Eduard 1/72 Sopwith HS

| KIT #: | 7201 |

| PRICE: | $10 at a swap meet |

| DECALS: | |

| REVIEWER: | Peter Burstow |

| NOTES: | Simple conversion |

| HISTORY |

Designed by Harry Hawker and Fred Sigrist, the Sopwith SS, nicknamed “Tabloid”,

first flew on 27th November 1913, as a side-by-side two seat sporting aircraft.

Powered by an 80 h.p. Gnome rotary engine, it's performance was so good that a

single seat version was ordered for the R.F.C. and the R.N.A.S. It was one of

the very first mass produced military aircraft.

In February 1914, T. O. M. Sopwith started planning a float-plane version to

compete in the upcoming Coupe d'Aviation Maritime Jacques Schneider, later known

as the Schneider Trophy race, to be held at Monaco on 20th April that year.

Fred

Sigrist made only minor changes to the SS, adding a small triangular fin and

enlarging the rudder. A 100 h.p. 9 cylinder Gnome Monosoupape (one valve per

cylinder) engine was fitted, the first such engine imported into Britain.

Floatation gear was designed by Sidney Burgoyne, a large central float was

added, with small floats under the wings, and a tail float.

Fred

Sigrist made only minor changes to the SS, adding a small triangular fin and

enlarging the rudder. A 100 h.p. 9 cylinder Gnome Monosoupape (one valve per

cylinder) engine was fitted, the first such engine imported into Britain.

Floatation gear was designed by Sidney Burgoyne, a large central float was

added, with small floats under the wings, and a tail float.

The aircraft, called the Sopwith HS, was completed on 31 March 1914, and

transported to the Hamble river near Southampton. Harry Hawker, Sopwith's usual

test pilot, was in Australia trying to sell more Tabloids, so Howard Pixton, who

had joined the company a few weeks before, attempted the first flight on the

evening of April 1st. On opening the throttle, the HS nosed in and tipped onto

it's back, dumping Howard into the river. After waiting for the tide, the

aircraft was recovered at 2 o'clock the next morning and returned to the factory

for repair

Running out of time, Sigrist and Burgoyne redesigned the float system for twin

floats. The large float was sawn in two, and sealed, the wing floats were

removed. A simple strut arrangement was used to support the floats. Early in the

morning of the 7th of April, the aircraft was taken to the Thames, where brief

flotation tests were done. Flying as prevented by Thames Conservancy river

wardens, an early attack by greenies. The next morning the aircraft was taken

further down river, outside the Thames Conservancy area, and a brief test flight

was completed, the only problem being a misfiring engine. The aircraft was then

returned to the factory, dismantled and packed for shipping to Monaco.

The Sopwith team arrived at Monaco on the 15th of April, the aircraft was

released by customs the next day and quickly assembled. The Gnome engine was

rusted from it's swim a few weeks before, and needed a thorough overhaul. The

aircraft was ready to fly on the 18th, but rough weather led to a postponement

until the 19th, the day before the race.

After the test flight the propeller was changed, and an extra six gallon fuel

tank was fitted. Some of the chassis rigging wire was replaced, as it had

stretched. This is very obvious in one of the photos of the HS on the beach at

Monaco, the float rigging wires are very slack.

The

race, really a time trial, was held over a 10km triangular course, 28 laps being

required. The first competitors started just after the gun at 8am. Pixton

started at about quarter past the hour. The Sopwith HS had no problems

completing the course, other than the engine starting to misfire on the 15th

lap, so was running on 8 cylinders for almost half the way. Pixton completed the

course in a 2 hours and 39 seconds, with an average speed of 139.6 kph, (86.78

mph) which included two compulsory downwind touchdowns. He then did another two

laps of the course, setting a float-plane speed record over a 300km distance.

