was painted and details picked

out with a fine 00 brush.

lacquer from a spray can to seal everything in . The instrument panel

assembly consisted of an etched panel with acetate sheet depicting the

instrument dials. The acetate sheet was to be sandwiched between the

photo-etched panel and injection-molded backing supplied with the other

plastic parts. The latter was discarded and replaced with plastic sheet.

Details such as the individual instrument housings and wiring were added to

the rear of the panel from sections of plastic rod and fine gauge copper

wire respectively. The entire subassembly was painted and details picked

out with a fine 00 brush.

GONDOLA: As mentioned,

the transparent moldings representing the gondola had numerous

imperfections. These were wet sanded, both inside and outside with 1200

grit abrasive paper and polished with Novus 2 and 3 plastic polish. This

was a tedious process which took several evenings due to the multitude of

molding imperfections. The inside was then brushed with several coats of

Future floor polish, allowing at least two hours between coats. Even so,

the resultant finish was less than satisfactory but a vast improvement over

the original molding. With this done, I cut out a portion where the wings

fitted, corresponding to the stiffening spar added earlier. Frame details

were added from 25 thou square strips with super glue. The appropriate

window panels were masked off from the inside and sprayed with RLM 66 and

given the same treatment as the cockpit assembly to highlight and weather

the interior. At this point, the map cases, spare ammo drums and

instrument panel were fitted with superglue. Caution must

be exercised

with the instrument panel, no locating pins or equivalent are provided and

any slip may mar one of the top window panels. Once done the photo etched

ring sight was added to the underside of the instrument panel. Location

for this was vague in the instructions and I used an educated guess in

conjunction with photos of a completed model of the FW-189 to obtain the

final position. The gun mounting rings were also added at this juncture.

Attaching the ring for the top rearward-firing gun is tricky; the opening

in the gondola halves for this need to be enlarged. Also, do not make the

same mistake as I did; the gun should be offset to the left when looking

from the rear of the gondola and not centered (like I did mine). The

excellent resin Aeries MG-15’s were added to the gun-mounting rings less

the barrels to avoid handling damage during subsequent painting and

assembly. The cockpit floor was then test fitted to the port half of the

gondola. This revealed that the cartridge collection chute for the top gun

was slightly too long. This was trimmed down until a satisfactory fit was

obtained. Once I was satisfied, the cockpit floor was super-glued to the

port half of the gondola and the two halves joined with liquid cement. With the glue fully set,

I went about the arduous task of sanding

be exercised

with the instrument panel, no locating pins or equivalent are provided and

any slip may mar one of the top window panels. Once done the photo etched

ring sight was added to the underside of the instrument panel. Location

for this was vague in the instructions and I used an educated guess in

conjunction with photos of a completed model of the FW-189 to obtain the

final position. The gun mounting rings were also added at this juncture.

Attaching the ring for the top rearward-firing gun is tricky; the opening

in the gondola halves for this need to be enlarged. Also, do not make the

same mistake as I did; the gun should be offset to the left when looking

from the rear of the gondola and not centered (like I did mine). The

excellent resin Aeries MG-15’s were added to the gun-mounting rings less

the barrels to avoid handling damage during subsequent painting and

assembly. The cockpit floor was then test fitted to the port half of the

gondola. This revealed that the cartridge collection chute for the top gun

was slightly too long. This was trimmed down until a satisfactory fit was

obtained. Once I was satisfied, the cockpit floor was super-glued to the

port half of the gondola and the two halves joined with liquid cement. With the glue fully set,

I went about the arduous task of sanding

and polishing the joints. Once

done, I proceeded with the tedious job of masking all the windows. I used

Scotch frosted tape and a cutter for this purpose. This process drove me

almost blind and to the verge of insanity.

and polishing the joints. Once

done, I proceeded with the tedious job of masking all the windows. I used

Scotch frosted tape and a cutter for this purpose. This process drove me

almost blind and to the verge of insanity.

When satisfied, I proceeded with test fitting the gondola assembly to the main airframe. This is when I discovered more fit problems. The gondola was about 2 millimetres too wide to fit the opening and the wing root profile was thicker than the wings themselves. I proceeded to sand down the gondola at the wing root area with 150 grit abrasive paper to reduce the width, test fitting frequently along the way. I then attached the gondola to the wings with super glue and reinforced all joints with further application of glue and accelerator. Another anomaly was that the underside of the wings where the gondola sat was slightly too high. I proceeded to fill the wing root joints and smooth the lower portion with generous applications of plastic putty. These were wet sanded and once again, lost panel lines were restored as necessary with a scriber.

Next, I added the photo

etched gun ports to the front of the gondola and d rilled

out holes for the fixed forward firing gun barrels. The latter were

simulated with hypodermic syringe needles of the appropriate lengths.

rilled

out holes for the fixed forward firing gun barrels. The latter were

simulated with hypodermic syringe needles of the appropriate lengths.

