|

KIT: |

Classic Airframes 1/48 Sea Hawks |

|

KIT # |

465 / 490 |

|

PRICE: |

$54.95 MSRP |

|

DECALS: |

See review |

|

REVIEWER: |

Tom Cleaver |

|

NOTES: |

Multimedia kits with resin parts. |

|

HISTORY |

The Hawker Sea Hawk was the first completely successful British jet-powered carrier fighter. It was roughly equivalent to the U.S. Grumman F9F Panther, with which it shared a powerplant - the very successful Nene centrifugal turbojet - and of similar performance to the U.S. Navy's jet mainstay of the Korean War. While the Sea Hawk began its development process two years prior to the Panther, it first flew in the same year as the XF9F-2, and yet it entered service with the Fleet Air Arm in 1951, three years after the Panther had reached the same milestone. Even so, it was the most successful British jet of the to be developed in the immediate postwar period, a time marked by a strange technological lethargy in the British aviation industry.

The P.1040, as the Sea Hawk was initially know at Hawkers, began as a proposal for a single-engine jet fighter in the fall of 1944, which was not acted on until nearly a year later when it was rejected by the Air Ministry in favor of maximizing production of Meteors and Vampires. In January 1946, the design was proposed to the Admiralty as a carrier-based fighter; this resulted in an order in May 1946 for three prototypes, the first of which flew September 2, 1947 - within a few months of the XF9F-2 in the U.S.

The most original feature was the bifurcated

engine exhaust, which neatly solved the problem of excessive loss of

thrust associated with early turbojets when a longer exhaust pipe was

used. While the casual observer might think the Sea Hawk was a

twin-engine design like the McDonnell F2H Banshee, it had a single Nene

at the center of gravity, which greatly aided its handling in flight.

Pilots enjoyed the outstanding handling characteristics of the Sea Hawk,

which were in direct opposition to the Supermarine Attacker, the other

naval jet fighter under development at the time. Pilots particularly

liked the fact the cockpit was as far forward as it was, giving good

visibility for both combat and carrier landings.

The most original feature was the bifurcated

engine exhaust, which neatly solved the problem of excessive loss of

thrust associated with early turbojets when a longer exhaust pipe was

used. While the casual observer might think the Sea Hawk was a

twin-engine design like the McDonnell F2H Banshee, it had a single Nene

at the center of gravity, which greatly aided its handling in flight.

Pilots enjoyed the outstanding handling characteristics of the Sea Hawk,

which were in direct opposition to the Supermarine Attacker, the other

naval jet fighter under development at the time. Pilots particularly

liked the fact the cockpit was as far forward as it was, giving good

visibility for both combat and carrier landings.

The Sea Hawk F.Mk.1 was ordered into production in 1949. The outbreak of the Korean War gave added impetus to the need for the airplane, but Hawker was now deeply involved in the problems associated with creation of the Hunter. Production was shifted to Sir W. G. Armstrong Whitworth Aircraft, which had responsibility for further development and all production past the first 35 F.Mk.1s, the first of which flew November 14, 1951.

Service trials with the Hawker-built aircraft occupied most of 1952 while production hit its stride at Armstrong-Whitworth. 806 became the first operational Sea Hawk squadron in March 1953.

Following production of 60 Mk.1s, 40 F. Mk.2s

appeared with powered controls. The demand for increased operational

versatility was met with 116 F.B.Mk.3s which could carry bombs in place

of the underwing drop tanks. The 97 FGA Mk.4s appeared with a "4 store"

wing and the ability to carry rockets outboard of the pylons, but

performance suffered. The Admiralty decided to upgrade the FB Mk.3s and

FGA Mk.4s with the Nene 103, offering an increase in power from 5,000 to

5,200 lbs of thrust, to be known as the FGA Mk. 5 and Mk.6 respectively.

Few were re-engined, but 87 new-build FGA Mk.6s were taken into service.

