Formaplane 1/72 Hawker Nimrod MR.2

| KIT #: | 3 |

| PRICE: | About $25.00 when new |

| DECALS: | None provided |

| REVIEWER: | Carmel J. Attard |

| NOTES: | Vacuformed plastic |

| HISTORY |

The Nimrod is a highly sophisticated and sensitive suite of systems used for reconnaissance and gathering electronic intelligence as well as ASW and Air /Sea search and rescue missions. The Nimrod has the ability to transit at high speed and then later in an operational area at a lower speed for long period of time and so makes it ideal suited for the task. The operating crew of 14 consists of two pilots and a flight engineer, two Weapons Systems officers and a WSO who is the sensor and communications co-coordinator. This is supported by a team of seven WSOs who supervise the aircraft’s acoustic processors, which monitor active and passive sonobuoys as well as manage a wide range of avionics and weapons systems that are essential to delivering Nimrod’s full capability.

The Nimrod is powered by four Rolls Royce Spey 250

turbofans, which gives a trust of 12,500 lbs each. It has a wingspan of 114’9’’,

a length of 126’9’’ and a maximum take off weight of 184,000 lbs. It has a

maximum endurance of 9.5 hours and can operate at a maximum height of 44,000 Ft.

The offensive weapons that are carried by t he Nimrod are the Sting Ray torpedoes

for use in the ASW role and he Harpoon missiles for the ASUW role. For SAR the

aircraft has a selection of air deliverable, multi-seat dinghies and survival

packs. For self-defence the aircraft can carry four AIM-9L sidewinders

air-to-air missiles carried on Pylons under the wings. The aircraft can carry in

excess of 200 sonobuoys internally of several different types, both active and

passive that are delivered via two unpressurised 6-buoy rotary launchers and two

pressurized single-shot launchers.

he Nimrod are the Sting Ray torpedoes

for use in the ASW role and he Harpoon missiles for the ASUW role. For SAR the

aircraft has a selection of air deliverable, multi-seat dinghies and survival

packs. For self-defence the aircraft can carry four AIM-9L sidewinders

air-to-air missiles carried on Pylons under the wings. The aircraft can carry in

excess of 200 sonobuoys internally of several different types, both active and

passive that are delivered via two unpressurised 6-buoy rotary launchers and two

pressurized single-shot launchers.

The Nimrod remains the only jet powered maritime patrol aircraft in military service and offers the advantages of speed and height in transit while capable of operating for long on-task periods. It offers stealth element in anti-submarine warfare, as the jet noise of the Nimrod is much less detachable than most propeller driven aircraft that makes discrete resonance during flight. The Nimrod has an endurance of 10 hours, which can be extended by air refueling during flight.

The early Nimrods MR1 began to use Luqa airfield in Malta in

July 1971 when it started to replace the Shackleton MR3 of 203 Squadron the last

of which departed in January 1972. They remained stationed on the island until

December 1977.This was towards the end of British forces using facilities on the

island. Nimrods continue to make visits to the island of Malta during the annual

international air show held on last weekend of September. Today the majority of

Nimrod’s tasking comes from the Maritime Headquarters at Northwood. Peacetime

work includes surface and sub-surface surveillance and maintenance of a one-hour

standby in support of the Air Rescue Coordination Centre, allocated at RAF

Kinless. Today, No 201,120 and 206 Squadrons operate Nimrods, all based at

Kinloss, in Morayshire, UK. This is also the home of No 42 Squadron. The Nimrod

MR2 will continue in service until it is replaced by the MRA4, which is expected

to enter service from 2007.

The early Nimrods MR1 began to use Luqa airfield in Malta in

July 1971 when it started to replace the Shackleton MR3 of 203 Squadron the last

of which departed in January 1972. They remained stationed on the island until

December 1977.This was towards the end of British forces using facilities on the

island. Nimrods continue to make visits to the island of Malta during the annual

international air show held on last weekend of September. Today the majority of

Nimrod’s tasking comes from the Maritime Headquarters at Northwood. Peacetime

work includes surface and sub-surface surveillance and maintenance of a one-hour

standby in support of the Air Rescue Coordination Centre, allocated at RAF

Kinless. Today, No 201,120 and 206 Squadrons operate Nimrods, all based at

Kinloss, in Morayshire, UK. This is also the home of No 42 Squadron. The Nimrod

MR2 will continue in service until it is replaced by the MRA4, which is expected

to enter service from 2007.

| THE KIT |

The Nimrod is a large vacform scale model released by Formaplane some years ago.

