Airfix 1/48 Gnat T.1

|

KIT #: |

A05123 |

|

PRICE: |

£16-99 |

|

DECALS: |

Two options |

|

REVIEWER: |

Frank

Reynolds |

|

NOTES: |

New tool kit |

The Folland Gnat was initially designed as a low cost lightweight single

seat interceptor fighter, armed with twin 30mm cannon and it first flew in

1955. It was designed by W.E.W Petter, the engineer whose talent included

the design of two highly influential military jet aircraft , the English

Electric Lightning and the Canberra. The single seater was not required by

its intended customer, the RAF, but was exported to Finland, Yugoslavia and

India, the latter building it under licence and developing it as the HAL

Ajeet. However the Royal Air Force issued a requirement for a high speed jet

trainer in 1957 and an extensively redesigned unarmed two seat Gnat first

flew in August 1959. The RAF issued orders for a series of production

batches, totalling 105 aircraft, the last being delivered in 1965.

Powered

by a Bristol Siddeley Orpheus engine of 4,700lb thrust, the little Gnat had

a wingspan of just 22ft 1in. and a length of 28ft 8ins. It was capable of

Mach 0.95. It was unconventional in size and appearance with its highly

loaded shoulder mounted wing and the fuselage mounted main undercarriage

served as the airbrakes. The tandem cockpit was a tight fit with the rear

seat occupant seemingly crammed into a notch in the leading edge of the wing

and hemmed in by the engine air intakes. It was also a mechanic’s nightmare

with equipment crammed into small spaces and it had needed the design of

special light weight ejector seats and miniaturised motors for the powered

flight controls.

Powered

by a Bristol Siddeley Orpheus engine of 4,700lb thrust, the little Gnat had

a wingspan of just 22ft 1in. and a length of 28ft 8ins. It was capable of

Mach 0.95. It was unconventional in size and appearance with its highly

loaded shoulder mounted wing and the fuselage mounted main undercarriage

served as the airbrakes. The tandem cockpit was a tight fit with the rear

seat occupant seemingly crammed into a notch in the leading edge of the wing

and hemmed in by the engine air intakes. It was also a mechanic’s nightmare

with equipment crammed into small spaces and it had needed the design of

special light weight ejector seats and miniaturised motors for the powered

flight controls.

The Gant was a hot ship but a useful link between a basic trainer such as

the Vampire and the front line Lightning. However it was not perfect, being

so small that pilots of above average stature could not comfortably fit in

and forcing the RAF to maintain some Hawker Hunter two seat trainers in

order to cope. The Gnat found its fame as the public face of the Royal Air

Force, equipping its official aerobatic team, the Yellow Jacks, in1962, that

evolved into the Red Arrows in 1964. The small, agile Gnat had a high rate

of roll and was ideal for a nine-ship flight demonstration team, remaining

in the public view until 1979 when the Red Arrows re-equipped with the BAE

Hawk.

This

is supplied in Airfix’s now familiar style of tray-type top opening box with

spectacular full colour artwork. There are three parts frames in pale blue

plastic and one of clear. A comprehensive decal sheet has extensive airframe

stencils and walkways and a choice of two colour finishes, both RAF, since this

air arm was the only user of this aircraft. They are:

Central Flying School, Little Rissington,

Gloucestershire

,England 1964 – an incredibly English location.

Silver airframe

with large areas of Dayglo Orange to nose, tail and wingtips.

No 4

Flying Training School, RAF Valley, Anglesey, Wales, 1973.

Mainly Red with

white fuselage flashes and Light Aircraft Grey under wings.

The

instructions run to twelve pages in an A4 booklet with full colour four-views

keyed to Airfix paint numbers and exploded views running to 38 stages of

construction,

The

instructions run to twelve pages in an A4 booklet with full colour four-views

keyed to Airfix paint numbers and exploded views running to 38 stages of

construction,

The

parts are sharply moulded with no trace of flash that I could find, although one

tiny part of an ejection seat headrest was short shot and needed a repair with a

small triangle of plastic card and similarly the rear corner of the lower right

wing tip. The etched surface detail seems to be more subtle than some of the

recent offerings from this manufacturer.

