Fondierie Miniatures 1/48 CM-170 Magister

|

KIT # |

6011 |

|

PRICE: |

$45.00 |

|

DECALS: |

Four aircraft |

|

REVIEWER: |

|

|

NOTES: |

Bring your Dremel Tool and face mask - you're going to need it. |

|

HISTORY |

Etablissments Fouga et Cie was founded in 1936 by two engineers - R. Costello and P. Maubassinin, who were also sailplane enthusiasts - to design and produce sailplanes. Following the end of the Second World War, the company became involved in the design and development of a variety of light jet aircraft, including the CM-8R-13 Sylphe in 1949, the CM-8R-9.8 Cyclope in 1951 and the CM-8R-8.3 Midjet. As part of this effort, they also tested jet engines. The CM-88 Gemeaux was created as a testbed for the "Pimene," "Marbore" (I&II), and "Aspin" (I&II) engines.

The CM-170 was designed in response to a French Air Force specification issued in 1950 for a two-seat jet trainer. The resulting all-metal twin engine aircraft was distinguished by the 'V' or 'butterfly' tail structure utilized in previous designs. The first of three prototypes flew on July 23, 1952. The first of ten pre-production aircraft ordered in 1953 followed on July 7, 1954. Following a successful test program, the Armee de l'Air ordered 95 aircraft; the first of these was rolled out on February 29, 1956 and given the name "Magister," latin for "teacher."

The "Magister"

provided a low-cost airframe that was economical to operate, while providing

all the performance needed to introduce a new pilot to the world of jet

aviation. With the success of the airplane in French service, production of

the CM-170 was carried out in France, and under license in Germany by Flugzeug

Union Sud, in Finland by Valmet OY, and in Israel by IAI.

The "Magister"

provided a low-cost airframe that was economical to operate, while providing

all the performance needed to introduce a new pilot to the world of jet

aviation. With the success of the airplane in French service, production of

the CM-170 was carried out in France, and under license in Germany by Flugzeug

Union Sud, in Finland by Valmet OY, and in Israel by IAI.

The CM-175 "Zephyr," a naval version with arrester hook, was first flown May 30, 1959. The CM-170-2 - more powerful version - appeared in 1961. Total French production amounted to 916 aircraft, first by Fouga, then Potez, then Aerospatiale as the French aerospace industry changed.

The CM-170 "Magister" served with the Air Forces of Austria, Belgium, Brazil, Cambodia, Congo, Finland, France, Germany, Israel and Lebanon. Reworked CM-170S have been operated by Algeria, Bangladesh, Cameroon, Guatemala, Ireland, Rwanda, Salvador, and Senegal. 60 of the 88 Israeli-built "Magisters" were converted for ground-attack and used in the Six-Day War in 1967.

The CM-170 is perhaps best-known to aviation enthusiasts as the aircraft used by national aerobatic teams such as the Red Devils of Belgium, the Patrouille de France, and the teams of Germany and Ireland. The six Super Magisters (CM-170-2) flown by the Irish Air Corps were among the last in service, exceeded in Europe by the eleven Magisters of the Force Arienne Belge.

Many of the

European-operated Magisters were finally replaced by the Dassault-Breguet/Dornier

Alpha Jet, or the British Aerospace Hawk, though the aircraft served in a

military role with various smaller air forces into the 1990's.

Many of the

European-operated Magisters were finally replaced by the Dassault-Breguet/Dornier

Alpha Jet, or the British Aerospace Hawk, though the aircraft served in a

military role with various smaller air forces into the 1990's.

