| KIT #: | 112 |

| PRICE: | $15.00 long out of production |

| DECALS: | One option |

| REVIEWER: | Mark Hiott |

| NOTES: | Ex Artiplast kit |

| HISTORY |

The Macchi

Castoldi MC 72 was an

experimental seaplane designed and built by the Italian aircraft company Macchi

Aeronautica. The M.C. 72 held the world speed record for all aircraft for five

years. In 1934, it set a world record speed for internal combustion powered

seaplanes which still stands to this day. The M.C. 72 design was unique with a

fuselage partly metal to the cockpit and wood monocoque bolted to the front

tubular portion by four bolts. The streamlined nose contours enclosed an oil

tank with its outside wall exposed to the airstream. The wing was all metal with

flat tubular water radiators smoothly faired into the wings. The twin pontoons

had three smoothly-faired radiators on the outer surfaces, the forward radiator

for water and the centre and rear radiators for oil cooling. The float struts

also featured

water

radiators and another radiator was fitted during hot conditions under the

fuselage running from cockpit to tail.

water

radiators and another radiator was fitted during hot conditions under the

fuselage running from cockpit to tail.

The M.C. 72

was built in 1931 with the idea of competing for what turned out to be the final

Schneider Trophy race, but due to engine problems, the M.C. 72 was unable to

compete. For two years, the M.C. 72 suffered from many mechanical defects, as

well as the loss of two test pilots who died trying to coax world class speed

out of the M.C. 72 (first Monti and then Bellini). The final design of M.C. 72

used double, contra-rotating propellers powered by a modified FIAT AS-6 engine

V24 engine generating some 1,900-2,300 kW (2,500-3,100 hp) thanks to

supercharging.

After 35

flights, the engines were overhauled in preparation for a record attempt. The

aircraft finally lived up to expectations when it set a new world speed record

(over water) on 10 April 1933, with a speed of 682 km/h (424 mph). It was

piloted by Warrant Officer Francesco Agello (the last qualified test pilot). Not

satisfied, development continued as the aircraft's designers thought they could

break 700 km/h (430 mph) with the M.C. 72. This feat was in fact achieved on 23

October 1934, when Agello piloted the M.C. 72 for an average speed of 709 km/h

(440 mph) over three passes. This record remains (as of 2012) the fastest speed

ever attained by a piston-engine seaplane. After this success, the M.C.72 was

never flown again.

One M.C. 72, the aircraft that took the world record, survives. It is on display at the Italian Air Force Museum, near Rome.

| THE KIT |

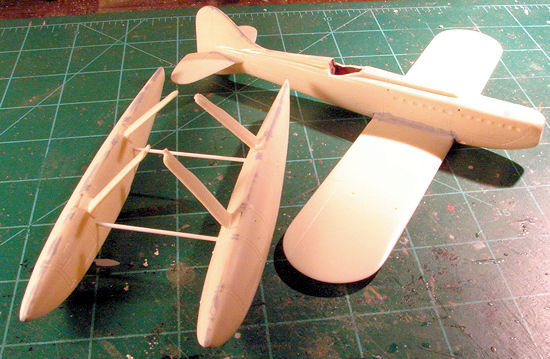

Crudely

molded in a light crème plastic, detail is somewhat lacking. It looks, at first,

to be a simple kit with just 21 parts. Later I found out it is typical SMER.

There is flash on most of the parts and they will require work to clean up.

Although there are numbers on the instructions, there are no part numbers on the

sprues. Holes are predrilled for the rigging.

Crudely

molded in a light crème plastic, detail is somewhat lacking. It looks, at first,

to be a simple kit with just 21 parts. Later I found out it is typical SMER.

There is flash on most of the parts and they will require work to clean up.

Although there are numbers on the instructions, there are no part numbers on the

sprues. Holes are predrilled for the rigging.

The

instructions are typical SMER... a simple exploded view showing where the parts

go. All the typing is in Czech, so I have no idea what any of it says. The back

page has a out-of-register color 3 view drawing. A small piece of acetate is

included for the windscreen.

A small decal sheet contains Tricolors for the tail and Macchi ID's for the fuselage. It also has a decal for the included stand. Unfortunately, the decals in my kit were unusable.

| CONSTRUCTION |

First thing I did was remove all the parts from the sprues and clean them up. I

found that the long brace parts were not going to be usable, so I made new ones

out of round stock. Careful test fitting is required to get all the parts to fit

together reasonable well, but filler will still be needed.