The

kit provides options that must be decided before construction :

It can be built

with the undercarriage retracted, using a stand that can be bought separately.

The canopy can be open or closed and separate mouldings are provided. Flaps and

control surfaces can be deflected. One pilot figure is provided but if not used,

there are separate seat cushions that have the straps moulded in. The hatch to

the nose avionics bay can be posed open. Wing mounted pinion tanks are optional.

A

close study of the instructions identified the optional parts that I would not

be using. These were cut from the parts frames and set aside in a ziplock bag,

just in case I had got it wrong or had a change of heart during the build. I

elected to have all of the control surfaces neutral and the nose bay closed up,

realising that if I omitted the nose bay avionics tray there would be room for

some nose weight before the hatch was glued shut.

The

breakdown of parts is a little unconventional, so instead of looking for

sub-assemblies I aimed to follow to the sequence set out in the instructions,

but with some minor variations to make painting easier. The interior parts were

pre-painted in their base colour while still on the parts frame using Tamiya

XF-20 Medium Grey.

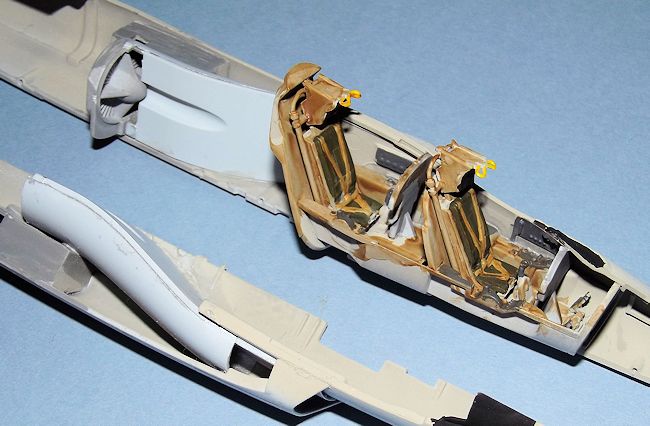

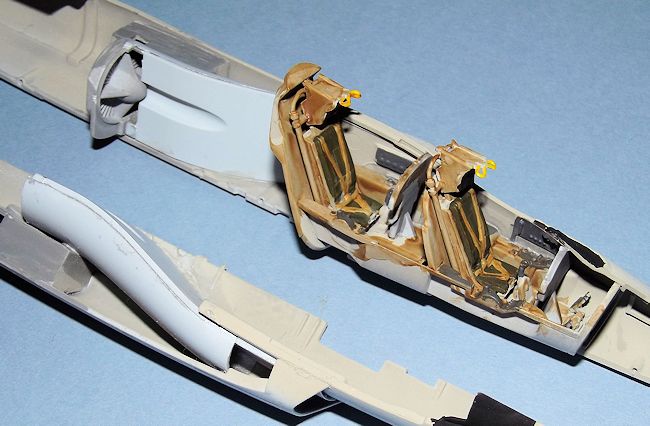

Construction

begins with the cockpit area and a tub forms the floor and side walls, to which

the front and rear bulkheads are glued. The nose wheel bay is a well detailed

box that glues into an opening under the rear seat position. The front and rear

instrument panels/pedestals have raised dials, detailed with instrument decals

that shrank over the raised detail with the application of a little Micro Sol.

Separate rudder bars are provided for each seat position.

Construction

begins with the cockpit area and a tub forms the floor and side walls, to which

the front and rear bulkheads are glued. The nose wheel bay is a well detailed

box that glues into an opening under the rear seat position. The front and rear

instrument panels/pedestals have raised dials, detailed with instrument decals

that shrank over the raised detail with the application of a little Micro Sol.

Separate rudder bars are provided for each seat position.

