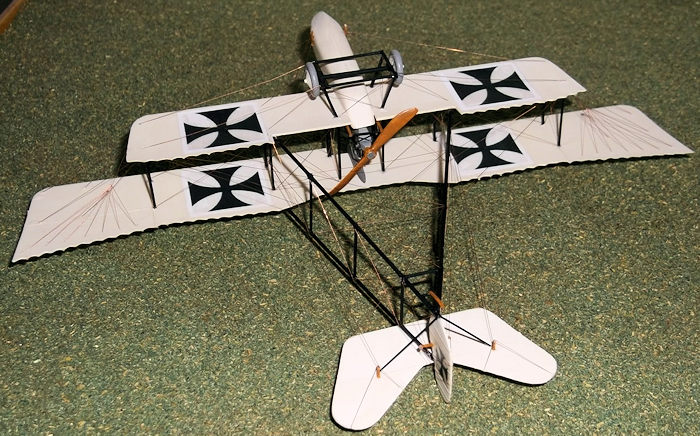

Gustav Otto was a Bavarian engineer who established a factory for

building aircraft in Munich in the years just before WW1. Unusually

for German designers he focussed on pusher machines, and according

to contemporary British sources these were copies of Farman designs.

In fact this was a little unfair as it would be more accurate to say

that he was inspired by the Farman designs as his machines were

considerably different in outline and construction. Whereas most

contemporary machines were built with wooden frames, Otto used

steel. This was a very marked innovation for the time as was his use

of elevators rather than wing warping which was common on most

contemporary French and British designs. The engine was mounted on a

platform above the rear of the nacelle and was an Argus of 100hp,

again a more powerful plant than most of its non-German

contemporaries. However the basic design went through many

variations over time, as did many other contemporary designs, as

Otto tried to refine and improve the basic idea. There were

variously machines with four fins and rudders, twin two-wheel

undercarriage units and various shapes to the nacelle. One

photograph shows an Otto without any nacelle at all as on the

Bristol Boxkite, with the pilot sitting fully exposed in the front

of the aircraft and the passenger equally exposed behind. It would

seem that by 1914 the design had settled to something like what I

have tried to represent in my model, but I cannot be certain of all

the details as there is little reliable information published in

English. Otto was also the owner of the Ago company which built the

C class of aircraft which was the subject of another scratch build

that I have posted on this site.

An interesting part of the story of this design involved Flying

Instructor Bruno Büchner who organised demonstration flights to

rally interest in aviation in South-West Africa, then a German

colony, now Botswana. He was given a biplane from the Pfalz-flugzeugwerke,

caller Doppelfalz, and told that after completing his displays he

was to fly overland to East Africa (also a German colony at the time

- now Tanzania), to give shows there. In May 1914, Büchner, his

wife, and a newspaper reporter arrived in Swakopmund with the

Doppelpfalz. He assembled and tested the plane at the coast and flew

to Windhoek. Conditions were far from ideal - the air was too thin

at that altitude and the aircraft was not really suitable for a

tropical environment. It was therefore decided that Büchner should

not fly to East Africa. He continued to performe at a few shows in

the South-West colony and undertook what was for those days long

distance flights to Usakos and Karubib, carrying post bags and even

a passenger. Eventually, the party arrived in Lüderitz by train. The

shows ceased in July when he had the aeroplane shipped in crates to

Dar-es-Salaam.

An interesting part of the story of this design involved Flying

Instructor Bruno Büchner who organised demonstration flights to

rally interest in aviation in South-West Africa, then a German

colony, now Botswana. He was given a biplane from the Pfalz-flugzeugwerke,

caller Doppelfalz, and told that after completing his displays he

was to fly overland to East Africa (also a German colony at the time

- now Tanzania), to give shows there. In May 1914, Büchner, his

wife, and a newspaper reporter arrived in Swakopmund with the

Doppelpfalz. He assembled and tested the plane at the coast and flew

to Windhoek. Conditions were far from ideal - the air was too thin

at that altitude and the aircraft was not really suitable for a

tropical environment. It was therefore decided that Büchner should

not fly to East Africa. He continued to performe at a few shows in

the South-West colony and undertook what was for those days long

distance flights to Usakos and Karubib, carrying post bags and even

a passenger. Eventually, the party arrived in Lüderitz by train. The

shows ceased in July when he had the aeroplane shipped in crates to

Dar-es-Salaam.

