1/72 Sopwith Type 806 Gunbus

| KIT #: | 01048 |

| PRICE: | £5.00 |

| DECALS: | One option |

| REVIEWER: | Stephen Foster |

| NOTES: |

Conversion using two kits |

This aeroplane, which

looked almost like a fossil bird, was a result of the request for a

two-seat anti-submarine patrol aircraft from the Greek Admiralty, and

was originally to have been a floatplane. It was one of the first of T.

Sopwith's aircraft to be designed specifically for military use: an

order for three with dual controls was placed by the Greek government in

1913, with a second order for six being placed in February 1914. These

were delivered as land planes with a four-wheel undercarriage between

July and October 1914, but most were commandeered by the British

Admiralty for use by the Royal Navy Air Service (RNAS). These were

numbered 801 - 806 and were named the Admiralty Type 806. In fact the

British Admiralty had ordered two machines in October 1913 and these

were delivered to the Isle of Grain in March 1914.

The term

"gunbus" is frequently associated with the Vickers FB5 and FB9 fighting

biplanes, but it was a generic term used at the time to describe any

armed scout or reconnaissance aircraft. The pusher design was adopted

because there was a lack of a reliable interrupter gear which would stop

the pilot from shooting off his own propeller. Instead the

observer/gunner had a wide field of fire and in the case of the Sopwith

Gunbus a 0.303 inch Lewis machine gun was sometimes mounted on a

telescopic pillar.

The term

"gunbus" is frequently associated with the Vickers FB5 and FB9 fighting

biplanes, but it was a generic term used at the time to describe any

armed scout or reconnaissance aircraft. The pusher design was adopted

because there was a lack of a reliable interrupter gear which would stop

the pilot from shooting off his own propeller. Instead the

observer/gunner had a wide field of fire and in the case of the Sopwith

Gunbus a 0.303 inch Lewis machine gun was sometimes mounted on a

telescopic pillar.

| CONSTRUCTION |

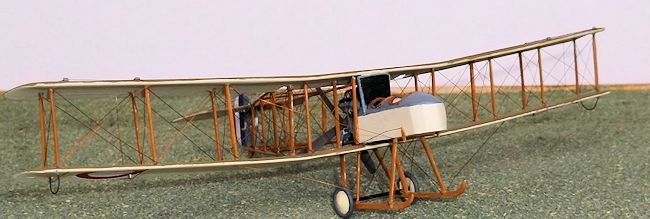

Like many other

little-known early aircraft types there is no model of this aircraft

produced in 1/72 scale, although card models in 1/48 and 1/50 scales are

available. The only reference to a conversion that I know of was by G.

Scarborough published in Airfix Magazine Annual No 5 in 1975 and I used

this as the basis for my model. G. Scarborough did not build a full

aircraft as his was part of a small diorama with the aeroplane partly

dismantled and being towed on a trailer, as illustrated in a series of

photographs of

Robey

built machines being taken from the factory in Lincoln to a nearby

testing field. In this diorama the wings and horizontal tail unit were

carried in the towing lorry. I have chosen to represent the entire

aircraft without any vehicles. There are two (possibly more) kits that

could be used as starting points: the Airfix Avro 504 (as in my model),

or the Airfix DH 4, both of which could provide wings, wheels, struts,

etc, but in either case you will need two kits unless you are prepared

to make part of the wings from card. I used G. Scarborough's method of

increasing the chord of the Avro 504 wings and kept the fuselages for

later use to correct the errors in that kit when I make different

variants of that famous type. The engines and propellors also proved

useful for the conversions of Vickers Gunbuses from D H 4's: it is

surprising how much of a kit can be used in different conversions.

Robey

built machines being taken from the factory in Lincoln to a nearby

testing field. In this diorama the wings and horizontal tail unit were

carried in the towing lorry. I have chosen to represent the entire

aircraft without any vehicles. There are two (possibly more) kits that

could be used as starting points: the Airfix Avro 504 (as in my model),

or the Airfix DH 4, both of which could provide wings, wheels, struts,

etc, but in either case you will need two kits unless you are prepared

to make part of the wings from card. I used G. Scarborough's method of

increasing the chord of the Avro 504 wings and kept the fuselages for

later use to correct the errors in that kit when I make different

variants of that famous type. The engines and propellors also proved

useful for the conversions of Vickers Gunbuses from D H 4's: it is

surprising how much of a kit can be used in different conversions.

Start by

making the fuselage nacelle. This was built from 20 thou card sides and

floor with three bulkheads, one at the point where the top decking

starts to curve at the nose end, one between the cockpits and one at the

rear. Construct a three sided box with the sides, floor and bulkheads

and add any cockpit detail including seats, and a control column, rudder

bar, etc in the front cockpit. The top decking was from 20 thou card

bent over the curved tops of the bulkheads and glued into place with

liquid cement. Cut a slot 20 thou wide in the top decking, 2mm behind

the rear cockpit to take the radiator which was made from card 11mm x

12mm with the surfaces scored to represent the radiator grill. The nose

of the nacelle was built up with scrap plastic and then covered with

filler and sanded to shape. The coamings around the cockpits were made

from thin rod or stretched sprue. The engine bearers were 15mm lengths

of rod inserted into holes drilled into the rear of the nacelle. The

rear support for the engine was cut from 20 thou card and cemented to

the rear ends of the engine bearer rods. Thin rod or sprue made the

additional

arms of the bearers, and card was used for the brackets at the front

end. The nacelle and engine bearers were painted before the engine was

cemented into place. Drill two holes under the nacelle to take the

undercarriage legs.

additional

arms of the bearers, and card was used for the brackets at the front

end. The nacelle and engine bearers were painted before the engine was

cemented into place. Drill two holes under the nacelle to take the

undercarriage legs.