The

two ejection seats each consist of seven parts and the seat cushions were

painted Olive Green with the seat belts picked out in medium grey. The seats are

reasonably well detailed and include the skeleton mounting frame and tiny pull

handles to the head rests. The front seat is glued onto a dividing bulkhead and

the rear seat onto the rear bulkhead, but I decided to keep the seats separate

for the time being in case they needed any adjustment to clear the canopy. The

two stubby control sticks were glued in place and when dry, the cockpit area was

detailed by picking out some of the boxes and switches to the side panels in

matt Black, then gently dry brushing the cockpit are in Dark Grey to highlight

some of the detail. A quick search of the internet revealed a good range of

cockpit photos for reference purposes.

The

structure of the main airframe is a little unconventional and illustrates to art

of the toolmaker in the 21st

century. The fuselage halves are split conventionally but the intake fairings

from the side of the cockpit, all the way back past the trailing edge of the

wing, are separate sections. Once they are glued in place, they are followed

with a main wheel bay that is detailed with raised internal ribbing and a small

internal box with some pipework detail. Next follows a two-piece intake trunking

that features internal joints at the lower corners, effectively hiding the

joint. The interior of the intakes seems to be silver or white, depending on the

external colour scheme and I elected for matt silver. These sinuous intakes are

fitted from inside each fuselage half and if you trust the confidence and the

skill of the toolmaker they will settle do wn

inside the curves of the fuselage. Some time spent dry fitting before committing

to glue and joining the fuselage halves will pay dividends because the combined

parts are a very tight fit and even the thickness of a coat of paint can make a

difference.

wn

inside the curves of the fuselage. Some time spent dry fitting before committing

to glue and joining the fuselage halves will pay dividends because the combined

parts are a very tight fit and even the thickness of a coat of paint can make a

difference.

One

satisfied with the fit, I glued the engine front that joins the two intake

trunks into the right hand fuselage half, together with the jet exhaust, both of

which feature raised fan blade detail, although little of that can be seen,

buried deep within the structure. The cockpit tub was glued into the right hand

fuselage half and the two halves joined.

Attention now turns to the wing and the upper surface is moulded in one piece,

tip to tip, eliminating any problems with setting the angle of the wing’s

anhedral. Marked out holes need to be drilled out on the lower surfaces to

locate the pinion tanks, if required. The lower wing surfaces are in left and

right halves and intended to trap the ailerons when they are glued in place,

allowing them to pivot. Some Gnat colour schemes require the flight control

surfaces to be in a different colour from the surrounding structure, so some

builders might prefer to cut away the tiny hinge pivots so that the control

surfaces can be added after painting. By contrast, the adjoining trailing edge flaps are fixed in position and

alternative mouldings are provided or fixed or extended options.

By contrast, the adjoining trailing edge flaps are fixed in position and

alternative mouldings are provided or fixed or extended options.

The

wing drops in place as a large saddle-like structure that wraps around the rear

cockpit and once again it was a tight, but positive fit, requiring a minimum of

fettling to get to close up. The structure was left overnight to dry after which

the first order of business was to dry fit the ejector seats and test fit the

canopy and I found the need to shave down the base of the rear seat to allow the

canopy to sit down satisfactorily. So the seats were glued in followed by the

coaming between the front and rear cockpits and the clear blast screen for the

rear seat. The canopy was masked with Tamiya tape, trimmed with a fresh scalpel

blade and fixed with Humbrol Clear Fix. The masking was relatively simple,

since, unusually for a British-built aircraft of the period, the framing was

minimal.

I

decided to leave the tail planes off until final assembly, so that they could be

painted separately. The vertical tail consists of one half moulded into the left

fuselage side, to be completed with a separate panel glued onto the right side,

trapping the rudder in place. I trimmed off the tiny pivots on the rudder so

that too could be added after painting.

