Airfix 1/72 Severn Class Lifeboat

| KIT #: | 07280 |

| PRICE: | Around €20.00 |

| DECALS: | Several options |

| REVIEWER: | Frank Spahr |

| NOTES: |

| HISTORY |

I won´t enter any discussions on the actual length of the

British coast

here. Benoit Mandelbrot has shown that the answer is

far more complex

than us mere ordinary minds would ever dream of. Suffice it to say that it is

-

very long,

especially for an island that size

-

very scenic and

beautiful and

-

very dangerous for

ships and boats,

-

especially in foul

weather (which is rarer than prejudice has it, but not uncommon either)

fibre reinforced composite hull, the Severns sport many

improvements and refinements learned from their predecessors, and from crews´

experiences. They can stay afloat with two of their five compartments flooded,

they have comprehensive navigational and communications equipment, their hull

form eases taking survivors on board, they are equipped with an inflatable boat

for operations in shallow waters, and their propulsion systems are designed for

exceptional ruggedness and maneouvrability. Their successors, the Tamar class,

have been designed for similar performance, yet slightly smaller to operate from

slipways.

fibre reinforced composite hull, the Severns sport many

improvements and refinements learned from their predecessors, and from crews´

experiences. They can stay afloat with two of their five compartments flooded,

they have comprehensive navigational and communications equipment, their hull

form eases taking survivors on board, they are equipped with an inflatable boat

for operations in shallow waters, and their propulsion systems are designed for

exceptional ruggedness and maneouvrability. Their successors, the Tamar class,

have been designed for similar performance, yet slightly smaller to operate from

slipways.

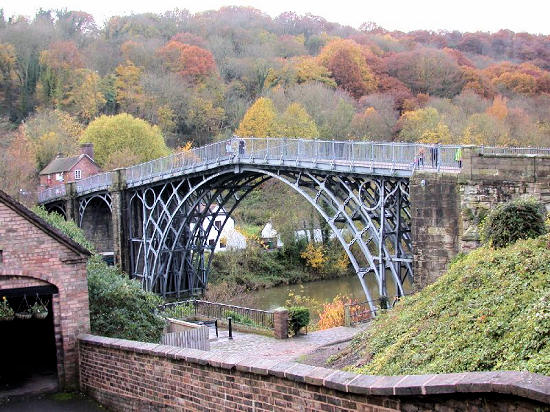

The class´ namesake, the river

Severn,

is the UK´s longest river at 220 miles. Its source is in Wales at Plynlimon, and

its mouth is the Severn Estuary at the Bristol Channel. The considerable tidal

range results in tidal waves occasionally strong enough to surf on – the

so-called

Severn Bore

. Amongst other points of interest, Ironbridge, a World Heritage Site and the

world´s first cast iron arched bridge, spans the Severn and is well worth

visiting.

Technical data

(Wikipedia)

|

Length |

55 ft 9

in (17 m) |

|

Beam |

18 ft 1 in

(5,5 m) |

|

Draught |

4 ft 6 in

(1,38 m) |

|

Displacement |

40 tons

(36,3 t) |

|

Propulsion |

2 × Caterpillar 3412 TA diesel engines, 1,250 hp (932 kW) each

|

|

Top speed |

25 kn (45

km/h) |

|

Range |

250 sm (460

km) |

|

Crew |

6 |

|

Capacity

when self righting /not self righting |

47 / 185 survivors |

| THE KIT |

The sturdy box is

packed tightly with four sprues of light grey and one of clear styrene. A

comprehensive instruction booklet with the cover page printed in colour and a

decal sheet (uncommonly in register) complete the contents. Sadly, the clear

parts are not packed separately and hence arrived with scratches. Apart from

that, they are basically clear and usable, yet a bit on the thick side.

Generally speaking, the styrene parts are well-molded, yet not free from some

annoying ejector pin marks, and not without sink marks in visible areas.

Compared with other recent kits, they do lack the crispness and fine detail

nowadays found in top manufacturers´ kits. Some parts suffer fro

The sturdy box is

packed tightly with four sprues of light grey and one of clear styrene. A

comprehensive instruction booklet with the cover page printed in colour and a

decal sheet (uncommonly in register) complete the contents. Sadly, the clear

parts are not packed separately and hence arrived with scratches. Apart from

that, they are basically clear and usable, yet a bit on the thick side.

Generally speaking, the styrene parts are well-molded, yet not free from some

annoying ejector pin marks, and not without sink marks in visible areas.

