Contrail 1/72 Short Sturgeon TT.2

|

KIT #: |

? |

|

PRICE: |

£6.00 |

|

DECALS: |

One Option |

|

REVIEWER: |

Carmel

J. Attard |

|

NOTES: |

Vacform kit with cast white metal props and plastic undercarriage

items |

The Sturgeon was designed as a torpedo

bomber/reconnaissance aircraft for use by the Royal Navy new aircraft carriers

and when submitted to the Admiralty, gained a contract for three prototypes.

However the torpedo carrying requirement soon cancelled and when construction of

the carriers was postponed at the end of WWII, the Sturgeon intended role no

longer existed.

A

decision was taken to convert it as a high speed target–tug against a new

specification, Q.1/46. Although the first two aircraft were Sturgeon S.A.1 and

Sturgeon S. Mk 1 gunnery trainers with provision for armament, the third became

the S.A. Sturgeon TT Mk2 prototype which resulted in an order for 23 production

aircraft. It featured a contra rotating propeller on two 1660 HP Rolls Royce

Merlin 140 engines. The small diameter propellers allowed close inboard mounting

of the engines which gave a compact form where the wings were folded. The

Sturgeon had a maximum speed of 370mph and could tow a 32ft winged target to an

altitude of 32,000 ft. Some were converted to Sturgeon Mk3 standard which were

used from shore bases mostly in

Malta

operating alongside TT2s. In a bid to make the Sturgeon suitable for

anti-submarine work, the 24th and

last airframe was modified to become the SB3. A deep nose was added, housing a

radome scanner and two operators and it was powered by two 1,475 shp Armstrong

Siddeley Mamba turboprops. Flown in August 1950 it was not a success and the

requirement was met by the Fairey Gannet AEW Mk3.

A

decision was taken to convert it as a high speed target–tug against a new

specification, Q.1/46. Although the first two aircraft were Sturgeon S.A.1 and

Sturgeon S. Mk 1 gunnery trainers with provision for armament, the third became

the S.A. Sturgeon TT Mk2 prototype which resulted in an order for 23 production

aircraft. It featured a contra rotating propeller on two 1660 HP Rolls Royce

Merlin 140 engines. The small diameter propellers allowed close inboard mounting

of the engines which gave a compact form where the wings were folded. The

Sturgeon had a maximum speed of 370mph and could tow a 32ft winged target to an

altitude of 32,000 ft. Some were converted to Sturgeon Mk3 standard which were

used from shore bases mostly in

Malta

operating alongside TT2s. In a bid to make the Sturgeon suitable for

anti-submarine work, the 24th and

last airframe was modified to become the SB3. A deep nose was added, housing a

radome scanner and two operators and it was powered by two 1,475 shp Armstrong

Siddeley Mamba turboprops. Flown in August 1950 it was not a success and the

requirement was met by the Fairey Gannet AEW Mk3.

What

was originally designed as a carrier based strike fighter has became a war

surplus that was then relegated to second line duties. The Short Sturgeon PR Mk1

had a short nose and carried three cameras in a ventral fairing. The TT Mk 2 had

a redesigned narrow long nose that differed from the PR Mk1.

It

was not as popular to spot in British skies as it was over the Mediterranean

apart form its development stage. The Sturgeon had provision for a winch gear

and represented a fast multi-purpose target-tug and gunnery trainer that entered

service with the Fleet Air Arm in 1949 as the TT2.

All of

the 23 aircraft produced served with 728 Squadron and the Fleet Requirement Unit

at Hal Far airfield in

Malta.

They served into the late 50s which was long enough for me to remember the type

as flying all day long on Target Towing sorties. You could spot the Sturgeon

from anywhere in the clear blue sky with its conspicuous yellow and black

stripes to the undersurface identification colour scheme. At the time the

Sturgeon operated along side a Target Towing Beaufighter which carried out

similar sorties for the Royal Air Force and the local Territorial’s Defense

Battery based at Bahar ic-Caq, near Salini. The Beaufighter operated from the

RAF Luqa airfield. These carried an orange tube like target which when returning

to base was released the target over the airfield to be retrieved by ground

crew. There were occasions when the target drifted outside the airfield

perimeter and vanished within minutes of touching the ground.