With a maximum speed of 410 mph, a climb rate of 3,150ft/min, a ceiling of 33,300ft and a range of 775miles, powered by the (comparatively) fuel-efficient Turbomeca Marbore IIA, and excellent flight characteristics, the CM-170 "Magister" has become a popular private aircraft with the international warbird jet fraternity. Out at Chino, there are four in active operation, while there are another four still in French Air Force markings on the ramp awaiting buyers. I have had the good fortune to get two flights in the back seat of one of the Chino Magisters; its performance is close to what I have experienced in a P-51, without the engine racket - though they are very screechingly-noisy if you are on the field when they taxi out. The airplane has finger-light controls and is very responsive, all-in-all a lot of fun to fly.

|

THE KIT |

The only other "Magister" kits I am aware of is a 1/72 kit issued in the 1970s by Airfix, which I remember as being very nice for its scale and period of production, and at least one 1/48 vacuform - though I cannot remember who released it. When this kit was released in 2000 by Fonderies Miniatures, it became the first kit by that company that I built. You should take the fact that, of the three: Magister, Mystere IVA and Vautour IIN I bought it is the last one I have completed as a comment about the difficulty of the kit in construction.

The kit is

multi-media, with most airframe components made of a very thick grey plastic

with a finished surface resembling the face of the moon and requiring a lot of

sanding-down to get smooth, a resin cockpit and other small details,

poorly-molded white metal detail parts such as seats and controls with lots of

flash, photo-etch small details and instrument panels, and two vacuform

canopies that turn out to be "just" too large for the kit. The kit provides

decals for two French Air Force aircraft, a CM-170 of the Patrouille de

France, and a camouflaged aircraft used by the Algerian Air Force.

Max

Decals has also released a sheet that provides markings for CM-170s used by

the Irish Air Corps, the Finnish Ilmavoimat, the Israeli Air Force, and

several African countries.

The kit is

multi-media, with most airframe components made of a very thick grey plastic

with a finished surface resembling the face of the moon and requiring a lot of

sanding-down to get smooth, a resin cockpit and other small details,

poorly-molded white metal detail parts such as seats and controls with lots of

flash, photo-etch small details and instrument panels, and two vacuform

canopies that turn out to be "just" too large for the kit. The kit provides

decals for two French Air Force aircraft, a CM-170 of the Patrouille de

France, and a camouflaged aircraft used by the Algerian Air Force.

Max

Decals has also released a sheet that provides markings for CM-170s used by

the Irish Air Corps, the Finnish Ilmavoimat, the Israeli Air Force, and

several African countries.

All this great "production value" results in a lot of "interesting modeling" (as in "May you live in interesting times") during construction, with the atmosphere over the workbench on occasion turning a deep shimmering purple with lightning bolts exploding out of it, as the modeler runs into the next roadblock to successful completion of the project; this is a model for which you should insure that any small children in the vicinity are out of earshot unless you want to add many new words and sounds to their vocabulary.

|

CONSTRUCTION |

After sawing the

plastic parts off the very thick injection sprues, the first thing I got to

discover that the resin cockpit - which comes as a "tub" that is supposed to

fill the forward fuselage and provide sufficient weight to make the model a

nose-sitter - is overall about 1/16 inch greater in diameter than the interior

dimensions of the fuselage! The result was that the model went back into the

box for seven or eight months, until I was fortunate enough to receive a Dremel Tool as a Christmas present from that mistress of modeling mastery,

Candice Uhlir.

After sawing the

plastic parts off the very thick injection sprues, the first thing I got to

discover that the resin cockpit - which comes as a "tub" that is supposed to

fill the forward fuselage and provide sufficient weight to make the model a

nose-sitter - is overall about 1/16 inch greater in diameter than the interior

dimensions of the fuselage! The result was that the model went back into the

box for seven or eight months, until I was fortunate enough to receive a Dremel Tool as a Christmas present from that mistress of modeling mastery,

Candice Uhlir.