Compared with other recent kits, they do lack the crispness and fine detail

nowadays found in top manufacturers´ kits. Some parts suffer fro m unwieldy sprue

gates that make them hard to remove without damage. Another annoying feature is

that the parts are spread among the sprues virtually as arbitrarily as possible.

Due to this lack of foresight, the modeler will spend considerable time hunting

through the sprues for the next part needed. A more logical layout would be very

beneficial.

m unwieldy sprue

gates that make them hard to remove without damage. Another annoying feature is

that the parts are spread among the sprues virtually as arbitrarily as possible.

Due to this lack of foresight, the modeler will spend considerable time hunting

through the sprues for the next part needed. A more logical layout would be very

beneficial.

Speaking of logic,

the instructions should be taken with a sizable pinch of salt. Even though very

well done graphically, they are not always unambigious, and – most important to

me – the assembly sequence given is not what I would recommend. There are

several steps where sticking to the instructions will lead to frustration and

extra work. The idea of including some photos of

actual vessels into the

instructions is a good one. All colour callouts are given in Humbrol numbers

only, without any colour descriptions. That could be improved, both in giving

colour names as in giving equivalents for other manufacturers, as Humbrol is not

that widely available.

actual vessels into the

instructions is a good one. All colour callouts are given in Humbrol numbers

only, without any colour descriptions. That could be improved, both in giving

colour names as in giving equivalents for other manufacturers, as Humbrol is not

that widely available.

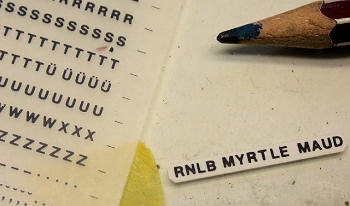

The decal set

contains code letters and station names for all active boats, yet no boat names,

just a generic nameplate decal with an “RNLB”. I learned that Airfix omitted the

names so as not to unduly privilege any one donor, as the boats are commonly

named after those who donated the money needed for their construction. Bottom

line is probably that inserting all the names would have resulted in an even

larger decal sheet as it is, so it looks like a cost-cutting measure to me.

Luckily, the decal sheet contains all the red-and-yellow trim plus extra

material – masking and spraying those lines would be a serious piece of work.

All in all, Airfix fans like me tend to have a different outlook on Airfix kits than most other modelers, with considerably more tolerance towards their flaws. To me, this is a very fine kit of an interesting subject, and I was more than happy when it appeared. The fact that Hornby/Airfix produces new kits is a hint at a prolonged lease of life for the company, and hence a promise of an ongoing supply of their not perfect, but always enjoyable kits to me.

| CONSTRUCTION |

Construction began

with looking for and receiving some useful hints on the Airfix Tribute Forum, a

place for hopeless Airfix addicts like me. The first issue was how to assemble

the multi-part hull as efficiently as possible. I was advised to divert from the

instructions

and first to assemble hull sides with the deck, and only then add

the bottom, but only after adding the bow thruster. That did work fine, yet

despite adding a stabilizing piece of sheet I ended up with a noticeable

instructions

and first to assemble hull sides with the deck, and only then add

the bottom, but only after adding the bow thruster. That did work fine, yet

despite adding a stabilizing piece of sheet I ended up with a noticeable

seam

running across the transom, needing careful filling and sanding. Generally

speaking, you will need to build this kit very cleanly, as the original vessels

are well-maintained and very clean – no weathering, at the utmost some little

signs of use are tolerable.

seam

running across the transom, needing careful filling and sanding. Generally

speaking, you will need to build this kit very cleanly, as the original vessels

are well-maintained and very clean – no weathering, at the utmost some little

signs of use are tolerable.