I

decided to start with the floats. I squared up the holes for the strut mounts as

best I could, then glued the 2 halves together. Be careful when fitting the

float struts, because they are left, right and front, rear handed. It took me

awhile to figure out which one when where. After attaching them, I filled the

gaps with 3M Spot and Glazing Putty... and there are a

I

decided to start with the floats. I squared up the holes for the strut mounts as

best I could, then glued the 2 halves together. Be careful when fitting the

float struts, because they are left, right and front, rear handed. It took me

awhile to figure out which one when where. After attaching them, I filled the

gaps with 3M Spot and Glazing Putty... and there are a

Turning to the fuselage, I glue the 2 halves together, leaving the prop until

later. There is no interior to speak of and I didn't bother to add one. Some

folks will want to remedy this, but I am more interested in the aircraft then

the details. The 2 one piece wings were then added. More filler was required

here as well.

Joining the floats to the fuselage is a study in dexterity. It's times like this one wishes they had 4 hands. There are 4 small holes in the lower fuselage that accept small pins on the float struts. I had to open these holes with micro files to even come close how they should fit. Even then, I had to work slowly and carefully fitting the floats. I made a simple jig out of paint bottles to hold the plane while the glue set. Out came the 3M here as well.

| COLORS & MARKINGS |

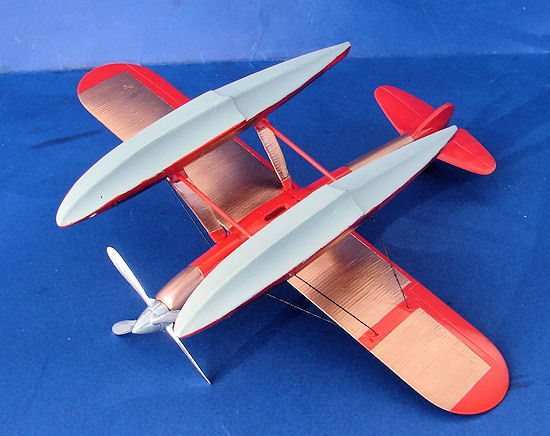

When the

plane was fully assembled, I shot it with Krylon Italian Red. Being assembled

makes it a bit harder to paint, but doing so beforehand, would have made

mounting the floats even more of a job. Once the red had dried a few days, I

painted the bottoms of the floats light gray. I painted the surface radiators MM

Copper. I suppose brass would have been a better choice, but I thought the

copper just looked nicer. I have seen photos of other models with the radiators

outlined in white, but shots of the plane on display do not show the white. You

can't really tell from period photos, but I chose not to add the white stripes.

Exhaust details were painted MM Flat Black. The props were painted with MM

Chrome.

When the

plane was fully assembled, I shot it with Krylon Italian Red. Being assembled

makes it a bit harder to paint, but doing so beforehand, would have made

mounting the floats even more of a job. Once the red had dried a few days, I

painted the bottoms of the floats light gray. I painted the surface radiators MM

Copper. I suppose brass would have been a better choice, but I thought the

copper just looked nicer. I have seen photos of other models with the radiators

outlined in white, but shots of the plane on display do not show the white. You

can't really tell from period photos, but I chose not to add the white stripes.

Exhaust details were painted MM Flat Black. The props were painted with MM

Chrome.

| FINAL BITS |

The

rigging was done with .8mil nylon monofilament. There should be more rigging

between the float struts, but I forgot to set the rigging holes before

installing them, so, no rigging. After the rigging was all in place, I tightened

it with a bit of heat and painted it flat black. The 2 props were glued together

and the press fitted to the nose. (you can see one of the down sides to

monofilament in the photos. I took the photos outside and it was bit chilly and

one of the lines began to sag. It tightened back up when I bought the model back

inside)

The

rigging was done with .8mil nylon monofilament. There should be more rigging

between the float struts, but I forgot to set the rigging holes before

installing them, so, no rigging. After the rigging was all in place, I tightened

it with a bit of heat and painted it flat black. The 2 props were glued together

and the press fitted to the nose. (you can see one of the down sides to

monofilament in the photos. I took the photos outside and it was bit chilly and

one of the lines began to sag. It tightened back up when I bought the model back

inside)

| CONCLUSIONS |

This is not a kit for the novice builder, but then most SMER kits are like that. The amount of filling and sanding that is required would drive them out of the hobby. However, it does build into a very nice looking MC72 and I believe the only other choice is a rather expensive resin kit.

December 2012

Copyright ModelingMadness.com. All rights reserved. No reproduction in part or in whole without express permission from the editor.

If you would like your product reviewed fairly and fairly quickly, please contact the editor or see other details in the Note to Contributors.

Back to the Review Index Page 2024