UNDERCARRIAGE: The kit parts were out of round and suffered badly from flash. Only the wheel yokes were retained from the original kit part; the main oleos were rebuilt from brass tubing of the appropriate diameter. The canvas covers on the sliding members were simulated with putty, with the creases added using a toothpick. Brake lines and harnesses were added from copper wire and lead foil respectively (this was conjectural). I chose to use the plastic torque links rather than the photo-etched ones as the latter were too thin and did not depict this component realistically. The main undercarriage was then painted, weathered and set aside. The hole in the tail wheel where the yoke fitted was off center, this was filled with plastic rod and the hole re-drilled. The wheel was then fitted to the strut, painted and set aside for final assembly.

|

CAMOUFLAGE & MARKINGS |

Prior to painting preparation, I filed a semi-circular opening on the port wing leading edge for the landing light. A piece of transparent sprue was fitted to this opening, filed and polished. Wing tip lights were added from small pieces of plastic rod shaped appropriately. I did not use clear plastic for these as I felt they were small and needed only painting to look satisfactory. The pitot tube was replaced with brass tubing and a hypodermic needle of appropriate diameters and super-glued to the wing leading edge.

Usually at this stage, I

will wash the entire model with liquid dish washing solution. However, I

elected to depart from this usual practice for this model as I feared the

dishwashing solution might have an adverse effect on the Future polish in

the gondola. Instead, I wiped the entire model down with naptha (Zippo

lighter fluid) to remove any traces of grease, followed by a final rub

down with isopropyl alcohol. I masked off the wheel well openings with

tissue paper and the landing light with frosted tape and filled out the

various cockpit hatches with expanded polystyrene foam. I sprayed Testors

RLM 66 on the gondola

Usually at this stage, I

will wash the entire model with liquid dish washing solution. However, I

elected to depart from this usual practice for this model as I feared the

dishwashing solution might have an adverse effect on the Future polish in

the gondola. Instead, I wiped the entire model down with naptha (Zippo

lighter fluid) to remove any traces of grease, followed by a final rub

down with isopropyl alcohol. I masked off the wheel well openings with

tissue paper and the landing light with frosted tape and filled out the

various cockpit hatches with expanded polystyrene foam. I sprayed Testors

RLM 66 on the gondola area

as I wanted this colour to show through as the internal portion of the

framing. After the paint had dried for a day, I primed the entire model

with Humbrol Neutral Gray.

The assembly was then examined for any imperfections and these were fixed

before I proceeded to the next stage. At this point, I decided to add the

aerial mast after first reinforcing it with 12 thou guitar string. After

super gluing it to the gondola, I discovered another mistake. The aerial

mast should have been offset slightly to the port side instead of mounted

centrally. I decided to live with this mistake and proceeded on. I

pre-shaded all the panel lines with black paint sprayed through my Testors

airbrush. Once done, I

sprayed the lower surfaces with Testors RLM 65 enamel, using only two thin

coats so that the pre-shading could be visible through the final coat.

When the

area

as I wanted this colour to show through as the internal portion of the

framing. After the paint had dried for a day, I primed the entire model

with Humbrol Neutral Gray.

The assembly was then examined for any imperfections and these were fixed

before I proceeded to the next stage. At this point, I decided to add the

aerial mast after first reinforcing it with 12 thou guitar string. After

super gluing it to the gondola, I discovered another mistake. The aerial

mast should have been offset slightly to the port side instead of mounted

centrally. I decided to live with this mistake and proceeded on. I

pre-shaded all the panel lines with black paint sprayed through my Testors

airbrush. Once done, I

sprayed the lower surfaces with Testors RLM 65 enamel, using only two thin

coats so that the pre-shading could be visible through the final coat.

When the  paint had set for two days, I masked off the undersides with

Tamiya masking tape and paper. RLM 71 was sprayed on the top surfaces in a

similar manner to allow the pre-shading to be visible. When the paint had

dried for a day, I masked the splinter pattern once again with Tamiya

masking tape. Black paint was sprayed as pre-shading over the panel lines

once again before RLM 70 was applied to the unmasked area. Once this final

colour had dried to the touch, I removed all masking save for those on the

paint had set for two days, I masked off the undersides with

Tamiya masking tape and paper. RLM 71 was sprayed on the top surfaces in a

similar manner to allow the pre-shading to be visible. When the paint had

dried for a day, I masked the splinter pattern once again with Tamiya

masking tape. Black paint was sprayed as pre-shading over the panel lines

once again before RLM 70 was applied to the unmasked area. Once this final

colour had dried to the touch, I removed all masking save for those on the

canopy. The entire

assembly was set aside and allowed to cure thoroughly for two days before

subsequent handling. Any imperfections and over-spray were touched up

using the main camouflage colours shot selectively at the offending areas

using the finest setting of my airbrush.

canopy. The entire

assembly was set aside and allowed to cure thoroughly for two days before

subsequent handling. Any imperfections and over-spray were touched up

using the main camouflage colours shot selectively at the offending areas

using the finest setting of my airbrush.

Paint fading was simulated by carefully spraying thinned down light grey on selected panels. Paint chipping was then simulated using aluminium enamels carefully applied with a 00 brush on selected areas. Once done, the model was airbrushed with several coats of Testors Glosscote and allowed to dry for a further two days.