Today it is in circulation under a

different kit manufacturer: Aircraft in Miniature Limited, of Nuneaton,

Warwickshire, UK. The forgoing information relates to the early Formaplane kit

release where the vacform plastic was white and no decal and metal parts

were

supplied. The more recent release was in black plastic and though some of the

pictures that accompany the review are of a more recent release these were

exactly the same as the Formaplane kit with the main difference that originally

the kit appeared in white plastic.

were

supplied. The more recent release was in black plastic and though some of the

pictures that accompany the review are of a more recent release these were

exactly the same as the Formaplane kit with the main difference that originally

the kit appeared in white plastic.

The kit consisted of sheets of vacform plastic containing 16 parts for the fuselage, wings, tail planes, wheel doors, exhaust outlets, 3 fuselage bulkheads, four cockpit items, and 28 smaller vacform items for the undercarriage parts including vacform wheels. Parts from the clear Perspex sheet are the wing search light dome, cockpit windshield and two strips with impressions for the cockpit side windows. Incidentally for those who still have the Formaplane kit, the Aircraft in Miniature/ Transport wings also releases a set in white metal to cater for the undercarriage and oleo parts as well as refueling probe and other small items for the price of 7 Sterling.

Considering the huge size of the kit, which comes in a sturdy Formaplane type of

packing with a side view picture of the Nimrod in black and white, this is not

the type of kit for one to start on vacform modeling. It is the type that needs

some experience besides a lot of patience and one should have a go at smaller

vacform kits such as the type offered by a wide range from Esoteric, Rareplanes

and the like. It is recommended to acquire good scale plans and make good

reference to clear pictures of the Nimrod version that one desires to build from

websites as

www.airliners.net among others. This is so because there are visible

variations between a Nimrod and another as if equipment is updated constantly

and makes changes on the outside etc.

Considering the huge size of the kit, which comes in a sturdy Formaplane type of

packing with a side view picture of the Nimrod in black and white, this is not

the type of kit for one to start on vacform modeling. It is the type that needs

some experience besides a lot of patience and one should have a go at smaller

vacform kits such as the type offered by a wide range from Esoteric, Rareplanes

and the like. It is recommended to acquire good scale plans and make good

reference to clear pictures of the Nimrod version that one desires to build from

websites as

www.airliners.net among others. This is so because there are visible

variations between a Nimrod and another as if equipment is updated constantly

and makes changes on the outside etc.

| CONSTRUCTION |

The same

sequence of steps is applied for building vacform kits. Start by outlining the

plastic parts with a pointed permanent marker pen held at an angle of 45 degrees

to the flat surface. In so doing you will identify the kit part and surplus

backing sheet. Next is make a scribed line around the model parts using a sharp

pointed Exacto blade drawn forwards. Then snap off the unwanted plastic from

around the parts. It may take a couple of times scribing to get the plastic snap

off easily. The cut kit parts are then sanded on a 200 grit sanding paper, which

is fixed to a flat backing piece of wood. Being a large model, the Nimrod kit

parts would require a rectangular sanding area 2 ft x 6” in order to help you

sand evenly. Smaller areas of sanding paper are only

recommended for smaller

models. The plastic parts are moved in a gentle circular rubbing motion until

the sanding edge reaches the permanent marker line. All the components are

treated in this manner. Other items such as main wing parts and tail planes must

be sanded so the edges form a natural contour, i.e. sanded to a very sharp thin

edge. One of the weak points would be if you leave a thick trailing edge that

spoils a nicely done model. The vacform kit also contains some imperfections on

the plastic arising from tiny holes on t the models mould through which the

vacuum is created when the model is made. These are sanded off and filled with

putty as needed.

recommended for smaller

models. The plastic parts are moved in a gentle circular rubbing motion until

the sanding edge reaches the permanent marker line. All the components are

treated in this manner. Other items such as main wing parts and tail planes must

be sanded so the edges form a natural contour, i.e. sanded to a very sharp thin

edge. One of the weak points would be if you leave a thick trailing edge that

spoils a nicely done model. The vacform kit also contains some imperfections on

the plastic arising from tiny holes on t the models mould through which the

vacuum is created when the model is made. These are sanded off and filled with

putty as needed.

Having the parts cut and brought to size it is then the turn to attend to each part. Starting with the fuselage, where the windows needs to be cut to fuselage sides and cockpit area using a sharp modeling knife and a set of files to shape each window according to the outline printed on kit part half. Small air intakes are opened and when this stage is complete the attention is turned to the pilot and crew office, using the supplied parts already shaped accordingly and given detail treatment and paintwork. Bulkheads are cut, glued and secured in place. Some dry fitting and checking is carried out in order to ensure that fuselage halves are not over sanded. It will help if at this stage to glue small tabs of plastic on alternate sides inside the edges of the two fuselage halves. This will give the glue more holding surface.