All of

the 23 aircraft produced served with 728 Squadron and the Fleet Requirement Unit

at Hal Far airfield in

Malta.

They served into the late 50s which was long enough for me to remember the type

as flying all day long on Target Towing sorties. You could spot the Sturgeon

from anywhere in the clear blue sky with its conspicuous yellow and black

stripes to the undersurface identification colour scheme. At the time the

Sturgeon operated along side a Target Towing Beaufighter which carried out

similar sorties for the Royal Air Force and the local Territorial’s Defense

Battery based at Bahar ic-Caq, near Salini. The Beaufighter operated from the

RAF Luqa airfield. These carried an orange tube like target which when returning

to base was released the target over the airfield to be retrieved by ground

crew. There were occasions when the target drifted outside the airfield

perimeter and vanished within minutes of touching the ground.

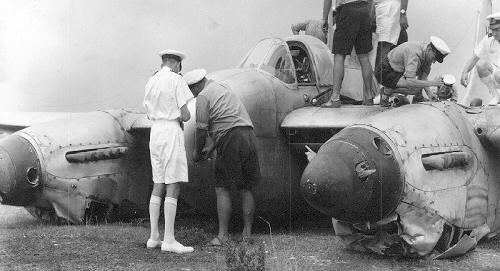

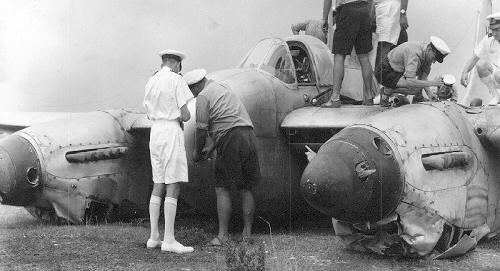

I recall aircraft wrecks at a small aircraft scrap

yard at Marsa and a Sturgeon fuselage was among them, others were stacked at a

disused field at Mosta where several fuselages were easily spotted from the main

road past the Mosta Dome in what was then a still unbuilt disused clear area.

This was in the late 50s, a time when the first Meteor TT20s started to arrive

to replace the ageing Sturgeons at Hal Far.

The

Short Sturgeon T2 kit by Contrail is another one from the British aircraft of

the 50s, and at its time was one of the more recent kits by the company to come

out on the market, by which time vacform kits have reached a high standard of

accuracy. A

comprehensive

instruction sheet contained 4 view scale line drawings, instructions suggesting

a method of construction and 4 very clear photographs of the operational

Sturgeon TT2. There are 32 vacform parts in white plastic and 7 transparent

pieces.

The vacform parts are beautifully

produced and to make things easier Aeroclub of Nottingham cast the contra

rotating propellers in white metal, and the undercarriage legs, exhaust stabs

and wheels for this kit were injected in black plastic. The propellers were of

good quality cast metal items and only a slight clean-up with a smooth file was

all that was required.

comprehensive

instruction sheet contained 4 view scale line drawings, instructions suggesting

a method of construction and 4 very clear photographs of the operational

Sturgeon TT2. There are 32 vacform parts in white plastic and 7 transparent

pieces.

The vacform parts are beautifully

produced and to make things easier Aeroclub of Nottingham cast the contra

rotating propellers in white metal, and the undercarriage legs, exhaust stabs

and wheels for this kit were injected in black plastic. The propellers were of

good quality cast metal items and only a slight clean-up with a smooth file was

all that was required.

The kit contained vacform canopies which were clear

enough to allow a certain amount of detail added inside such as seat straps

instrument panel etc to be visible. The clear nose and cockpit Perspex had the

tendency to turn yellowish with time unfortunately. The main components are

formed out of a white 30 thou sheet which is of suitable thickness for a large

kit as the Sturgeon is. At sharp corners the plastic tended to be thin and at

places like the wing roots required reinforcement. The main parts needed the

cutting, shaping/ sanding with wet and dry in the usual standard procedure

practiced with vacform kits. The parts were excellent in shape and a certain

amount of time was needed to arrive to the correct section width of parts before

the fuselage interior could be added.