The

engine was difficult to make as I could not find any good quality photos

or drawings: the drawings provided in the AM Annual were poor and not

very accurate but were among the better ones that I could find, so they

provided the basis for my efforts. Make the cylinder blocks from two

pieces of 60 thou laminated card with the ends rounded off. The engine

block/sump was also made from two pieces of 60 thou card, with a 20 thou

piece sandwiched between them. When this was dry I sanded to shape the

bottom and rear end, making sure that it fitted snugly into the space

between the engine bearers. The top of the engine block should slope

inwards to take the cylinder blocks. Drill a hole in the rear of the

engine block for the propellor. Assemble the cylinders to the engine

block and then add the exhaust pipes from short pieces of rod bent to a

curve. I put some very thin rod on the sides of the block to represent

pipes, and other tiny details as my imagination allowed. The assembly

was painted light grey with a little silver mixed in to give a metallic

finish. When the engine is finished cement the radiator to the nacelle

and the engine to the bearers, and then add the water pipes from the

cylinders to the radiator. I painted the water pipes copper with some

brown mixed in to take off the sheen. The exhaust pipes were rust. The

propellor blades were wide and had to be made from card and glued to the

boss of an old Camel(?) propellor which I found in the bottom of my

spares box which had had the original blades removed. (Why I had kept

this item I cannot remember: such are my hoarding tendencies). The

propellor was painted dark wood with a grey boss.

piece

4.9 cm long. Cut a similar length from the starboard(right) side of the

lower wing. These will form the centre sections of the new wings.

Finally cut two lengths 1.1 cm long from what is left of the inner

sections of the lower wing.

piece

4.9 cm long. Cut a similar length from the starboard(right) side of the

lower wing. These will form the centre sections of the new wings.

Finally cut two lengths 1.1 cm long from what is left of the inner

sections of the lower wing.

cut

and file shallow grooves on the top of the trailing edges of the wings

where the booms will be joined later. Strictly this is not accurate as

the booms were inserted into the rear of the wings but this is not

really practical on this model as the wings are so thin that the

resulting joint would be very weak.

cut

and file shallow grooves on the top of the trailing edges of the wings

where the booms will be joined later. Strictly this is not accurate as

the booms were inserted into the rear of the wings but this is not

really practical on this model as the wings are so thin that the

resulting joint would be very weak.

| COLORS & MARKINGS |

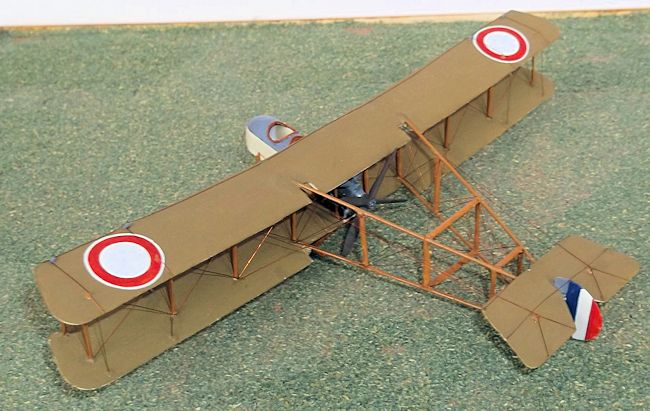

Markings

on these machines varied greatly as photographs show, so select the

machine you wish to model and use the photos to guide you. I based mine

on 3842 as it probably appeared in late 1915: photos of at least one,

possibly two machines show them with RNAS roundels under the wing tips

and rudder stripes and I assume that 3842 had similar markings. I

painted RNAS roundels on the upper wings: the photos clearly show the

white outer rings. To hand paint roundels scribe the outer circle with a

pair of dividers and then paint the inside of the circle white. When

this is dry scribe two concentric circles, again with the dividers, for

the red ring and then paint this. The paint will run into the grooves

made by the dividers and give you a nice clean edge, but you will need a

fine brush, a steady hand and thin paint. You may need to use two coats

of paint especially for the white. Alternatively you could use RNAS

roundels from the Pegasus transfer sheet early RNAS roundels and flags

(PGS 72 001) which I managed to find only after I had completed my

model. I also painted the white stripe on the fin for the serial but

whether this survived in service I cannot be sure. The serial came from

dry rub-down transfers and the rudder stripes were hand painted.