Bearing in mind that this is a big

model then one have to ensure that the vertical and horizontal axis of the model

from being twisted during joining and building process. This is essential during

joining of wings and horizontal stabilizers to the fuselage and when mounting

the landing gear. The wings are quite sizeable, and when the undercarriage bay

is cut, wing spars are added and the undercarriage bay is boxed using scrap

plastic strips cut to fit to sides. Small dowels made from sprue are added to

tail planes and main wing root ends. A jig made from thick cardboard is useful

to maintain the correct alignment and anhedral during joining process.

Bearing in mind that this is a big

model then one have to ensure that the vertical and horizontal axis of the model

from being twisted during joining and building process. This is essential during

joining of wings and horizontal stabilizers to the fuselage and when mounting

the landing gear. The wings are quite sizeable, and when the undercarriage bay

is cut, wing spars are added and the undercarriage bay is boxed using scrap

plastic strips cut to fit to sides. Small dowels made from sprue are added to

tail planes and main wing root ends. A jig made from thick cardboard is useful

to maintain the correct alignment and anhedral during joining process.

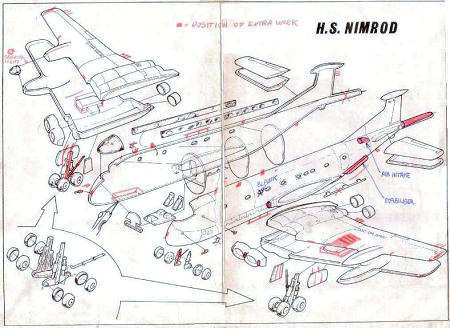

The

cockpit parts supplied with the kit are very basic if also of the wrong shape.

The floor and instrument panel are first fixed in place. Control sticks are

added and crew figures added to the reshaped seats. Rudder pedals and other side

instruments are added to the cockpit. It is not possible to emphasize on cockpit

detailing since much of it will be hidden but the parts added are correctly

painted in the respective colour. Cockpit area was painted light grey with

touches of darker grey and black. The items were glued to one fuselage half.

Nose weight was added in a boxed compartment and glued to a forward part of the

nose area. Wheel well detail is then added and finally the fuselage halves are

joined together and held with masking tape strips. Fitting the clear canopy

Perspex was left to a later stage. The kit instructions contain an exploded view

of the kit parts. The ones I marked in red are the items that I had to add to

the kit or are replaced. The progressive assembly of the Nimrod model followed

three phases: Correction of the kit parts, conversion of the kit into an early

Mk 2 and extra work done to the kit.

The

cockpit parts supplied with the kit are very basic if also of the wrong shape.

The floor and instrument panel are first fixed in place. Control sticks are

added and crew figures added to the reshaped seats. Rudder pedals and other side

instruments are added to the cockpit. It is not possible to emphasize on cockpit

detailing since much of it will be hidden but the parts added are correctly

painted in the respective colour. Cockpit area was painted light grey with

touches of darker grey and black. The items were glued to one fuselage half.

Nose weight was added in a boxed compartment and glued to a forward part of the

nose area. Wheel well detail is then added and finally the fuselage halves are

joined together and held with masking tape strips. Fitting the clear canopy

Perspex was left to a later stage. The kit instructions contain an exploded view

of the kit parts. The ones I marked in red are the items that I had to add to

the kit or are replaced. The progressive assembly of the Nimrod model followed

three phases: Correction of the kit parts, conversion of the kit into an early

Mk 2 and extra work done to the kit.

Correcting the kit parts included the reshaping and repositioning ¾” forward of

the tail bumper which is now enlarged. The MAD boom was grossly oversize

and was replaced with a scratch build one made from a disused wooden brush stick

shaped and cut to size. The leading edge area close to fuel tank and searchlight

was reshaped with a file. Nose area was also rebuilt and filed to a more

acceptable shape. Fuel dampers were added three on each trailing edge using

stretch sprue pieces.

Correcting the kit parts included the reshaping and repositioning ¾” forward of

the tail bumper which is now enlarged. The MAD boom was grossly oversize

and was replaced with a scratch build one made from a disused wooden brush stick

shaped and cut to size. The leading edge area close to fuel tank and searchlight

was reshaped with a file. Nose area was also rebuilt and filed to a more

acceptable shape. Fuel dampers were added three on each trailing edge using

stretch sprue pieces.