When the last of these were delivered in January 1956, production of the

Sea Hawk for the FAA came to an end. The FGA.6 was the first variant of

the Sea Hawk to see combat action, providing close air support for the

Anglo-Israeli-French Suez operation, Operation Musketeer, in November

1956.

Following production of 60 Mk.1s, 40 F. Mk.2s

appeared with powered controls. The demand for increased operational

versatility was met with 116 F.B.Mk.3s which could carry bombs in place

of the underwing drop tanks. The 97 FGA Mk.4s appeared with a "4 store"

wing and the ability to carry rockets outboard of the pylons, but

performance suffered. The Admiralty decided to upgrade the FB Mk.3s and

FGA Mk.4s with the Nene 103, offering an increase in power from 5,000 to

5,200 lbs of thrust, to be known as the FGA Mk. 5 and Mk.6 respectively.

Few were re-engined, but 87 new-build FGA Mk.6s were taken into service.

When the last of these were delivered in January 1956, production of the

Sea Hawk for the FAA came to an end. The FGA.6 was the first variant of

the Sea Hawk to see combat action, providing close air support for the

Anglo-Israeli-French Suez operation, Operation Musketeer, in November

1956.

In the spring of 1956, the Sea Hawk began a second production life, when the Royal Netherlands Navy ordered 22 to replace their Hawker Sea Furies; these were delivered between July 1957-January 1958. In March 1958 they became the first European fighter armed with the Sidewinder AAM, and remained in first-line service until 1964.

Following the Dutch order, the Federal German Republic ordered 64 FGA Mk.6s for its newly-reborn Marineflieger. These, the Sea Hawk Mk. 100 and 101, were distinguished by a larger vertical fin and rudder, and the first was delivered in February 1958. 52 of these were delivered knocked-down and assembled by the Focke-Wulf Company, which assumed responsibility for maintenance and repair.

In late 1959, the Indian Navy purchased 9 Sea

Hawk F.B. Mk.3s which were refurbished to Mk. 6 standards. This was

followed by an order for 14 new-build FGA Mk.6s in 1961, which became the

last new Sea Hawks built. 22 more ex-Royal Navy aircraft were purchased

in 1961-62. All served with No. 300 "White Tiger" squadron aboard INS "Vikrant."

28 German Mk.100 aircraft were purchased as attrition replacements in

1966. These Sea Hawks served as the first line fighter strength of the

Indian Navy until they were replaced by Sea Harriers in 1983-84, which

makes the Sea Hawk one of the longest-serving first-generation jet

fighters.

In late 1959, the Indian Navy purchased 9 Sea

Hawk F.B. Mk.3s which were refurbished to Mk. 6 standards. This was

followed by an order for 14 new-build FGA Mk.6s in 1961, which became the

last new Sea Hawks built. 22 more ex-Royal Navy aircraft were purchased

in 1961-62. All served with No. 300 "White Tiger" squadron aboard INS "Vikrant."

28 German Mk.100 aircraft were purchased as attrition replacements in

1966. These Sea Hawks served as the first line fighter strength of the

Indian Navy until they were replaced by Sea Harriers in 1983-84, which

makes the Sea Hawk one of the longest-serving first-generation jet

fighters.

Operation Musketeer:

"Operation Musketeer", the Anglo-French-Israeli plan to de-fang Egyptian President Gamal Abdel Nasser and regain control of the Suez Canal, was carried out in October and early November 1956. Sea Hawks were operated by 800, 802 and 810 Squadrons aboard HMS "Albion," 804 and 897 Squadrons aboard HMS "bulwark," and 899 Squadron aboard HMS "Eagle," making the Sea Hawk numerically the most important British airplane operational during the conflict.

The Sea Hawks - four squadrons of which flew

from the carriers HMS “Albion,” HMS “Bulwark,” and HMS “Eagle” - were

given the assignment of neutralizing the Egyptian Air Force and

protecting the Anglo-French strike aircraft against attacks by the

Egyptian MiG-15s, as well as defending the fleet against possible attacks

by the Il-28 "Beagle" aircraft the Egyptians were known to possess. Most

of these aircraft were grounded because the Egyptians did not have enough

trained crews yet to man them. The Sea Hawks neutralized the Egyptian

Air Force bases and then proceeded to provide close air support to the

Anglo-French paratroops dropped in the Canal Zone, and proved as adept at

this work as had the Grumman Panther during the Korean War. Only two Sea

Hawks were lost to operational causes during this action.

