Whirlykits 1/72 Fairey F.D. 1

| KIT #: | WPX72007 |

| PRICE: | $ |

| DECALS: | One Option |

| REVIEWER: | Martin Pohl |

| NOTES: | Vacuformed kit with metal parts |

| HISTORY |

Originally the Fairey F.D.1 was thought to be a vertical takeoff fighter, but

the proposed plane was then intended to be launched from an inclined ramp.

Already in the early design stage the Ministry of Supply changed their minds to

have this aircraft being

built as a more conventional jet-powered research

vehicle. The design was a mid-wing tail-less delta monoplane, with a circular

cross-section fuselage and engine air-inlet at the extreme front. The engine was

a

Rolls-Royce Derwent 8.

built as a more conventional jet-powered research

vehicle. The design was a mid-wing tail-less delta monoplane, with a circular

cross-section fuselage and engine air-inlet at the extreme front. The engine was

a

Rolls-Royce Derwent 8.

The first F.D.1 (VX350) made its maiden flight on

10

March

1951. Because of serious pitching when gathering speed the F.D.1 got

a small horizontal delta wing on the top of the tail-fin which was intended to

stop this. This additional tail surface limited the top speed to 345 mph (555

km/h).

After a landing accident in September 1951, the F.D.1 was modified with the

removal of the leading-edge wing slats as well as the removal of the streamlined

housings for the anti-spin parachutes that were mounted at the wingtips. With

limited flying after the test program was re-launched in May 1953, and no sign

of the resolution of considerable design deficiencies, the F.D.1 was soon

relegated to non-flying status. Only one F.D.1 was built also three were planned

(VX357 & VX364). The F.D.1 never achieved its design goals and it ended up as a

target in the Shoeburyness,

| THE KIT |

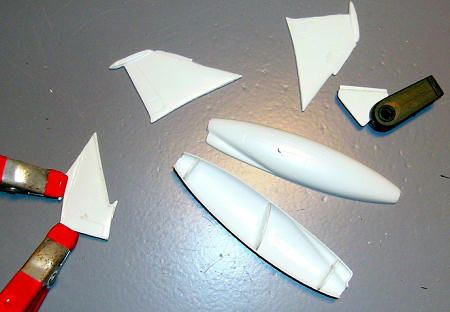

The kit comes in two

VAC formed plastic cards which will separate into 10 parts, the fuselage halves,

the wings, the small delta wing on top of the tail-fin and the tail-fin itself.

You get also 2 VAC formed canopies and 11 metal parts. Those metal parts

represent the landing gear (7 pieces), 2 for rocket motor fairings, the ejector

seat and the air intake divider. It looks like the molds of the metal parts are

a bit old so the ejector seat looks a little spongy, but as you will not see

that much of the cockpit with a closed canopy it is fair enough. The landing

gear does look good.

The kit comes in two

VAC formed plastic cards which will separate into 10 parts, the fuselage halves,

the wings, the small delta wing on top of the tail-fin and the tail-fin itself.

You get also 2 VAC formed canopies and 11 metal parts. Those metal parts

represent the landing gear (7 pieces), 2 for rocket motor fairings, the ejector

seat and the air intake divider. It looks like the molds of the metal parts are

a bit old so the ejector seat looks a little spongy, but as you will not see

that much of the cockpit with a closed canopy it is fair enough. The landing

gear does look good.

The VAC forming of

the plastic parts is done quite well, so the main panel lines are given. All the

smaller panel lines have to be scribed. This meets the expectations of a VAC

formed kit, at least mine.

| CONSTRUCTION |

Building VAC formed

kits always intends to do a little scratch build of some parts. For this

particular plane you’ll have to build the cockpit floor and of course all

cockpit details, beside the given ejector seat. You also will have to find a way

to ‘close’ the air intake and the engine hole at the end; otherwise you could

look through. For the landing gear doors there is not that much to do, as those

are closed on the ground. Only some small rectangular openings have to be done

and the inner detail has to be built up, otherwise you will not be able to fit

the landing gear.

Building VAC formed

kits always intends to do a little scratch build of some parts. For this

particular plane you’ll have to build the cockpit floor and of course all

cockpit details, beside the given ejector seat. You also will have to find a way

to ‘close’ the air intake and the engine hole at the end; otherwise you could

look through. For the landing gear doors there is not that much to do, as those

are closed on the ground. Only some small rectangular openings have to be done

and the inner detail has to be built up, otherwise you will not be able to fit

the landing gear.

The completed plane is very small as the fuselage length is less than 3.5 inches (9 cm).

| COLORS & MARKINGS |

After a complete

sanding the bird got a base of Createx Black Base. This was then polished and a

coat of Model Master Aluminum was then sprayed on top. This color drove me

crazy, cause it just does not want to dry, even after again 2 weeks. So I

stripped it  off and put a layer of Alclad Aluminum on. After this was dry, some

panels was masked an get a coat of a different Alclad tone, White Aluminium and

Flat Aluminium. In the end the anti glare black area was masked off and painted

with a flat black, Humbrol.

off and put a layer of Alclad Aluminum on. After this was dry, some

panels was masked an get a coat of a different Alclad tone, White Aluminium and

Flat Aluminium. In the end the anti glare black area was masked off and painted

with a flat black, Humbrol.

And now the decals,

those are made by Whirlybird decals and you will find a long description on how

to handle them. In the beginning they write: ‘…Our decals have no carrier film.

…’ - well this then means you have

to give them a coat – WRONG! – those decals seem to be dry transfers, so I

tested a piece and tried to rub it onto some sheet of plastic – nothing

happened, really nothing. So may be I’m too silly to rub on those dry transfers

but I ended up scanning those decals. I repainted them in a graphics program –

GIMP – and printed them on a decal sheet compatible with my ink jet printer. But

this then meant that I had to mask off the white areas, cause I used an

transparent decals sheet to print the remade decals on.

To say something positive on the decals; all decals you will need to build up a VX350, the one and only prototype, are there.

| CONCLUSIONS |

This example of a VAC

formed kit does not differ from others. The parts are formed OK and together

with the metal parts one can make a quite nice examples of the Fairey FD.1.

This example of a VAC

formed kit does not differ from others. The parts are formed OK and together

with the metal parts one can make a quite nice examples of the Fairey FD.1.

If you want to go for a VAC

formed kit and you are searching for one, then this could be a starter. For all

X-Planes or British aviation enthusiast out there this representation of the

Fairey F.D.1 is probably one choice you have, if you are able to purchase one.

So for those enthusiasts I give it a ‘go and get it’. For all the others it is

just a very small kit they most probably will not miss.

| REFEENCES |

Wikipedia

Flugzeuge von A bis Z, Band 2 (Bernard & Graefe Verlag)

October 2008

Copyright ModelingMadness.com. All rights reserved. No reproduction in part or in whole without express permission.

If you would like your product reviewed fairly and quickly, please contact the editor or see other details in the Note to Contributors.