The

conversion into an early Mk2 mainly consisted in the following alterations:

Adding a large air intake to the aft compartment, port side only, adding a large

ventral stabilizer. Blanking one window to port side. Adding a series of

antennae to upper fuselage. One should note that there was a variety of window

arrangements fitted to different Nimrods and therefore one should make

correct

study of the particular Nimrod that one is building by careful study of photos

of the real aircraft. An additional six antennae made from plastic card were

joined to various localities on the roof of the fuselage. Two pitot tubes were

added to starboard fuselage side and another added to port side near crew cabin.

There is a small air intake located between the two larger engine air intakes.

This was filed to shape and stretch sprue brackets cut to small lengths added

across the intakes. The cockpit windshield was now added to the fuselage and the

joint faired over with putty and sanded to a smooth finish. Windscreen wipers

were added. A tiny aerial made from thin steel wire was added to end of tail

boom. The exhaust outlets also needed careful cutting and shaping before being

joined to the wing trailing root area.

correct

study of the particular Nimrod that one is building by careful study of photos

of the real aircraft. An additional six antennae made from plastic card were

joined to various localities on the roof of the fuselage. Two pitot tubes were

added to starboard fuselage side and another added to port side near crew cabin.

There is a small air intake located between the two larger engine air intakes.

This was filed to shape and stretch sprue brackets cut to small lengths added

across the intakes. The cockpit windshield was now added to the fuselage and the

joint faired over with putty and sanded to a smooth finish. Windscreen wipers

were added. A tiny aerial made from thin steel wire was added to end of tail

boom. The exhaust outlets also needed careful cutting and shaping before being

joined to the wing trailing root area.

| COLORS & MARKINGS |

All

undersurfaces were airbrushed in two coats of Humbrol light aircraft grey while

the upper surfaces were coated in Hemp, which included an area extended under

the leading edge and wing tips. At the time I built the kit I used Gloy

Authentic Aircraft paints. Freshly painted Hemp consisted of four parts A3775

and one part A333. Later hemp colours tended to fade with weathering and tended

to appear slightly lighter in shade on Nimrods after a time. Other smaller

details as antennae of various shape were black and others white. No decals are

supplied with the kit and I had to sort these out from a variety of sources. The

upper wing roundels came from a Model Decal Lightning sheet, and for the

fuselage roundel I used one from a Matchbox Hunter sheet. The serial numbers

were sorted out from a sheet issued by Model Decals. The black trim at the bomb

bay came from Scale Master black strip sheet. I have used Micro setting solution

for all the decal applications. The completed model was finally given a semi

matt finish using 50:50 mix of Micro Matt and Micro Gloss varnish.

All

undersurfaces were airbrushed in two coats of Humbrol light aircraft grey while

the upper surfaces were coated in Hemp, which included an area extended under

the leading edge and wing tips. At the time I built the kit I used Gloy

Authentic Aircraft paints. Freshly painted Hemp consisted of four parts A3775

and one part A333. Later hemp colours tended to fade with weathering and tended

to appear slightly lighter in shade on Nimrods after a time. Other smaller

details as antennae of various shape were black and others white. No decals are

supplied with the kit and I had to sort these out from a variety of sources. The

upper wing roundels came from a Model Decal Lightning sheet, and for the

fuselage roundel I used one from a Matchbox Hunter sheet. The serial numbers

were sorted out from a sheet issued by Model Decals. The black trim at the bomb

bay came from Scale Master black strip sheet. I have used Micro setting solution

for all the decal applications. The completed model was finally given a semi

matt finish using 50:50 mix of Micro Matt and Micro Gloss varnish.

| CONCLUSIONS |

This was

a large vacform kit that I had no patience to wait for one of the kit

manufacturers to release it by injection moulding. With the Airfix Nimrod

supposedly due to be released soon, it is hoped that other versions of the

aircraft can eventually be built (so long there is empty space left on the

display shelves}.

This was

a large vacform kit that I had no patience to wait for one of the kit

manufacturers to release it by injection moulding. With the Airfix Nimrod

supposedly due to be released soon, it is hoped that other versions of the

aircraft can eventually be built (so long there is empty space left on the

display shelves}.

October 2006

Copyright ModelingMadness.com. All rights reserved. No reproduction in part or in whole without express permission from the editor.

If you would like your product reviewed fairly and fairly quickly, please contact the editor or see other details in the Note to Contributors.