Another issue with

the hull is the waterline option. There are cut markings on the inside to

produce a waterline hull, but I would rather not recommend using them. Firstly,

because they make hull construction even fiddlier, as you end up with some very

iffy and finely tapered parts. Secondly,

because you will need a real waterline

hull only for a harbour diorama with absolutely calm water, and even then only

if the water base does not allow for cutting a recess to hide the hull in. Any

boat under way will show some part of the underwater hull, and the model´s

draught is not too excessive to be hid in a normal base plate. For those wanting

to build the vessel waterline the way Airfix suggests, there is a detailed

how-to on the Airfix Tribute Forum. Assembling the entire hull and only then

cutting away

because you will need a real waterline

hull only for a harbour diorama with absolutely calm water, and even then only

if the water base does not allow for cutting a recess to hide the hull in. Any

boat under way will show some part of the underwater hull, and the model´s

draught is not too excessive to be hid in a normal base plate. For those wanting

to build the vessel waterline the way Airfix suggests, there is a detailed

how-to on the Airfix Tribute Forum. Assembling the entire hull and only then

cutting away

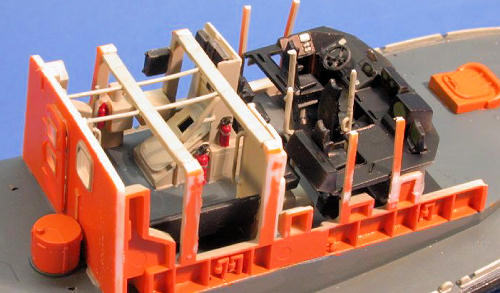

The next step after

assembling the hull was a diversion from instructions - I built the complete

outer shell of the superstructure as a subassembly, instead of building part of

it together with the interior. That enabled me to achieve a good fit of the

superstructure - both in itself and to the hull. Careful as I was in aligning

the parts, I needed quite some filling and sanding, which was done much more

easily on an empty shell than on a nearly completed model with clear parts in

place.

| COLORS & MARKINGS |

Having completed the

build so far, it was time for painting. I looked for the required colour shades

both in the instructions and while looking through images of actual vessels, and

ended up with a hodgepodge of both enamels and acrylics from my stocks. So my

underwater hull is painted WEM Antifouling Red, the rest of the hull is Revell

satin enamel Lufthansa blue, whilst the superstructure was painted Gunze Sangyo

Alert Orange from their Soya set. The deck was painted Xtracrylix RAF Dark Sea

Grey,  with the light grey railings and trimmings in JPS USAF Light Grey.

with the light grey railings and trimmings in JPS USAF Light Grey.

After the usual

priming and checking for flaws I used blue as the first coat on the hull. The

superstructure was “primed” in orange so as to render the paint as bright as

possible. I then masked the waterline, added the red hull paint, and then

applied several gloss coats using Future – essential for decaling.

The red and yellow trim decals worked rather nicely, even though they

might have benefited from a white underground. Sadly, I goofed on the next step,

as I used the white waterline decal instead of masking and painting. The decal

turned out to be not opaque enough, and the hull´s chine left a kink in the nice

waterline.

I had to repair that by masking and

painting – what I should have done in the first place. In hindsight, the best

approach would have been to paint the approximate area of the waterline white

first, then mask it using tape of appropriate width (with some corrections

around the chine), and then add the blue and red respectively. Having already

applied the red and yellow trim, that was not an option anymore. Well, you live

to learn.

The next goof had

already happened without my realizing it. I had sifted through the boat names

and numbers and had decided to call my Severn RNLB Myrtle Maud, as that reminded

me of Moaning Myrtle, a character from the Harry Potter novels. That vessel was

stationed at Arranmore. So, all the required hull and superstructure decals were

applied and sealed with Future. The nameplate was done using dry transfers and

looked quite nice to me. That is, until a friendly M2 regular informed me that I

had confused the boat´s code number. I had used 17-06, where it should have been

17-22. A short while and some colourful language later I started thinking hard.

I felt I would most surely botch the job of overpainting and replacing the ID

number on the hull, so I checked which boat was coded 17-06. Luckily, that boat

was stationed at Arran, so I would only have to overpaint part of the station

name, which looked much more attractive to me. The name, on the other hand, was

considerably longer, and could simple not be done with the dry transfers. So I

printed “RNLB Mr David Kirkaldy” in 5 point on my laser printer, cut it out and

glued the paper on the styrene plate. The hull and superstructure were then

sealed with clear satin acrylic, and the deck remaining in clear flat acrylic.

The next goof had

already happened without my realizing it. I had sifted through the boat names

and numbers and had decided to call my Severn RNLB Myrtle Maud, as that reminded

me of Moaning Myrtle, a character from the Harry Potter novels. That vessel was

stationed at Arranmore. So, all the required hull and superstructure decals were

applied and sealed with Future. The nameplate was done using dry transfers and

looked quite nice to me. That is, until a friendly M2 regular informed me that I

had confused the boat´s code number. I had used 17-06, where it should have been

17-22. A short while and some colourful language later I started thinking hard.

