|

KIT # |

A 040 |

|

PRICE: |

$39.00 MSRP |

|

DECALS: |

Two aircraft |

|

REVIEWER: |

|

|

NOTES: |

Multimedia kit with some resin bits |

|

BACKGROUND |

Please visit the Preview for more information on the aircraft and a look at what comes in the box.

|

CONSTRUCTION |

Having not built a D.520 since I put together the 1/72 Frog

kit back in 1977, I thought that this one might not be a bad one to try.

I've been generally pleased with the way that MPM/Azur/Condor/Special

Hobby, etc have been improving over the last couple of years and this kit

looked like they are getting oh so close to being right up there with the

big boys. To me, one way of doing this is to slowly wean themselves from

having to rely on resin, etched metal and vacuformed canopies. This kit has

only a smattering of resin and none of the others. Now if they'd only stop

doing the individual prop blades........ The kit still has

some of the traits of a short run operation with ejector pin towers in some

of the larger parts such as the fuselage and by not having alignment pins.

However, I don't find those as any kind of impediment at all for often

alignment pins are more like mis-alignment pins and not having them also

keeps down the possibility of sink areas opposite them.

The wings have inserts for the landing gear attachment and

for the flaps that need to be glued in first. I also noted that the lower

wing had a bit of a downward warp in it which was taken out by some

judicial bending under hot water. The interior has some resin in it,

specifically the control stick, flap handle, rudder pedals, seat side

supports, trim wheel, and the bits for the gun sight. Nothing major

compared to earlier Azur kits. Of course, I had to use filler on a number

of these subassemblies, but for me, this is very much the norm, regardless

of whose kit I'm building. One thing did impress me and that was that

everything seems to fit quite well with minimal fuss. I also

glued in the radiator elements and cut out the radiator coolant door. The

replacement bit was glued in place in the down position, which was how it

was in every ground photo I saw of the D.520.

Interior assembly was completed by gluing the side panels and the back

piece. This rear piece did not fit perfectly well so before the glue dried

on these parts, I installed the interior into a fuselage half to make sure

that all fit. It seemed to fit well once tacked in place. I also glued the

back of the one side panels to the fuselage side, and left the other panel

off until I joined the fuselage halves.

With this done,

the fuselage halves were glued together. Fit was fair. I'd do a touch of

trimming on the interior aft bulkhead as it seemed to keep the halves from

easily fitting. As mentioned earlier, the resin intake was a touch too

wide. I had to use clamps to keep things together and used a combination of

super glue and regular Ambroid ProWeld. As you might expect from one of my

kits, putty was used.

With that drying, the horizontal stabilizers were glued on and fit here was

again, fairly good, though I did need filler. Returning to the wings, I

tried to install the flaps. They did not fit at all well in the up

position. I fear that this is a case of

After the first round of major sanding/filling, I glued on the front wing

insert, which fit quite well, and the lower radiator bath. Naturally, with

the step at the back of the wing, there's a gap that needs filled on both

sides of the rear of the radiator section. Thinking I was ready to apply

paint, I noticed I'd forgotten the side intakes. These have small

semi-circular inserts that you are to shape to fit the contours of the

nose. I noticed that these are handed in that they fit into one of the

intakes better than the other, so make sure you test fit these. Even after

a bit of carving, I had to use the 'let the glue melt the plastic a bit'

method for final fitting. Naturally, filler was used. The gunsight was also

glued into the interior and painted at this time. Next step was the

installation of the canopy bits. Fit here is very good indeed. I did use a

touch of filler on the back section and on the very front of the windscreen

where it had torn free from its sprue during shipping. I also took this

opportunity to drill out the wing gun recesses. CAMOUFLAGE

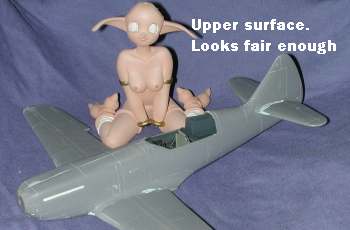

The upper surface was then painted using Aeromaster enamels and the paints called for in the