The Sea Hawks - four squadrons of which flew

from the carriers HMS “Albion,” HMS “Bulwark,” and HMS “Eagle” - were

given the assignment of neutralizing the Egyptian Air Force and

protecting the Anglo-French strike aircraft against attacks by the

Egyptian MiG-15s, as well as defending the fleet against possible attacks

by the Il-28 "Beagle" aircraft the Egyptians were known to possess. Most

of these aircraft were grounded because the Egyptians did not have enough

trained crews yet to man them. The Sea Hawks neutralized the Egyptian

Air Force bases and then proceeded to provide close air support to the

Anglo-French paratroops dropped in the Canal Zone, and proved as adept at

this work as had the Grumman Panther during the Korean War. Only two Sea

Hawks were lost to operational causes during this action.

The Sea Hawk in the Indian Navy:

Though the Sea Hawk had been operated by the

Indian Navy since 1961, the aircraft did not see combat until the 1971

India-Pakistan war, in which the state of Bangladesh was born from what

had been East Pakistan. In the previous wars with Pakistan and China,

Indian leaders had no clear aim in mind and were merely reacting to

events. During the 1962 India-China war, for instance, the Indian

government ordered the IAF to withdraw its fighter bomber squadrons from

the north-east,  though these aircraft could have changed the course of

the war had they been allowed to hit the tenuous Chinese logistics lines.

During the 1965 India-Pakistan conflict, the Navy was kept in port and

did not engage in any offensive action.

though these aircraft could have changed the course of

the war had they been allowed to hit the tenuous Chinese logistics lines.

During the 1965 India-Pakistan conflict, the Navy was kept in port and

did not engage in any offensive action.

Because East and West Pakistan were two separate entities more than 1,600 miles apart, the only way Pakistani forces in East Pakistan could be sustained was by sea. The Indian Navy was given the strategic task of denying both East and West Pakistan access to war supplies, by means of a complete naval blockade of both parts of Pakistan.

The Indian Navy's best and biggest warship was its aircraft carrier, INS “Vikrant,” a British “Warrior” class World War II vintage ship. Because one of her main boilers was out of operation, she could not maintain the speed required for maneuvering in a situation where there was a serious air threat. Because of this, “Vikrant” would be used to blockade the ports in East Pakistan.

On December 4, the first day of war, “Vikrant” - which had been anchored off the Andaman & Nicobar islands - moved towards the principal East Pakistani port, Chittagong. The Pakistanis sent the submarine PNS “Ghazi” to enter Vizag harbor, the principal naval port in the Indian east coast, to sink the carrier. However, “Ghazi” was detected and sunk before it could make an attack.

That afternoon,

16 Sea Hawks - a mixed force of FGA.6s and Mk. 100s from 300 Squadron -

were launched in two 8-plane waves, the first against Cox's Bazaar and

the second against Chittagong. The Sea Hawks went in at low level using

rockets and bombs in repeated attacks on the airfields to neutralize the

possibility of a Pakistani strike against the task force. The next

morning, December 5, the Sea Hawks made strikes on the Mangla-Khulna

area. On December 6 they returned to Chittagong and worked over the

harbor thoroughly, sinking ships and hitting the airfield a second time.

The Sea Hawks inflicted substantial damage and suffered no losses. These

strikes constituted the second and last combat operation the Sea Hawk

would participate in.