The

nose area of the fuselage has a car hood type of panel that can be installed

raised to permit access to the nose avionics bay. I had already decided to omit

the well detailed boxes from the nose bay and instead inserted 5 grams of lead

shot, mainly as a precaution against the Gnat being a tail sitter, although the

main gear is so close to the trailing edge it might not need it. So the upper

nose hood was glued shut to conclude the basic build.

I had chosen the option with large areas of

dayglo, so after the transparencies were masked with Tamiya tape the whole

airframe was painted with Tamiya White Fine Surface primer applied from a rattle

can. Thanks to Airfix’s precise engineering, no filler was required and I could

proceed to painting the large areas of dayglo to the wings, nose and tail, using

Humbrol acrylic No 209 Dayglo red-orange. To my surprise this proved to be the

hardest part of the build. This particular paint has the heaviest pigment that I

have found in years and straight from the pot has a glue-like consistency. It

took me the best part of a day of trial and error, mixing and spraying,

variously trying to thin the paint with water and proprietary thinners,

until I found that about 20% Tamiya thinners was close

enough. Even so, the first attempt with this combination had runs all over the

finish, so it was stripped and redone. At last I had a dayglo that I considered

acceptable but there are still one of two areas that are patchy, so I had to

convince myself that this would be an accurate rendition of a paint finish that

soon weathered in service use. The bright areas were masked off and the main

airframe finished in Tamiya XF-16 Flat Aluminium – this is a silver that I

find gives an effe ctive

scale-like representation when later covered with a couple of hand brushed coats

of Future/Klear floor polish. The paintwork was finished with a squirt of XF-1

Flat Black to the masked off nose area and the tail pipe hand painted in Tamiya

X-32 Titanium Silver washed over with some dirty thinners to give a used effect.

The airframe was treated to two brushed coats of Future/Klear floor polish to

provide a base for the decals.

ctive

scale-like representation when later covered with a couple of hand brushed coats

of Future/Klear floor polish. The paintwork was finished with a squirt of XF-1

Flat Black to the masked off nose area and the tail pipe hand painted in Tamiya

X-32 Titanium Silver washed over with some dirty thinners to give a used effect.

The airframe was treated to two brushed coats of Future/Klear floor polish to

provide a base for the decals.

The

decals sheet is fully up to the current good standards to be found in an Airfix

kit, with bright colours and sharp printing and they went on easily, responding

well to Microscale’s Micro Sol and Micro Set decal solutions. There are nearly

100 decals to place, so a methodical plan is needed. I dealt first with the

under surfaces, then the top, then the sides, crossing each decal off the colour

plan in the instructions as I went along. The sheet includes extensive

stencilling and warning signs and a few of the tiniest proved too much for my

eyesight. The dayglo showed through the white of the roundels as a pink tinge,

so those under the wing were doubled up, using two spares from the kit’s sheet

and the upper wing insignia doubled by applying a pair from the decal dungeon.

I then

added the pre-painted wing tanks, horizontal tail and rudder. . The airframe

then received a further coat of Future/Klear to seal the decals in place

It

was now time to add the undercarriage and Airfix have done an excellent job in

moulding the complex gear legs essentially in one piece, providing positive

alignment and detailed notes in the instructions showing the angle of the main

legs. The legs were painted Light Grey and the wheels have White hubs with the

tyres picked out in Tamiya XF-85 Rubber Black.

All

that was left was attachment of the wing tip and nose landing light covers, the

gear doors and a few blade aerials to complete a very satisfying build.

This sort of product puts Airfix in the front rank of

kit producers in my opinion. It can be built straight from the box with a

satisfying result, yet provides scope for more refinement for those who need it.

It builds fairly easily, providing that the complex interior is

carefully assembled, bearing in mind the parts are so finely engineered that

even the thickness of a coat of acrylic paint, especially brush painted, can

interfere with a precise fit.

It was a pleasure to build and adds to what has

now turned out to be a short theme of jet trainers in my showcase. It keeps

company with my attempt at the same subject in 1:72 scale.

Highly recommended for its quality and bargain price.

The kit instructions; the Internet; my own photo

archives.