I have first scored around the mouldings and snapped

off waste plastic. Components were carefully rubbed down the joining surfaces on

wet and dry paper glued onto a flat board. A thin surface was achieved at the

wing trailing edges, tail planes and rudder before gluing the halves together.

The edges of the moulded nose transparencies were cut and the edges shaped.

Cockpit decking was also cut and small side windows opened with a pointed blade.

Also a section of the lower nose was cut and shaped the front rectangular

windows.

The 4 fuselage bulkheads

were cut and glued in positions as per instructions. The cockpit floor is added

and seats glued to the pilot office and for the winch operator accommodated at

the rear round canopy. The cockpit was painted interior green and instruments in

black with white gauges. Other detail as control column, rudder pedals and side

instruments were added to t he

interior. Small tabs of plastic taken from discarded/waste plastic were cut and

glued at suitable places around the inner edge of one fuselage half. These are

necessary to act as guides when locating the two halves together. The two halves

were checked for correct fit, glued together and set aside to dry.

he

interior. Small tabs of plastic taken from discarded/waste plastic were cut and

glued at suitable places around the inner edge of one fuselage half. These are

necessary to act as guides when locating the two halves together. The two halves

were checked for correct fit, glued together and set aside to dry.

Reference to photos gave

a clear indication of how the flaps would appear when lowered. This was extra

work that I made to the Sturgeon model by lowering the flaps. The flaps were cut

carefully with a sharp X-acto blade and were then glued in lowered position. The

engine nacelles were two separate sub assemblies. These were cut, trimmed,

sanded, and interior structural detail added. The undercarriage door and chin

radiator also cut as per reference drawing given. Two small discs of thick

plastic sheet were cut to fit inside each nacelle. A simulated radiator was made

from scrap, cut to fit 2mm back from chin opening and glued into one half of

each nacelle. Into the top of each nacelle a 1.5mm scrap of plastic was glued

and a hole was drilled to take the undercarriage leg. The two nacelles were then

glued and brought to the corresponding wing openings. A wing spar was cut to

pass through a slot cut in the fuselage sides and into each wing by about 1

inch. The wings are cemented to the wing spar and to the fuselage sides, checked

for alignment and allowed to set. Tail planes and fin were then added to the

fuselage and allowed to set. Filler was added to mall areas around the joint

lines. Finally the nose, cockpit canopy and rear dome were trimmed and fitted to

the fuselage. Side windows were glazed with Kristal Kleer. Undercarriage doors,

legs, exhaust stabs, and antennae were added as the last items to goon the kit.

Being a TT version, wire guards made from thin fishing line was added at

appropriate places to prevent the towing rope from entangling with control

surfaces.

The

Sturgeon TT2 based at Hal Far, Malta were painted in a standard TT colour scheme

having top and fuselage sides in aluminium, the undersides were trainer yellow

and black diagonal stripes. A yellow band went around the rear fuselage and over

the top surfaces of the wings outboard of the engines. The TT2 production

started at

Belfast in

1949 comprising 24 aircraft with RN serials TS475-498. What appeared to be a

dorsal turret was in fact a camera cupola for target observation. Decals

supplied with the kit were of top quality and all adhered very well. The

markings that came with the kit catered for a TT2 that was based at Hal-Far,

Malta

circa 1958 attached to 728 Squadron with registration TS486/591.

The

Sturgeon TT2 based at Hal Far, Malta were painted in a standard TT colour scheme

having top and fuselage sides in aluminium, the undersides were trainer yellow

and black diagonal stripes. A yellow band went around the rear fuselage and over

the top surfaces of the wings outboard of the engines. The TT2 production

started at

Belfast in

1949 comprising 24 aircraft with RN serials TS475-498. What appeared to be a

dorsal turret was in fact a camera cupola for target observation. Decals

supplied with the kit were of top quality and all adhered very well. The

markings that came with the kit catered for a TT2 that was based at Hal-Far,

Malta

circa 1958 attached to 728 Squadron with registration TS486/591.