The

race, really a time trial, was held over a 10km triangular course, 28 laps being

required. The first competitors started just after the gun at 8am. Pixton

started at about quarter past the hour. The Sopwith HS had no problems

completing the course, other than the engine starting to misfire on the 15th

lap, so was running on 8 cylinders for almost half the way. Pixton completed the

course in a 2 hours and 39 seconds, with an average speed of 139.6 kph, (86.78

mph) which included two compulsory downwind touchdowns. He then did another two

laps of the course, setting a float-plane speed record over a 300km distance.

Of the other competitors, Lord Carberry, flying a Deperdussin, only completed a

single lap. Gabriel Espanet in a Nieuport dropped out after 17, and Adrien

Levasseur, also flying a Nieuport finished on lap 18. The only other competitor

to finish was the Swiss Ernest Burri, flying a Franco-British Aviation Co. FBA

type A flying boat. He took an hour and 23 minutes longer than the Sopwith to

complete the course, stopping for fuel on lap 24 didn't help.

The result was a emphatic win for the Sopwith HS floatplane. When Jacques

Schneider congratulated Howard Pixton, he offered a glass of champagne, Pixton

declined, saying he would prefer a Bass (beer).

Sopwith went on to build 160 “Schneider” float-planes, based on the HS, for the

R.N.A.S., some of which were still serving in 1918.

A Sopwith Schneider, re-engined with a 450h.p. Cosmos Jupiter radial, was

entered in the 1919 Schneider Trophy race. Conditions were so bad, with thick

fog, that Harry Hawker did not start the race.

| THE KIT |

Released by Eduard, kit 7201 represents the military version of the “Tabloid”

float-plane, known unofficially as the Sopwith Schneider. Judging by the kit

number, this might be the first 1/72 kit Eduard produced.

There is

a single moulded sprue in soft grey plastic, with 20 parts, crudely moulded with

large gates, lots of flash and stray lumps and bumps. An alternate fin and

rudder part is supplied to allow a late built “Schneider”. There is a very

exaggerated hills and valleys fabric effect on the wings, but little other

detail.

There is

a single moulded sprue in soft grey plastic, with 20 parts, crudely moulded with

large gates, lots of flash and stray lumps and bumps. An alternate fin and

rudder part is supplied to allow a late built “Schneider”. There is a very

exaggerated hills and valleys fabric effect on the wings, but little other

detail.

Somewhat making up for the horrible plastic parts, there are three frets of

etched brass, with detailing parts for the cockpit, engine, and various other

bits. One fret has all the struts. A small film sheet has an instrument panel,

which is to be laminated to the brass part.

The decal sheet, printed by Propagteam, has 14 roundels in different sizes and

styles, two different fin flashes and four sets of serials. The decals are

bright and in good registration, though the colours seem a little transparent. I

didn't use them, so cannot comment on their effectiveness.

Some minor changes are needed to convert the model into a HS. Fill the aileron

gaps and gun port on the wings, change the shape and mounting of the tail-float,

alter the float struts, and make new markings.

| CONSTRUCTION |

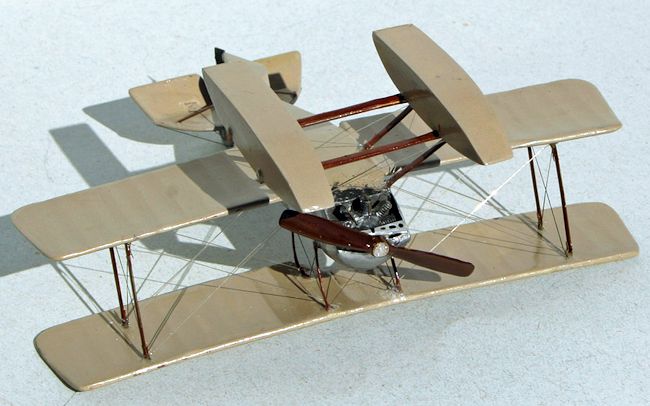

Next

step was the engine, the plastic lump needed a lot of clean up before it was

usable, then I added two brass bosses, and 9 of the 18 supplied tiny brass

push-rods. Only one per cylinder, as the engine is a Monosoupape. The

instructions got this a bit wrong. Some painting and dry brushing with Mr Metal

Color, Aluminium and Iron, brought out the detail, most of which is completely

hidden by the unusual bull-nosed cowling, which has a badly fitting brass plate

on it's underside.