That afternoon,

16 Sea Hawks - a mixed force of FGA.6s and Mk. 100s from 300 Squadron -

were launched in two 8-plane waves, the first against Cox's Bazaar and

the second against Chittagong. The Sea Hawks went in at low level using

rockets and bombs in repeated attacks on the airfields to neutralize the

possibility of a Pakistani strike against the task force. The next

morning, December 5, the Sea Hawks made strikes on the Mangla-Khulna

area. On December 6 they returned to Chittagong and worked over the

harbor thoroughly, sinking ships and hitting the airfield a second time.

The Sea Hawks inflicted substantial damage and suffered no losses. These

strikes constituted the second and last combat operation the Sea Hawk

would participate in.

On March 4, 1976, the catapult on “Vikrant” malfunctioned as Commander Peter Debras was being launched and his Sea Hawk splashed down and sank directly in front of the carrier, which then steamed directly over the top of the aircraft! Debras waited until it had passed over before ejecting from a depth of nearly 100 feet and being rescued. It was the world's deepest successful ejection.

The Indian Navy continued to operate their Sea Hawks until 1983-84, when they were finally replaced by Hawker Sea Harriers.

|

THE KIT |

For a look at what’s in the box, you can check these two previews (FGA.6 / Mk.101).

The Classic Airframes kit is the first injection-molded Sea Hawk to be produced in 1/48 scale, the only other 1/48 kit of the Sea Hawk being a very good - but difficult to build - vacuform from Falcon released in the mid-1980s and still available. MPM have recently produced Sea Hawks in 1/72 scale, and Airfix released a 172 Sea Hawk in the 1960s.

|

CONSTRUCTION |

I had originally intended to do one of these wings-up and one wings-down. However, researching photos of the wingfold area revealed that the kit-supplied detail for this is really deficient, thus requiring a lot more scratchbuilding than I was in the mood to do in order to get anything that looked half-right. In addition, the Sea Hawk - which is one of the most aesthetically-pleasing first-generation “plank wing” jets - loses all that visual charm when its wings get folded (in my opinion). Thus, both were done wings-down and I decided to create a representative of each of the combat operations the airplane was involved in.

Scott Van Aken’s account of building this kit

is very thorough. I will only add that even after grinding away as much

of the resin cockpit as I could, and sanding the plastic floor so it

would sit as deep in the lower fuselage as possible, I still had the

devil’s own time getting the forward fuselage together. I ended up

super-gluing one side, then clamping the fuselage and repeating the

process on the other side. And then I still used putty and Mr. Surfacer

to get rid of some pretty godawful

seams. Fit of the rear fuselage also

left something to be desired, and I put in some rabs made of evergreen

sheet to provide more “grab surface: in gluing the aft fuselage to the

forward part. The wings on my kits didn’t join as smoothly as Scott

relates, even using the plugs, which resulted in a considerable

expenditure of Mr. Surfacer 500 and several grades of sandpaper over all

the joints of all the parts of the model. As the atmosphere over the

workbench began to take on a purple hue, I wondered for about an hour or

so just how much I really wanted injection-molded Sea Hawk models in my

collection, given the very nice Falcon vacuform I’ve done. Perseverance

paid off; I sanded down and polished the models, and then rescribed them

in sufficient detail to look good.

seams. Fit of the rear fuselage also

left something to be desired, and I put in some rabs made of evergreen

sheet to provide more “grab surface: in gluing the aft fuselage to the

forward part. The wings on my kits didn’t join as smoothly as Scott

relates, even using the plugs, which resulted in a considerable

expenditure of Mr. Surfacer 500 and several grades of sandpaper over all

the joints of all the parts of the model. As the atmosphere over the

workbench began to take on a purple hue, I wondered for about an hour or

so just how much I really wanted injection-molded Sea Hawk models in my

collection, given the very nice Falcon vacuform I’ve done. Perseverance

paid off; I sanded down and polished the models, and then rescribed them

in sufficient detail to look good.