Büchner heard about the outbreak of the First World War in

Zanzibar Harbour. He returned to Dar-es-Salaam met the cruiser Königsberg.

On arrival he offered his aircraft to Oberstleutnant Paul von

Lettow-Vorbeck, the commander of the defence forces in German

East Africa. Von Lettow-Vorbeck ordered Büchner to undertake a

scouting mission in the direction of Zanzibar and Bagamoyo.

Flying along the coast he spotted two gunboats which immediately

opened fire and was wounded in the arm. On landing, the plane

struck deep sand and somersaulted. Büchner was thrown clear but

injured; he arrived at his base late in the evening and utterly

exhausted. While he was still in hospital, another officer,

Leutnant Henneberger, had the plane repaired and took off.

However, when he was attempting to la nd the aircraft clipped the

tops of palm trees and crashed killing the pilot even though the

plane was only lightly damaged.

nd the aircraft clipped the

tops of palm trees and crashed killing the pilot even though the

plane was only lightly damaged.

After his recovery Büchner was ordered to fit floats to his

plane and to support the Königsberg, which was then lying

disabled in the Rufiji Delta. The aircraft was rebuilt and

sheet-metal floats were attached. It was then found that there

was insufficient petrol available, and the project was

cancelled. The inventive Büchner fitted the aircraft's engine to

a small-gauge railway goods truck and, with this much admired Schienen-Zepp(Rail-Zepp[elin]),

undertook two goods transport trips to the inland town of

Morogoro. Following the occupation by the British, Büchner and

his wife were interned.

The military service career of these aircraft at home seems

to have been limited to reconnaissance on the Eastern front

by a very few machines. The Army did not like them because

they were considered to be badly constructed and the Navy

ordered several but these seem to have suffered from poor

construction too. However some machines do seem to have been

employed at least in the early months of the war before they

were withdrawn from service.

I started as usual by making a mould for the fuselage

nacelle using the standard push-mould technique. The

frame of the fuselage was thin rod and a simple

instrument panel added with a couple of dials was from

card. A compass from a thick piece of rod was cut and

mounted on the port side of the fuselage, together with

a control column, rudder bar and some seats. A fuel tank

was made from laminated card - this fits under the

engine platform in the rear of the nacelle. A gravity

tank which was under the top wing was made from a

cocktail stick. The engine was constructed from

laminated card for the sump and rod for the cylinders

with various bits of pipework from thin rod or stretched

sprue. The radiator was 40 thou card with the front and

rear scribed to give a pipe effect. The propellor was

carved from 60 thou card. The engine platform was made

from card and rod and glued to two strips of Evergreen

strip on the sides of the nacelle and top of the lower

wing. This can only be fitted after the lower wings are

in place.

carved from 60 thou card. The engine platform was made

from card and rod and glued to two strips of Evergreen

strip on the sides of the nacelle and top of the lower

wing. This can only be fitted after the lower wings are

in place.

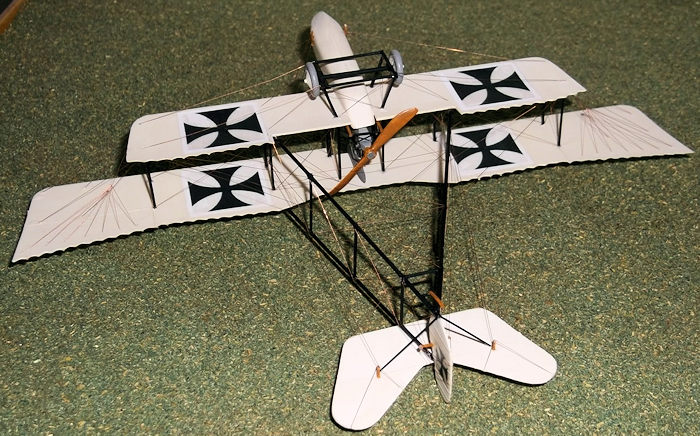

I cut the wings from bent 40 thou card and put on the

ribs from 1mm masking tape, varnished and slightly

rubbed down. Before putting on the ribs the wings were

sanded to an aerofoil section by thinning the trailing

edges and rounding off the leading edges. The shape of

the cut-out of the top wing seems to have varied a

little, as did the location of the gravity tank. The

trailing edge of the lower wing also varied from one

machine to another - I have modelled a simpler style but

there were also curved ones. Ailerons were on the top

wing only. These hung down when the aircraft was on the

ground and the control wires hung loose but as I use

copper wire for rigging this would have been impossible

for me to reproduce so I left my ailerons in the

horizontal position. I also cut the tail surfaces at

this stage.