Decals were then applied

and thankfully, I experienced none of the problems reportedly associated

with Propagteam  decals. These reacted very well with Aeromaster Set and

Sol decal solutions. One point of caution however is that the under wing

crosses are labeled reversed in the instruction sheet. Once the decals

have been applied and allowed to dry for a further two days, the entire

model was cleaned with Jiff kitchen cleaner and a damp cloth to remove all

traces of decal residue. Panel lines were accentuated with a diluted

black-brown water colour wash

and any excess removed with a soft cloth moistened lightly with

kitchen cleaner.

decals. These reacted very well with Aeromaster Set and

Sol decal solutions. One point of caution however is that the under wing

crosses are labeled reversed in the instruction sheet. Once the decals

have been applied and allowed to dry for a further two days, the entire

model was cleaned with Jiff kitchen cleaner and a damp cloth to remove all

traces of decal residue. Panel lines were accentuated with a diluted

black-brown water colour wash

and any excess removed with a soft cloth moistened lightly with

kitchen cleaner.

At this point, the main undercarriage legs and tail wheel subassemblies were attached to the model with generous amounts of super glue for added strength. The model was set belly-up to allow the super glue fumes to escape without marring the finish. Once the glue had set (about 3 hours), the model was given two coats of Testors Dullcote with an airbrush.

Further weathering was simulated with pastel chalk. Dark brown pastel chalk powder was applied along selected panel lines and also used to simulate exhaust staining. Light grey pastels were applied in the middle of panels to reproduce paint fading. Surprisingly, although the BV-141 never saw operational service, my reference photographs show that this aircraft was quite severely weathered.

A further two coats of Dullcote varnish sealed everything in.

|

FINAL CONSTRUCTION |

The canopy masking was

then removed and the various window hatches were glued in the open

position. Hinges and latches for these were added from lead foil and fuse

wire and then painted as appropriate.

The canopy masking was

then removed and the various window hatches were glued in the open

position. Hinges and latches for these were added from lead foil and fuse

wire and then painted as appropriate.

The wing tip lights were first painted Humbrol silver and when dry were over painted with Tamiya Clear Red and Green.

The final touch was adding and painting the gun barrels and the photo etched ring and bead sights. The resin barrels were slightly bent, so these were immersed in boiling water and held straight while cooling.

All my references did not seem to indicate the presence of an aerial wire so these were not installed.

This model was finally finished on Christmas day, 2003. Whew!

|

CONCLUSIONS |

This kit represents an

esoteric subject which is a must for any fan of aviation’s oddities. It

fills an important gap in the 1:48th scale range of Luftwaffe

subjects. However, the difficult build exacerbated by the poor molding

with excessive flash and soft details mean that I can only recommend this

kit to the advanced modeler. To date I only know of two modelers who have

completed this kit;

Lukasz Kedzierski whose excellent work appeared in Hyperscale’s website in

2001 and the anonymous modeler whose work appears as the box side

photograph of the completed model. Despite the obscure nature of this

subject, I found a surprising number of websites with excellent detail

photographs of the actual prototype devoted to this subject.

Unfortunately, it only occurred to me to check these out after I had

completed assembly of the major components, hence the spurious nature of

the cockpit details, the orientation error of the upper rearward firing gun

and the misplaced aerial mast amongst other things. My experience with the

quality of this kit’s molding seems to be contradictory to Matt Swan’s

preview elsewhere in this site. Evidently, I must have acquired a lemon.

Will I build another HiPM kit? Probably the Pe-2 or FW-56 Stosser but not

for a long time … at least until I have regained my eyesight and sanity.

This kit represents an

esoteric subject which is a must for any fan of aviation’s oddities. It

fills an important gap in the 1:48th scale range of Luftwaffe

subjects. However, the difficult build exacerbated by the poor molding

with excessive flash and soft details mean that I can only recommend this

kit to the advanced modeler. To date I only know of two modelers who have

completed this kit;

Lukasz Kedzierski whose excellent work appeared in Hyperscale’s website in

2001 and the anonymous modeler whose work appears as the box side

photograph of the completed model. Despite the obscure nature of this

subject, I found a surprising number of websites with excellent detail

photographs of the actual prototype devoted to this subject.

Unfortunately, it only occurred to me to check these out after I had

completed assembly of the major components, hence the spurious nature of

the cockpit details, the orientation error of the upper rearward firing gun

and the misplaced aerial mast amongst other things. My experience with the

quality of this kit’s molding seems to be contradictory to Matt Swan’s

preview elsewhere in this site. Evidently, I must have acquired a lemon.

Will I build another HiPM kit? Probably the Pe-2 or FW-56 Stosser but not

for a long time … at least until I have regained my eyesight and sanity.

Kit courtesy of my over-used credit card.

|

REFERENCES |

Yenne, Bill; The World’s Worst Aircraft

Donald, David (editor); Warplanes of the Luftwaffe

January 2004

If you would like your product reviewed fairly and fairly quickly, please contact the editor or see other details in the Note to Contributors.