The injection-molded canopies are too thick,

and not really the right shape in either profile or in overall shape of

the windshield - which is pretty obvious when one looks at any photos of

the type. Fortunately, I had two Falcon vacuform canopies for the Sea

Hawk, and decided to use them. This necessitated filling in all the area

of the forward cockpit sill with putty and sanding it smooth, then

applying Mr. Surfacer. However, the canopies went on with no problem

afterwards and look far superior, being very thin and clear. I also

replaced the resin ejection seat of the Royal Navy FGA.6 model with a KMC

resin Martin-Baker Mk.2 seat with molded-in seatbelt detail (I sure do

wish whoever has the KMC molds would re-release those seats - I have now

run out of them, and they’re perfect for first and second-generation

British jets, and sure look superior to the kit seats here). For those

who want to replace the canopy, those can be obtained from Falcon in New

Zealand.

The injection-molded canopies are too thick,

and not really the right shape in either profile or in overall shape of

the windshield - which is pretty obvious when one looks at any photos of

the type. Fortunately, I had two Falcon vacuform canopies for the Sea

Hawk, and decided to use them. This necessitated filling in all the area

of the forward cockpit sill with putty and sanding it smooth, then

applying Mr. Surfacer. However, the canopies went on with no problem

afterwards and look far superior, being very thin and clear. I also

replaced the resin ejection seat of the Royal Navy FGA.6 model with a KMC

resin Martin-Baker Mk.2 seat with molded-in seatbelt detail (I sure do

wish whoever has the KMC molds would re-release those seats - I have now

run out of them, and they’re perfect for first and second-generation

British jets, and sure look superior to the kit seats here). For those

who want to replace the canopy, those can be obtained from Falcon in New

Zealand.

A word about weight: I crimped several fish

weights and put them under the cockpit, and then discovered after

test-fitting the rear fuselage that I needed more weight, so I added five

more fish weights immediately behind the cockpit.

A word about weight: I crimped several fish

weights and put them under the cockpit, and then discovered after

test-fitting the rear fuselage that I needed more weight, so I added five

more fish weights immediately behind the cockpit.

Regarding the resin interior parts: the main gear well has to have the resin plug cut off at least 1 inch in from either end, and the well needs to be sanded down until the roof is paper-thin and you can see light through it, in order to fit properly when the fuselage halves are joined. I don’t know what to say about the cockpit - if I did another I think I would cut off all the resin other than the immediate walls of the tub, and use a piece of .010 Evergreen sheet styrene to replace the floor the cockpit is attached to, in order to get the nose area to join up.

I also drilled out the 20mm cannon ports in both models by using a large paperclip, heated and then “drilled” in each position. There are shell ejection ports just inboard of the extended ports, and I created these by using a small screwdriver, heating it and then opening each port. The locations of these are in the engraved detail.

I also replaced the photo-etch splitter plate and fences in the air intakes with parts made from .010 Evergreen sheet.

Overall, the production design of this kit results in a model that is more difficult to get right than one expects. If you’ve purchased one of these and it’s only your first or second limited-run kit, put it back in the stash and wait till you have more experience. That said, the end result will look good and is worth the effort.

|

COLORS & MARKINGS |

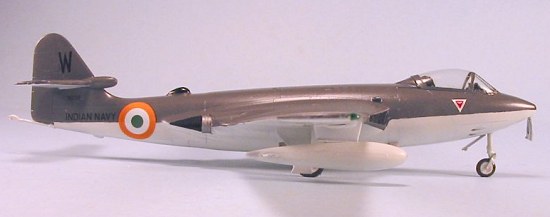

Painting was easy. The Indian Navy Sea Hawk is done in the “late style” of Royal Navy Sea Hawks, with the entire upper half of the airplane in Extra Dark Sea Grey and the lower surfaces in White. I used Tamiya Dark Sea Grey and Gunze-Sangyo “Off-White” for this.

The FGA.6 has the standard “early” Royal Navy

scheme. I used the new Xtracrylix paints, which are accurate in color

and dry semi-gloss. These were thinned with rubbing alcohol and I

experienced no difficulty using these paints. They dry to the touch

within 15 minutes, and dry hard enough to mask over within an hour,

thinned 50-50 with rubbing alcohol.

thinned 50-50 with rubbing alcohol.