Frank Reynolds

February 2015

If you would like your product reviewed fairly and fairly quickly, please contact the editor or see other details in the

Note to

Contributors.

Back to the Main Page

Back to the Review

Index Page

Powered

by a Bristol Siddeley Orpheus engine of 4,700lb thrust, the little Gnat had

a wingspan of just 22ft 1in. and a length of 28ft 8ins. It was capable of

Mach 0.95. It was unconventional in size and appearance with its highly

loaded shoulder mounted wing and the fuselage mounted main undercarriage

served as the airbrakes. The tandem cockpit was a tight fit with the rear

seat occupant seemingly crammed into a notch in the leading edge of the wing

and hemmed in by the engine air intakes. It was also a mechanic’s nightmare

with equipment crammed into small spaces and it had needed the design of

special light weight ejector seats and miniaturised motors for the powered

flight controls.

Powered

by a Bristol Siddeley Orpheus engine of 4,700lb thrust, the little Gnat had

a wingspan of just 22ft 1in. and a length of 28ft 8ins. It was capable of

Mach 0.95. It was unconventional in size and appearance with its highly

loaded shoulder mounted wing and the fuselage mounted main undercarriage

served as the airbrakes. The tandem cockpit was a tight fit with the rear

seat occupant seemingly crammed into a notch in the leading edge of the wing

and hemmed in by the engine air intakes. It was also a mechanic’s nightmare

with equipment crammed into small spaces and it had needed the design of

special light weight ejector seats and miniaturised motors for the powered

flight controls. The

instructions run to twelve pages in an A4 booklet with full colour four-views

keyed to Airfix paint numbers and exploded views running to 38 stages of

construction,

The

instructions run to twelve pages in an A4 booklet with full colour four-views

keyed to Airfix paint numbers and exploded views running to 38 stages of

construction, Construction

begins with the cockpit area and a tub forms the floor and side walls, to which

the front and rear bulkheads are glued. The nose wheel bay is a well detailed

box that glues into an opening under the rear seat position. The front and rear

instrument panels/pedestals have raised dials, detailed with instrument decals

that shrank over the raised detail with the application of a little Micro Sol.

Separate rudder bars are provided for each seat position.

Construction

begins with the cockpit area and a tub forms the floor and side walls, to which

the front and rear bulkheads are glued. The nose wheel bay is a well detailed

box that glues into an opening under the rear seat position. The front and rear

instrument panels/pedestals have raised dials, detailed with instrument decals

that shrank over the raised detail with the application of a little Micro Sol.

Separate rudder bars are provided for each seat position. wn

inside the curves of the fuselage. Some time spent dry fitting before committing

to glue and joining the fuselage halves will pay dividends because the combined

parts are a very tight fit and even the thickness of a coat of paint can make a

difference.

wn

inside the curves of the fuselage. Some time spent dry fitting before committing

to glue and joining the fuselage halves will pay dividends because the combined

parts are a very tight fit and even the thickness of a coat of paint can make a

difference. By contrast, the adjoining trailing edge flaps are fixed in position and

alternative mouldings are provided or fixed or extended options.

By contrast, the adjoining trailing edge flaps are fixed in position and

alternative mouldings are provided or fixed or extended options. ctive

scale-like representation when later covered with a couple of hand brushed coats

of Future/Klear floor polish. The paintwork was finished with a squirt of XF-1

Flat Black to the masked off nose area and the tail pipe hand painted in Tamiya

X-32 Titanium Silver washed over with some dirty thinners to give a used effect.

The airframe was treated to two brushed coats of Future/Klear floor polish to

provide a base for the decals.

ctive

scale-like representation when later covered with a couple of hand brushed coats

of Future/Klear floor polish. The paintwork was finished with a squirt of XF-1

Flat Black to the masked off nose area and the tail pipe hand painted in Tamiya

X-32 Titanium Silver washed over with some dirty thinners to give a used effect.

The airframe was treated to two brushed coats of Future/Klear floor polish to

provide a base for the decals.