instructions. I started with Dark Blue (which isn't that dark), followed by

Dark Brown and then Khaki (which is really green). Needed a bit of back and

forth spraying to get things looking nice. This allowed me to check for seam glitches as well. I must

confess that I'd thought about doing the pre-shading that is so popular

nowadays, but decided against it. ATTACHING MORE BITS

Once the main colors were on, I brought the kit back to the bench to add

some additional bits before heading back to the paint shop. This consisted

with attaching the landing gear (which had been painted RLM 02 as a green

grey was called for) as well as gluing in place the upper and lower

antennas. On French fighters, they used a higher frequency radio which

eliminated the need for the usual long wire. What was needed to get

the proper RF coupling, was a lower a

On the main gear, there are two small resin bits for the retraction

mechanism. The lower one needs to be glued in place prior to gluing

in the main gear. The larger, upper one should be left off until the gear

is in place or you'll have a great deal of trouble getting the gear to fit.

I should also mention that during all this handling, I broke off the tip of

the pitot tube, and knocked the upper antenna off at least three times. I

left it off until the final bits. My suggestion for Azur is to provide a

mounting stub for this antenna as butt joins don't always hold well.

I mentioned that I wasn't going to pre-shade this kit, but I did decide to

post-shade it using pastels. The plane just looked too clean, and using a

dark grey, I went over all the panel lines and then used a clean rag to

wipe the majority of the pastels from the surface. The end was a

semi-grungy looking aircraft. I d DECALS

With the model properly grunged, I then lightly sprayed several coats of

Future clear gloss acrylic over it to seal in the pastels. It also provides

a smooth base for the decals. Not having much (as in none) in the way of

aftermarket decals, I had

Fortunately, the decals are

really excellent, though quite thin and with most of them being somewhat

large, care is needed when applying them. I had problems with tearing and

with the ends folding under, where they were a real bi**ch to straighten

out. I gave them all a touch of Solvaset to make sure they conformed. It

also seems to me that they were a tad oversize. At least the rudder stripes

are. You do have the option of painting on these stripes, so those who are

concerned about this can do so. Because of the oversize rudder stripes, I

had to cut the second one along the trailing edge of the rudder so that

there would be no overlap. Care and a sharp scalpel are needed. Any tears

can be mended using the other set of stripes. I started this kit as I do 99% of everything I do by first

looking over the instructions very carefully and then starting to build

subassemblies. The reason for this is that I can putty or paint a lot of

pieces at the same time and it allows me to maximize what is becoming less

and less time that I have to build a kit. Just to rattle off some of the

bits glued together at this time is much of the interior, the wheel halves,

the flaps (which are two part, for some reason), the wings, and the tail

planes. I should mention that I had to clamp the upper and lower wing

halves to ensure a good join, but no sanding or other adjustment to the

wheel wells was needed, which pleased me to no end.

I started this kit as I do 99% of everything I do by first

looking over the instructions very carefully and then starting to build

subassemblies. The reason for this is that I can putty or paint a lot of

pieces at the same time and it allows me to maximize what is becoming less

and less time that I have to build a kit. Just to rattle off some of the

bits glued together at this time is much of the interior, the wheel halves,

the flaps (which are two part, for some reason), the wings, and the tail

planes. I should mention that I had to clamp the upper and lower wing

halves to ensure a good join, but no sanding or other adjustment to the

wheel wells was needed, which pleased me to no end.

Interior bits were painted

French Interior Dark Blue using some of my remaining Aeromaster paints. The

seat cushion was painted in leather with the backing in a grey green

(actually Testors RLM 02). Handles and radio boxes in flat black, map pouch

in leather and the little buttons on the top of the handles and some lights

on the dash in red. I painted the instrument panel in flat black even

though the instructions list it as French Interior Dark Blue. The interior

bits were given a black wash and then dry-brushed with RLM 02.