After sawing away with a razor saw to take off the solid resin below the cockpit floor, I pulled out the Dremel Tool and dremeled-out the fuselage interior, then dremeled-down the resin cockpit, until eventually the cockpit could be installed and the fuselage halves would meet along the centerline. This meant there wasn't the weight for the required nose-sit. I solved this by taking some lead weights, cutting them into smaller pieces and then hammering them into thinner pieces, and slipping them into the very-confined space below the cockpit floor, with some put into the extreme nose - which is supposed to be the wheel well (just don't look inside there); the result was a definite nose-sit when completed.

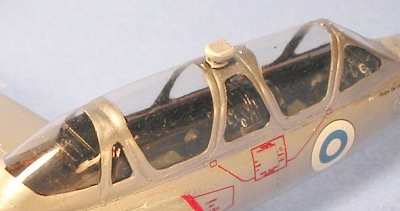

After cleaning up

the various white metal parts, I managed to get an acceptable-looking cockpit,

which I was very glad to paint overall flat black - which hides what is likely

a multitude of sins, but looks like a cockpit when viewed through the closed

canopy.

After cleaning up

the various white metal parts, I managed to get an acceptable-looking cockpit,

which I was very glad to paint overall flat black - which hides what is likely

a multitude of sins, but looks like a cockpit when viewed through the closed

canopy.

After assembling the wings and tail surfaces, I drilled them out so that I could use some plastic rod to make better attachment surfaces, and glued them in their respective positions. When this was all set up, I pulled out the sanding sticks and started in on "the surface of the moon," graduating to ever more fine-grit sandpaper as I ground things down to an acceptable surface. I then applied Mr. Surfacer to all the joints and sanded them smooth - a process that took several applications of Mr. Surfacer to accomplish. When this was finally complete, and I had sanded everything with extra-fine-grit paper, I then used some automotive Turtle Wax (it's thick), over the entire model, polishing it down so a natural metal finish could eventually be applied.

I then went after the cockpit canopy. After Futuring it, and cutting and trimming it to get something that seemed to fit, I attached it with cyanoacrylate, puttied the joint, sanded that down, then polished that area again.

(This all sounds very straightforward, but - as with the Vautour - I am describing various separate sessions on each step, separated by periods of weeks to months with the model stuffed in its box and stuck in a back corner of the work area while I did my best to forget this little monster existed)

I finally decided to either finish it or throw it away, so with a final burst of energy I managed to attach all the various resin and white metal detail bits to the external airframe, and assemble the landing gear and attach it. Finally! It was time for paint.

|

CAMOUFLAGE & MARKINGS |

Painting:

I found one Finnish

airplane on the Max Decals sheet that was in natural metal without any high-viz

panels on it, and that one became the final product since it was the easiest

scheme. (Coward! A real modeler would have done the da-glo panels.

:o) Ed)

I found one Finnish

airplane on the Max Decals sheet that was in natural metal without any high-viz

panels on it, and that one became the final product since it was the easiest

scheme. (Coward! A real modeler would have done the da-glo panels.

:o) Ed)

I was quite happy to discover, after applying a coat of gloss black overall, that there were only a few small areas that required further sanding and smoothing. With that out of the way, I shot the model with an overall finish of SnJ Aluminum, applied in several misting coats. I used some Testors ModelMaster metalizer colors around the jet exhaust and a few other panels, and painted the intakes red.

Decals:

The Max Decals are very thin, and have to be handled with care. That said, they go down without problems. Once they were set and dry, I washed the whole model, then applied a light coat of sealer to protect the finish and decals.

|

FINAL CONSTRUCTION |

Since I had already attached the landing gear, I painted the wheels with Gunze "Tire Black" and attached the vacuform nose light cap. I unmasked the canopy and...

My God! It actually looked like a Fouga CM-170 "Magister"!! Will wonders never cease?

|

CONCLUSIONS |

Scott says that any modeler who completes one of these French limited-run kits deserves a medal. I'll take something big and brassy and shiny with a bright scarlet ribbon, sort of a 21st Century "Blue Max," please.

If you would like your product reviewed fairly and fairly quickly, please contact the editor or see other details in the Note to Contributors.