| KIT #: | 72010 |

| PRICE: | £10 second hand |

| DECALS: | Two options |

| REVIEWER: | Chris Peachment |

| NOTES: | Resin kit |

| HISTORY |

It

had a 135 hp. Thomas engine. Subsequent models included the V-1, with a 140hp

Sturtevant, V-2 with a 165 Hall Scott with a radiator under the upper wing, and

V-3 with a 200hp Sturtevant. One Model V-2 used to test the first 8 cylinder

Liberty engine. The aircraft had a monocoque fuselage made of wood and fabric.

It

had a 135 hp. Thomas engine. Subsequent models included the V-1, with a 140hp

Sturtevant, V-2 with a 165 Hall Scott with a radiator under the upper wing, and

V-3 with a 200hp Sturtevant. One Model V-2 used to test the first 8 cylinder

Liberty engine. The aircraft had a monocoque fuselage made of wood and fabric.

At

the end of the war, a Czechoslovakian delegation came to the US to buy aircraft

for their forces fighting with the

White Russians against the Communist Red Army. They ordered aircraft from LWF,

and were expecting more modern types, but LWF shipped 28 old Model

Vs, which were duly assembled and used by the Czechs in their battles

across Russia and Siberia in 1919-20. They all ending up in Vladivostok, and

were then shipped back to Czechoslovakia.

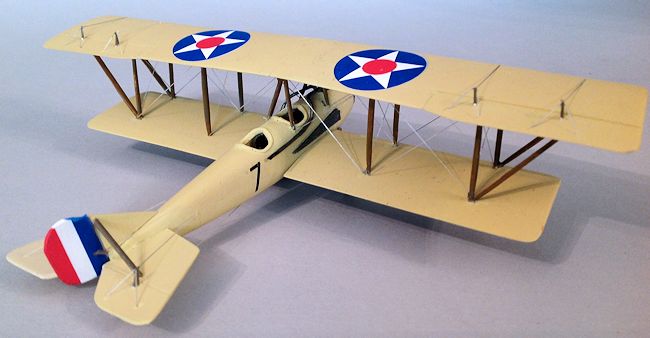

One aircraft is currently displayed in the National Technical Museum in Prague, carrying US markings on the wings and Czech tail stripes. Good photos are on websites listed below.

| THE KIT |

I

bought this from under the table of a dealer at a modelling show, mainly out of

curiosity because I knew little of the

aircraft, and one of the reasons I make models is to learn about

different types and their history. And it was cheap for a resin kit, which is

always a bonus in these straitened times. The mouldings are clean and don't

suffer from all the air holes I keep reading about. But the parts did need a lot

of separating from their sprues and resin flash, and then much cleaning up by

way of sanding seams. Once done, you will find the parts fit well, and the

surfaces have a pleasing rough texture to them, which replicates fabric well.

I

bought this from under the table of a dealer at a modelling show, mainly out of

curiosity because I knew little of the

aircraft, and one of the reasons I make models is to learn about

different types and their history. And it was cheap for a resin kit, which is

always a bonus in these straitened times. The mouldings are clean and don't

suffer from all the air holes I keep reading about. But the parts did need a lot

of separating from their sprues and resin flash, and then much cleaning up by

way of sanding seams. Once done, you will find the parts fit well, and the

surfaces have a pleasing rough texture to them, which replicates fabric well.

| CONSTRUCTION |

This

is only the second resin kit I have tried, and the previous one, a Vautour

French bomber, was straightforward compared to this. What I don't like about

them is having to use superglue, which is nasty stuff. It sets too quickly to

get alignment right, and this makes life tricky for a two bay biplane with

plenty of struts. And it glues your fingertips together, which is no aid to

modelling though may enrich your doctor. Plenty of warm water and prising apart

with a spoon handle is recommended, but you still end up with fingers like

sanding sticks. I sanded down the tailplanes with fingertips alone, thus making

a good saving on wet and dry paper.

The

interior is bare apart from floor, seats and sticks, and rudimentary instrument

panels. You might want to go to town here, as the rear cockpit is fairly

visible.

The

interior is bare apart from floor, seats and sticks, and rudimentary instrument

panels. You might want to go to town here, as the rear cockpit is fairly

visible.

You

might note in the photos that the Prague machine is heavily weathered. I

wondered whether to rub some dark brown powder all over the model, but then

remembered that what I always end up with is a badly painted model and not a

weathered one. So this one has just left the factory, which they all must have

done at some time in their lives.

The

cabanes proved a problem as they are moulded in one piece and the two vee-struts

are set too close together, to fit over the fuselage. Dry fitting resulted in

both snapping like dry wishbones. I soldiered on by re-gluing them at a wider

angle, but would have done better to replace them with styrene strut.

After

that, the top wing fitted surprisingly well. I found it best to glue the two

outer sets of struts in place, then gently spring the others into place. The

outer pair of slanted struts can be added last.

Rigging was done by my usual method. Elastic thread, coloured silver from a

gel pen, then anchored with small drops of superglue from a sharpened

toothpick. And that is a five second sentence describing two hours work.

Rigging was done by my usual method. Elastic thread, coloured silver from a

gel pen, then anchored with small drops of superglue from a sharpened

toothpick. And that is a five second sentence describing two hours work.

One

distinctive feature are the exhaust pipes which emerge upwards from the engine

cowl, then swoop down in an elegant curve through the cabanes. Again, the fit

was surprisingly good and need little coaxing. They are gunmetal, with some dark

rust here and there.

Another distinctive feature are those two beams on either side, flanking the

engine. I cannot make out what they are. They seem to be in the wrong place to

be engine bearers, and would hardly be uncovered if they were. Perhaps they are

some bizarre frame strengthening which was found necessary after test flight.

Anyway, they are gunmetal too, as is the front radiator.

The

fin marking should be applied now, and then the tailplanes. These are fragile

and I lost count of the times I knocked them off while handling. It is best to

get those support struts on as soon as possible to lend a little strength. But

it is a problem endemic to resin kits held with superglue. They will explode

like grenades at the slightest knock. And offer up their innards to the carpet

monster and the cat.

I

don't have carpets, preferring varnished boards, but they still manage to feast

on my lost struts which never reappear.

| CONCLUSIONS |

Perhaps I will come to love resin, but, as St Augustine begged in his

Confessions, 'make me good, Lord, but just not yet'. It is much cruder than

polystyrene and its flaws are evident wherever I look.

True, like all my failings, it is nothing but my own fault for not having

prepared each piece properly by scraping and sanding. But as the autumn of my

years is now well set in, and winter approaches, so time becomes more precious.

So many aircraft, so few models of them.

| REFERENCES |

http://wp.scn.ru/en/ww1/o/1699/104/0

October 2014

If you would like your product reviewed fairly and fairly quickly, please contact the editor or see other details in the Note to Contributors.