I joined the lower wings to the fuselage one at a time.

This part is critical because the nacelle tapers so the

wing to fuselage joint must reflect this or the

alignments will be wrong and the model will look

horrible. The inner strut holes go right through the

wing because the undercarriage legs will fit into them

later. On the top wing the outer holes go right through

to mount king posts later. Mark on very carefully the

places where the booms will attach to the wings and

using the end of a round file grind out shallow grooves

that will later take the ends of the booms. The wooden

frames that support the engine platform to the fuselage

and lower wing were fixed next followed by the supports

for the platform. Glue the platform to the supports but

do not put on the engine until the platform and supports

are painted.

I painted the model at this stage. The scheme was

overall clear doped linen with black for the engine

platform. I also put on the markings on both wings and

the rudder. I printed my transfers on clear transfer

sheet having first painted the white square backgrounds

on the wings. I should have printed the crosses on to

white transfer sheet really, but then we can all be

wiser after the event.

The two struts which extend from the leading edge of the top wing to

the nacelle were from rod as was the undercarriage. Wheels from the

spares box, but they could easily have been made from card discs and

rod tyres. The tail skid was made from card, as were the control

horns on the flying surfaces. The

wing and tail king posts were rod.

wing and tail king posts were rod.

Paint all of the struts, booms, king posts and

undercarriage black, tyres light grey and propellor natural wood. Leave

the propellor and wheels off for the moment.Paint all of the struts,

booms, king posts and undercarriage black, tyres light grey and

propellor natural wood. Leave the propellor and wheels off for the

moment.Paint all of the struts, booms, king posts and undercarriage

black, tyres light grey and propellor natural wood. Leave the propellor

and wheels off for the moment. Paint all of the struts, booms, king

posts and undercarriage black, tyres light grey and propellor natural

wood. Leave the propellor and wheels off for the moment.

When the painting and markings were complete I added

the engine and radiator and a fuel pipe from the engine

to the fuel tank in the nacelle. I also added the side

braces between the sides of the radiator and the

platform and a pipe from the rear of the engine to the

rear of the radiator - this goes along the top of the

engine. There are other pipes on the sides of the egine

which can be added now or later. Fixing the wings can be

difficult but life becomes easier if you glue the four

inner struts into the holes in the lower wing and put

small blobs of glue into the inner holes on the

underside of the upper wing. Then gently lower the

upper wing and align the struts so that they are

vertical. Support the wings while this dries out

thoroughly. If this is done properly there should be no

problems with alignment and gap between the wings. When

the structure is dry the other struts can be added

carefully and the structure should be strong enough to

allow this procedure to proceed without problems. Many

people seem to think that building biplanes in this way

is difficult because the structure would be weak but

experiences proves otherwise. I cut my booms from

florists wire as this is stiff enough to hold the model

together and is completely straight, which I do not find

is the case with plastic rod. Fix the booms to the lower

wing first. I placed the model on a plan so I could

align them correctly in the horizontal plane. I then

measured from a side elevation of the plans the vertical

distance between the trailing edge of the wing and the

rear end of the boom. This gives the height of the

support that has to be put under the tail end of the

boom while the glue dries. I use epoxy as it gives me

time to make last moment adjustments and get everything

into the correct position before it hardens. The two

small bracing struts at the rear of the V were from

plastic rod held with superglue. I had drilled a small

hole in the base of the rudder and inserted a small pin

which I now placed into the V of the lower boom, again

with superglue to hold it. Hold the rudder in the

correct position while the

superglue dries. Then I can

add the upper booms to the top wing joints and brought

the rear ends to form a V on a small nick cut out in the

leading edge of the rudder - this latter joint was superglued. Note that in the horizontal plane the booms

converge towards the rear. The boom struts were be

measured individually with dividers and cut from rod and

put into place with superglue. This structure is strong

when it is all in place.

superglue dries. Then I can

add the upper booms to the top wing joints and brought

the rear ends to form a V on a small nick cut out in the

leading edge of the rudder - this latter joint was superglued. Note that in the horizontal plane the booms

converge towards the rear. The boom struts were be

measured individually with dividers and cut from rod and

put into place with superglue. This structure is strong

when it is all in place.