Next

step was the engine, the plastic lump needed a lot of clean up before it was

usable, then I added two brass bosses, and 9 of the 18 supplied tiny brass

push-rods. Only one per cylinder, as the engine is a Monosoupape. The

instructions got this a bit wrong. Some painting and dry brushing with Mr Metal

Color, Aluminium and Iron, brought out the detail, most of which is completely

hidden by the unusual bull-nosed cowling, which has a badly fitting brass plate

on it's underside.

The wings needed a bit of work. First filling the engraved ailerons, the

Tabloids and early Schneiders were wing warpers, and didn't have any ailerons.

The instructions suggest binding the gaps for an early version. I filled the gun

port in the upper wing with a small piece of card, and more putty. The wings

then got a good sand to reduce the 'hills and valleys'. The wings probably only

looked that saggy when the plane was recovered from the Hamble. The lower wing

was a poor fit to the fuselage, needed a bit of hack and slash to get it to fit,

and a lot of filling to cover the resulting gaps.

I removed the elevator from the tailplane, and re-attached it hanging down. The

pictures of the HS when not flying, show the elevator drooping. The tailplane

and early version fin was then attached to the fuselage, with a bit more filling

needed.

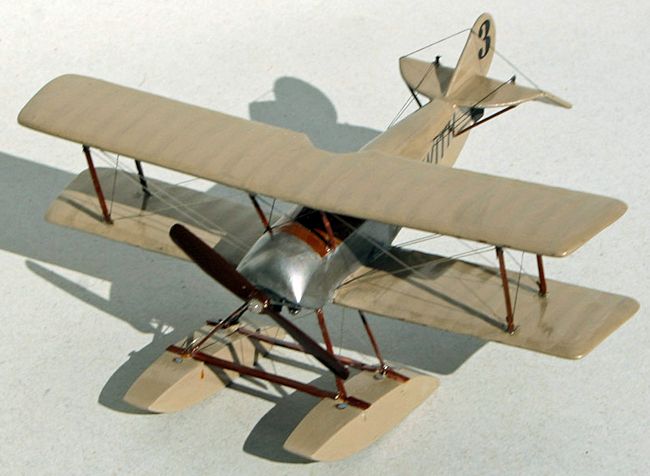

I assembled the main and tail float halves, the fit on the main floats was not

good, with a large hollow needing filling along one of the joints. The tail

float was very much the wrong shape, photos and plans of the HS show the float

is tear-drop shaped in plan, and rectangular in elevation. A lot of sanding, and

some card and filler, fixed that. The tail float was then attached directly to

the fuselage.

| COLORS & MARKINGS |

| FINAL CONSTRUCTION |

Drilled

out holes for the brass struts, there were only tiny dimples moulded into the

wing surface. Bent and added the inter-plane struts, then the upper wing. While

it was flexible, I aligned it with the plans to get the gap and stagger right.

The cabane struts were too short, by about 4mm, so were replaced with thin

plastic strip.

Drilled

out holes for the brass struts, there were only tiny dimples moulded into the

wing surface. Bent and added the inter-plane struts, then the upper wing. While

it was flexible, I aligned it with the plans to get the gap and stagger right.

The cabane struts were too short, by about 4mm, so were replaced with thin

plastic strip.

Assembled the main float structure, again using the etched brass struts

provided. The kit supplied 'N' struts for the main legs, correct for a

Schneider, but not for the HS, so the diagonal leg was cut away. The slots in

the main floats were then filled and smoothed over, hiding the joint. The float

assembly was joined to the fuselage and aligned while still flexible.

Just about to start rigging, when I noticed that the HS, unlike the later

Schneiders, had the float cross struts proud of the float, not recessed. Looks

just like a plank laid across the top. Chipped off the paint and superglue, then

fitted an Evergreen strip that looked about the right size.