Markings

on these machines varied greatly as photographs show, so select the

machine you wish to model and use the photos to guide you. I based mine

on 3842 as it probably appeared in late 1915: photos of at least one,

possibly two machines show them with RNAS roundels under the wing tips

and rudder stripes and I assume that 3842 had similar markings. I

painted RNAS roundels on the upper wings: the photos clearly show the

white outer rings. To hand paint roundels scribe the outer circle with a

pair of dividers and then paint the inside of the circle white. When

this is dry scribe two concentric circles, again with the dividers, for

the red ring and then paint this. The paint will run into the grooves

made by the dividers and give you a nice clean edge, but you will need a

fine brush, a steady hand and thin paint. You may need to use two coats

of paint especially for the white. Alternatively you could use RNAS

roundels from the Pegasus transfer sheet early RNAS roundels and flags

(PGS 72 001) which I managed to find only after I had completed my

model. I also painted the white stripe on the fin for the serial but

whether this survived in service I cannot be sure. The serial came from

dry rub-down transfers and the rudder stripes were hand painted.

| FINAL CONSTRUCTION |

more

drops of glue on to the tops of the nacelle struts and run a little

along the top of the radiator and then gently lower the top wing so that

the leading edge of the top wing aligns with the edge of the radiator

and the nacelle struts enter the holes on the underside of the wing. The

pin on the bottom of the fin should drop into the apex of the V of the

lower boom: it can be glued with superglue. Although this structure

sounds weak it is stronger than you might think! Carefully cement two

struts into the outer holes of both sides of the wings: these came from

one of the 504's and should be the correct size without needing

adjustment. This sub-assembly can now be allowed to dry thoroughly and

you can go off and have a celebratory drink and relax as the most

difficult part is now over. Although this assembly will not stand rough

handling, when dry it can be manipulated sufficiently for the remaining

wing and the boom struts to be inserted with few problems. When it is

dry the remaining four struts from the second 504 kit can be inserted

into the wings and the rest either raided from the spares box or made

and shaped from card. The boom struts were made from card and inserted

using superglue to hold them in place. I inserted at least two sets of

boom struts before finishing the wings simply to make the structure a

little stronger. When the assembly is complete it is much stronger than

you think, but I do not recommend any test flights!

more

drops of glue on to the tops of the nacelle struts and run a little

along the top of the radiator and then gently lower the top wing so that

the leading edge of the top wing aligns with the edge of the radiator

and the nacelle struts enter the holes on the underside of the wing. The

pin on the bottom of the fin should drop into the apex of the V of the

lower boom: it can be glued with superglue. Although this structure

sounds weak it is stronger than you might think! Carefully cement two

struts into the outer holes of both sides of the wings: these came from

one of the 504's and should be the correct size without needing

adjustment. This sub-assembly can now be allowed to dry thoroughly and

you can go off and have a celebratory drink and relax as the most

difficult part is now over. Although this assembly will not stand rough

handling, when dry it can be manipulated sufficiently for the remaining

wing and the boom struts to be inserted with few problems. When it is

dry the remaining four struts from the second 504 kit can be inserted

into the wings and the rest either raided from the spares box or made

and shaped from card. The boom struts were made from card and inserted

using superglue to hold them in place. I inserted at least two sets of

boom struts before finishing the wings simply to make the structure a

little stronger. When the assembly is complete it is much stronger than

you think, but I do not recommend any test flights!

Now for

the fun part; rigging. There are about 140 individual wires to be put on

to this model (more than any other that I have made, and compared with

just over 50 on the DH 4), so expect it to take some time to complete.

Start by rigging the front to rear wires between the wing struts,

working from the centre outwards. Then rig the rear of the wings

followed by the front. The sides of the booms are next and when the rear

bays of the booms have been rigged the horizontal tail surfaces can be

glued into place. Rig the horizontal wires between the booms but before

you complete the forward bays put on the propellor. The undercarriage is

next and then the control wires on the wings and tail, the control wires

from the horns on the nacelle to the struts, and the tail bracing.

Finally add the elevator and rudder wires, the anti drag wires, and the

balance wire along the leading edge of the top wing. The tail skid and

wing skids (the latter made from 5 amp fuse wire) complete the model.

Now for

the fun part; rigging. There are about 140 individual wires to be put on

to this model (more than any other that I have made, and compared with

just over 50 on the DH 4), so expect it to take some time to complete.

Start by rigging the front to rear wires between the wing struts,

working from the centre outwards. Then rig the rear of the wings

followed by the front. The sides of the booms are next and when the rear

bays of the booms have been rigged the horizontal tail surfaces can be

glued into place. Rig the horizontal wires between the booms but before

you complete the forward bays put on the propellor. The undercarriage is

next and then the control wires on the wings and tail, the control wires

from the horns on the nacelle to the struts, and the tail bracing.

Finally add the elevator and rudder wires, the anti drag wires, and the

balance wire along the leading edge of the top wing. The tail skid and

wing skids (the latter made from 5 amp fuse wire) complete the model.

| CONCLUSIONS |

July 2014

Copyright ModelingMadness.com. All rights reserved. No reproduction in any form without express permission from the editor. If you would like your product reviewed fairly and fairly quickly, please

contact

the editor or see other details in the

Note to

Contributors.