Many may

have been put off when they see a vac-form kit in view of the time and the

little extra effort involved to build the model. With a kit like the Sturgeon

which contained injected and cast components, and with an excellent fit of

parts once prepared, this may not be the case. This kit should be a good

starting point for new comer to vacform. The kit should also appeal to post-war

British aviation enthusiasts.

Many may

have been put off when they see a vac-form kit in view of the time and the

little extra effort involved to build the model. With a kit like the Sturgeon

which contained injected and cast components, and with an excellent fit of

parts once prepared, this may not be the case. This kit should be a good

starting point for new comer to vacform. The kit should also appeal to post-war

British aviation enthusiasts.

Carmel J.

Attard

February 2009

Copyright ModelingMadness.com. All rights reserved. No reproduction in any form without expressed permission from the editor.

If you would like your product reviewed fairly and quickly, please

contact

the editor or see other details in the

Note to

Contributors.

Back to the Main Page

Back to the Review

Index Page 2025

All of

the 23 aircraft produced served with 728 Squadron and the Fleet Requirement Unit

at Hal Far airfield in

All of

the 23 aircraft produced served with 728 Squadron and the Fleet Requirement Unit

at Hal Far airfield in  comprehensive

instruction sheet contained 4 view scale line drawings, instructions suggesting

a method of construction and 4 very clear photographs of the operational

Sturgeon TT2. There are 32 vacform parts in white plastic and 7 transparent

pieces.

The vacform parts are beautifully

produced and to make things easier Aeroclub of Nottingham cast the contra

rotating propellers in white metal, and the undercarriage legs, exhaust stabs

and wheels for this kit were injected in black plastic. The propellers were of

good quality cast metal items and only a slight clean-up with a smooth file was

all that was required.

comprehensive

instruction sheet contained 4 view scale line drawings, instructions suggesting

a method of construction and 4 very clear photographs of the operational

Sturgeon TT2. There are 32 vacform parts in white plastic and 7 transparent

pieces.

The vacform parts are beautifully

produced and to make things easier Aeroclub of Nottingham cast the contra

rotating propellers in white metal, and the undercarriage legs, exhaust stabs

and wheels for this kit were injected in black plastic. The propellers were of

good quality cast metal items and only a slight clean-up with a smooth file was

all that was required. he

interior. Small tabs of plastic taken from discarded/waste plastic were cut and

glued at suitable places around the inner edge of one fuselage half. These are

necessary to act as guides when locating the two halves together. The two halves

were checked for correct fit, glued together and set aside to dry.

he

interior. Small tabs of plastic taken from discarded/waste plastic were cut and

glued at suitable places around the inner edge of one fuselage half. These are

necessary to act as guides when locating the two halves together. The two halves

were checked for correct fit, glued together and set aside to dry. The

Sturgeon TT2 based at Hal Far, Malta were painted in a standard TT colour scheme

having top and fuselage sides in aluminium, the undersides were trainer yellow

and black diagonal stripes. A yellow band went around the rear fuselage and over

the top surfaces of the wings outboard of the engines. The TT2 production

started at

The

Sturgeon TT2 based at Hal Far, Malta were painted in a standard TT colour scheme

having top and fuselage sides in aluminium, the undersides were trainer yellow

and black diagonal stripes. A yellow band went around the rear fuselage and over

the top surfaces of the wings outboard of the engines. The TT2 production

started at  Many may

have been put off when they see a vac-form kit in view of the time and the

little extra effort involved to build the model. With a kit like the Sturgeon

which contained injected and cast components, and with an excellent fit of

parts once prepared, this may not be the case. This kit should be a good

starting point for new comer to vacform. The kit should also appeal to post-war

British aviation enthusiasts.

Many may

have been put off when they see a vac-form kit in view of the time and the

little extra effort involved to build the model. With a kit like the Sturgeon

which contained injected and cast components, and with an excellent fit of

parts once prepared, this may not be the case. This kit should be a good

starting point for new comer to vacform. The kit should also appeal to post-war

British aviation enthusiasts.