The brass struts looked very two-dimensional so I ran a bead of medium thickness

slow superglue down both sides of each strut. Surface tension was enough to pull

the bead into a reasonable shape, thin along the edges and thicker down the

middle. Painted the struts Tamiya XF-68 NATO brown, then gave them a coat of

X-26 clear orange.

The

prop, with a tiny brass boss, was painted XF-9 hull red, then over-coated with

X-24 clear yellow, just to make it slightly different to the struts. I used some

rod to attach the prop to the engine, nothing was supplied with the kit. Photos

show the prop to be well forward of the cowling, a bit of trial fitting was

needed to get it looking right.

The

prop, with a tiny brass boss, was painted XF-9 hull red, then over-coated with

X-24 clear yellow, just to make it slightly different to the struts. I used some

rod to attach the prop to the engine, nothing was supplied with the kit. Photos

show the prop to be well forward of the cowling, a bit of trial fitting was

needed to get it looking right.

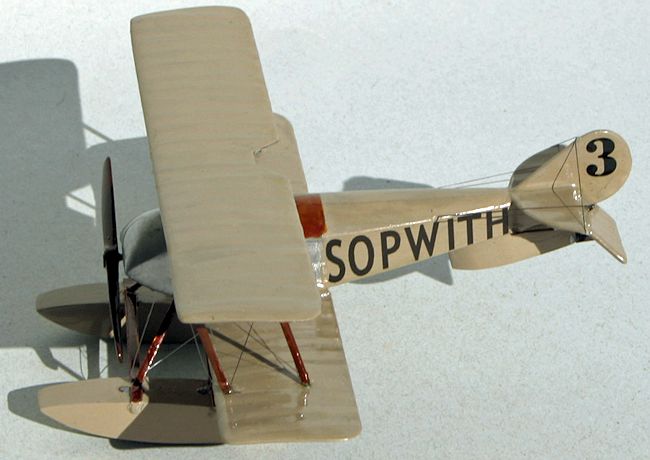

The HS had simple markings, A Sopwith logo on the fuselage sides, and the race

number, 3, on the tail. Using the draw program that came with Open Office, I

picked similar fonts and drew up the markings. After the usual trial and error,

I got the size about right, and laser printed the markings onto Microscale clear

trim film. As the markings were black text, not pictures, there was no problems

with pixelation.

I gave the model an overall coat of floor polish to help the decals. It looked

much better slightly gloss, so I gave it another coat over the decals.

I intended the model to represent the Sopwith HS on the 20th April 1914,

the day of the race. As it had only been assembled a few days before, and flown

once, I did not do any weathering, other than some oil staining under the cowl.

A number of brass control horns were supplied, and added as required.

A long and tedious job, about 30 rigging wires at about 15 minutes each,

and another couple of hours for the control wires. I can only do it in short

shifts, looking at and handling invisible threads, through an Optivisor makes me

cross-eyed.

The rigging adds a lot of strength and rigidity to a biplane model, and is well

worth the effort.

| CONCLUSIONS |

A modest conversion to produce an interesting aircraft, the first British

Schneider Trophy winner.

| REFERENCES |

Fortunately,

a number of high quality photographs of the HS were taken at Monaco, flying, on

the water and the beach. These photos formed the best reference for the model.

Fortunately,

a number of high quality photographs of the HS were taken at Monaco, flying, on

the water and the beach. These photos formed the best reference for the model.

C. G. Grey, Sea-Flyers, Faber and Faber, London, 1942

Owen Thetford, British Naval Aircraft since 1912, Putnam, London, 1958.

Malcolm Hall, Sopwith Aviation Company, History Press, Stroud, 2011

Ralph Pegram, Schneider Trophy Seaplanes and Flying boats, Fonthill, England,

2012

http://en.wikipedia.org/wiki/Sopwith_Tabloid

http://en.wikipedia.org/wiki/Gnome_Monosoupape

December 2014

If you would like your product reviewed fairly and fairly quickly, please contact the editor or see other details in the Note to Contributors.