Paint all of the struts, booms, king posts and undercarriage

black, tyres light grey and propellor natural wood. Leave

the propellor and wheels off for the moment.

For the rigging I used 40 SWG copper wire rolled straight and held

in place with superglue. Measure the distances on the model with a

pair of dividers and cut each length individually. Work

systematically around the model and you are unlikely to miss any.

Place the most inaccessible ones first, and leave the most prominent

and therefore most likely damaged until last. Glue on the propellor

after you have rigged the sides of the booms but before you put in

the cross bracing, and the wheels until after you have rigged the

undercarriage frame but before you put on the under-wing bracing.

An interesting part of the story of this design involved Flying

Instructor Bruno Büchner who organised demonstration flights to

rally interest in aviation in South-West Africa, then a German

colony, now Botswana. He was given a biplane from the Pfalz-flugzeugwerke,

caller Doppelfalz, and told that after completing his displays he

was to fly overland to East Africa (also a German colony at the time

- now Tanzania), to give shows there. In May 1914, Büchner, his

wife, and a newspaper reporter arrived in Swakopmund with the

Doppelpfalz. He assembled and tested the plane at the coast and flew

to Windhoek. Conditions were far from ideal - the air was too thin

at that altitude and the aircraft was not really suitable for a

tropical environment. It was therefore decided that Büchner should

not fly to East Africa. He continued to performe at a few shows in

the South-West colony and undertook what was for those days long

distance flights to Usakos and Karubib, carrying post bags and even

a passenger. Eventually, the party arrived in Lüderitz by train. The

shows ceased in July when he had the aeroplane shipped in crates to

Dar-es-Salaam.

An interesting part of the story of this design involved Flying

Instructor Bruno Büchner who organised demonstration flights to

rally interest in aviation in South-West Africa, then a German

colony, now Botswana. He was given a biplane from the Pfalz-flugzeugwerke,

caller Doppelfalz, and told that after completing his displays he

was to fly overland to East Africa (also a German colony at the time

- now Tanzania), to give shows there. In May 1914, Büchner, his

wife, and a newspaper reporter arrived in Swakopmund with the

Doppelpfalz. He assembled and tested the plane at the coast and flew

to Windhoek. Conditions were far from ideal - the air was too thin

at that altitude and the aircraft was not really suitable for a

tropical environment. It was therefore decided that Büchner should

not fly to East Africa. He continued to performe at a few shows in

the South-West colony and undertook what was for those days long

distance flights to Usakos and Karubib, carrying post bags and even

a passenger. Eventually, the party arrived in Lüderitz by train. The

shows ceased in July when he had the aeroplane shipped in crates to

Dar-es-Salaam. nd the aircraft clipped the

tops of palm trees and crashed killing the pilot even though the

plane was only lightly damaged.

nd the aircraft clipped the

tops of palm trees and crashed killing the pilot even though the

plane was only lightly damaged. carved from 60 thou card. The engine platform was made

from card and rod and glued to two strips of Evergreen

strip on the sides of the nacelle and top of the lower

wing. This can only be fitted after the lower wings are

in place.

carved from 60 thou card. The engine platform was made

from card and rod and glued to two strips of Evergreen

strip on the sides of the nacelle and top of the lower

wing. This can only be fitted after the lower wings are

in place. wing and tail king posts were rod.

wing and tail king posts were rod. superglue dries. Then I can

add the upper booms to the top wing joints and brought

the rear ends to form a V on a small nick cut out in the

leading edge of the rudder - this latter joint was superglued. Note that in the horizontal plane the booms

converge towards the rear. The boom struts were be

measured individually with dividers and cut from rod and

put into place with superglue. This structure is strong

when it is all in place.

superglue dries. Then I can

add the upper booms to the top wing joints and brought

the rear ends to form a V on a small nick cut out in the

leading edge of the rudder - this latter joint was superglued. Note that in the horizontal plane the booms

converge towards the rear. The boom struts were be

measured individually with dividers and cut from rod and

put into place with superglue. This structure is strong

when it is all in place.