In both cases, I painted the upper color first, then masked it and painted the lower color. It’s not an easy masking job, but it is easier than doing the reverse.

Both models were pre-shaded before their final colors were applied. When the paint was dry, each was given a good coat of Future.

Decals:

The decals are by MicroScale and present no

difficulty in application with a coat of Micro-sol. I particularly liked

the invasion-stripe decals, given that the area of the fuselage to be

covered with stripes is hard to do by painting and masking. One thing:

the only airplane on the sheets that is an Operation Musketeer airplane

is XE409, the FGA.6 from 804 Squadron - this unit was based on HMS

“Bulwark,” not on HMS “Ark Royal” (I don’t think “Ark Royal” was even

there, and if she was, she didn’t have any Sea Hawks aboard). A

15-minute Google session came up with several photos of 804 Squadron Sea

Hawks during Operation Musketeer, including XE409. The ship-identity

letter should be “B”, not “O.” I cut the “B” from the decals for the

German Sea Hawk and substituted that.

The decals are by MicroScale and present no

difficulty in application with a coat of Micro-sol. I particularly liked

the invasion-stripe decals, given that the area of the fuselage to be

covered with stripes is hard to do by painting and masking. One thing:

the only airplane on the sheets that is an Operation Musketeer airplane

is XE409, the FGA.6 from 804 Squadron - this unit was based on HMS

“Bulwark,” not on HMS “Ark Royal” (I don’t think “Ark Royal” was even

there, and if she was, she didn’t have any Sea Hawks aboard). A

15-minute Google session came up with several photos of 804 Squadron Sea

Hawks during Operation Musketeer, including XE409. The ship-identity

letter should be “B”, not “O.” I cut the “B” from the decals for the

German Sea Hawk and substituted that.

Unfortunately, the Mk.100 sheet doesn’t include the leaping White Tiger insignia carried by 300 Squadron; however, there are a number of photos from the 1971 war that show the Sea Hawks without the distinctive unit insignia, so doing without is historically accurate. I have to say that I was unable to find any photos of Indian Navy Sea Hawks in any scheme but the one I did; what is shown in the kit instructions may be for a Mk.100 shortly after arrival from the Germans, but apparently it would have been repainted quickly to conform to the standard scheme of the earlier airplanes which had all been delivered in the then-standard FAA scheme.

|

FINAL CONSTRUCTION |

Once the decals were set and the models had been washed to get rid of dried setting solution, they were given another coat of Future, followed by a coat of Glosscote with a little Dullcote mixed in to get a not-too-shiny gloss finish, which is more accurate for the actual aircraft.

The landing gear went on without problem.

The landing gear went on without problem.

If you place the drop tanks on the FGA.6 where the instructions show you should drill out the holes, you will have trouble with fitting the drop tank around the gear, as Scott reported. A photo of 804 Squadron Sea Hawks shows that the inner pylon is just inboard of the wing fold line; if you attach the pylon to the tank, and then glue it in that position so that the fins of the tank are just to the rear of the landing gear, it will end up in the correct position. Cut off the mounting pins to do this. There is no similar problem with the Mk.100, since its pylons are all out on the folding section of the wing.

I used underwing rockets from an Airfix Spitfire 24 kit to arm the 804 Squadron airplane. I am not certain what kind of bombs the Indians used in 1971, so I have left the Mk.100 unarmed until I find out more.

Photos of these airplanes in both units show them very clean and well-maintained, so I did not weather them further.

|

CONCLUSIONS |

The models are more difficult to build than they look in the box, or appear to be even after test-fitting the main parts. The big problem is shoehorning the resin interior parts into position so the rest of the kit can be assembled. That said, these are certainly not the “monsters” the C-A Blenheims were. The end result of either kit is a good-looking model of an important first-generation jet fighter.

August 2004

Thanks to Classic Airframes for the review kits.

If you would like your product reviewed fairly and quickly by a site that has over 250,000 visitors a month, please contact me or see other details in the Note to Contributors.