I felt I would most surely botch the job of overpainting and replacing the ID

number on the hull, so I checked which boat was coded 17-06. Luckily, that boat

was stationed at Arran, so I would only have to overpaint part of the station

name, which looked much more attractive to me. The name, on the other hand, was

considerably longer, and could simple not be done with the dry transfers. So I

printed “RNLB Mr David Kirkaldy” in 5 point on my laser printer, cut it out and

glued the paper on the styrene plate. The hull and superstructure were then

sealed with clear satin acrylic, and the deck remaining in clear flat acrylic.

| FINAL CONSTRUCTION |

As the nice interior can hardly be viewed after assembly, I did not go

overboard in detailing it, just painted the pieces in appropriate colours and

tried to make sure the superstructure would later fit over the interior. That

involved some sanding and still resulted in some gaps that had to be closed. The

kit transparencies also turned out to be an issue, as they were too thick for a

good fit of the superstructure to the hull. So they were replaced by pieces of

clear plastic cut from blister packs, glued with white glue. The final marriage

of hull and superstructure proved to be pretty exciting, and involved the use of

heavy tools to apply enough

pressure for an acceptable fit. Nonetheless some gaps had to be filled and

painted. Given the amount of work needed to fit the superstructure parts, I

would nonetheless proceed likewise in a

good fit of the superstructure to the hull. So they were replaced by pieces of

clear plastic cut from blister packs, glued with white glue. The final marriage

of hull and superstructure proved to be pretty exciting, and involved the use of

heavy tools to apply enough

pressure for an acceptable fit. Nonetheless some gaps had to be filled and

painted. Given the amount of work needed to fit the superstructure parts, I

would nonetheless proceed likewise in a future build - I would only leave out a

LOT of the interior parts.

future build - I would only leave out a

LOT of the interior parts.

These major steps

done, it was time to do the numerous small parts and subassemblies. The most

prominent of them, the inflatable boat and the crane, had their own issues. The

crane is molded in one piece, so it would need some major scratchbuilding to

depict it operative. So it was just cleaned up and painted. The inflatable lacks

detail and looks pretty clunky and empty. Having seen enough images of these

boats covered with a tarpaulin, I decided to use just that to avoid both any

further effort and embarrassment. After cleaning up and gluing the boat´s

engine, I made a cover using cigarette paper soaked in white glue. Painted in

orange, that looked good enough for me. The life raft canisters received straps

made from strips of Tamiya tape painted JPS dayglo orange. That was very easy

and looked pretty sharp. Tamiya tape also helped a lot on masking the bridge

windshield.

|

|

|

Getting the numerous

railings from their sprues was a major undertaking, and it did not end without

damage. But I was able to repair the parts and glue them to the boat, together

with the various other deck fittings. Some gaps in the railings were closed

using white glue. I should note that the painting guide is wrong re the

railings. Those at the stern are light grey, those on

using white glue. I should note that the painting guide is wrong re the

railings. Those at the stern are light grey, those on the superstructure are

white, and the rest is black, as the mast. Up there I digressed from building

OOB by replacing the clunky quadruple antenna with .4 mm brass wire. As for

construction sequence, I built from the center to the sides in order to minimize damage from handling. I also digressed from instructions as I first attached the

railings and only then the inflatable boat – it is much easier that way. The

searchlights were drilled out, painted silver inside and then covered with white

glue to simulate the lenses.

the superstructure are

white, and the rest is black, as the mast. Up there I digressed from building

OOB by replacing the clunky quadruple antenna with .4 mm brass wire. As for

construction sequence, I built from the center to the sides in order to minimize damage from handling. I also digressed from instructions as I first attached the

railings and only then the inflatable boat – it is much easier that way. The

searchlights were drilled out, painted silver inside and then covered with white

glue to simulate the lenses.

As always, the use of acrylics speeded up the build. Metalizer paints were used on the anchor and the pretty cool looking washboards at the transom; these were the last parts added before correcting any readily visible flaws and calling the project quits.

| CONCLUSIONS |

I did have fun

building it, and can recommend the kit to more experienced builders, though not

to beginners. You´ll need to judge yourself where to follow the instructions and

where not, and you have to be aware that this is not “shake and bake”, and

you´ll have to apply some modeling skills.

Already from the box, you´ll end up with a nice (and colourful!) model, and any scratchbuilders will have a great starting point for conversions and refinements. Some very exciting diorama possibilities spring to mind effortlessly, too!

| REFERENCES |

http://en.wikipedia.org/wiki/Severn_class_lifeboat

http://airfixtributeforum.myfastforum.org/index.php

December 2008

Copyright ModelingMadness.com

If you would like your product reviewed fairly and quickly, please contact the editor or see other details in the Note to Contributors.