Interior bits were painted

French Interior Dark Blue using some of my remaining Aeromaster paints. The

seat cushion was painted in leather with the backing in a grey green

(actually Testors RLM 02). Handles and radio boxes in flat black, map pouch

in leather and the little buttons on the top of the handles and some lights

on the dash in red. I painted the instrument panel in flat black even

though the instructions list it as French Interior Dark Blue. The interior

bits were given a black wash and then dry-brushed with RLM 02.  At this time, I removed the

resin exhaust from their backings and test fit them into the openings. They

are designed to fit from the outside, and I was worried that they may be a

bit too small and fall into the fuselage. My planning showed that this

would probably happen, so I cut some strips of styrene and backed up the

exhaust cut-outs. I also installed the small nose intake and made sure that

it fit properly. Hindsight shows that I needed to trim the sides down a

touch as there was a gap that needed filled.

At this time, I removed the

resin exhaust from their backings and test fit them into the openings. They

are designed to fit from the outside, and I was worried that they may be a

bit too small and fall into the fuselage. My planning showed that this

would probably happen, so I cut some strips of styrene and backed up the

exhaust cut-outs. I also installed the small nose intake and made sure that

it fit properly. Hindsight shows that I needed to trim the sides down a

touch as there was a gap that needed filled. Next was probably the worst

of the fit situations; installation of the wing. There were two areas of

concern. One is that either the fuselage was too wide at the wing root, or

the wings a bit too narrow. A bit of sanding on both the roots and the

inner wing area, got a fair fit, but it wasn't pretty. The rear section of

the wing also ended up with a rather noticeable step in it that I couldn't

get out. There was also a gap that I filled with sheet stock. Now I'm not

really sure just where the problem lies, but I'm leaning toward the flap

insert that fits in the back of the wing. I was unable to get the upper

wing to fit flush with it and that may well have contributed to problems.

Next was probably the worst

of the fit situations; installation of the wing. There were two areas of

concern. One is that either the fuselage was too wide at the wing root, or

the wings a bit too narrow. A bit of sanding on both the roots and the

inner wing area, got a fair fit, but it wasn't pretty. The rear section of

the wing also ended up with a rather noticeable step in it that I couldn't

get out. There was also a gap that I filled with sheet stock. Now I'm not

really sure just where the problem lies, but I'm leaning toward the flap

insert that fits in the back of the wing. I was unable to get the upper

wing to fit flush with it and that may well have contributed to problems.  where the kit is designed for flaps

down (which is not prototypical according to most of the pictures I saw),

and the flaps ended up being too tall for the openings. I'd go so far as to

suggest that if you decided to do your model with flaps up, that you leave

out the flap insert that goes on the aft wings. Not installing this part

will give you much greater leeway. I eventually had to take files, grinding

wheels and other implements of destruction to hack away at the flaps until

I got a semi-acceptable fit. It isn't pretty, I can tell you that!

where the kit is designed for flaps

down (which is not prototypical according to most of the pictures I saw),

and the flaps ended up being too tall for the openings. I'd go so far as to

suggest that if you decided to do your model with flaps up, that you leave

out the flap insert that goes on the aft wings. Not installing this part

will give you much greater leeway. I eventually had to take files, grinding

wheels and other implements of destruction to hack away at the flaps until

I got a semi-acceptable fit. It isn't pretty, I can tell you that!

Now for a bit of color. To my horror, I discovered that I'd run out of

Aeromaster French Underside Light Blue-Grey! My good friend Drew Nix came to

the rescue with some ModelMaster paint of the same shade and the underside

of the airframe was painted. As often happens when an area is painted, it

showed up some seam lines that needed some attention. A bit of superglue/accelerator

followed by a touch of Mr. Surfacer took care of those problems.

Now for a bit of color. To my horror, I discovered that I'd run out of

Aeromaster French Underside Light Blue-Grey! My good friend Drew Nix came to

the rescue with some ModelMaster paint of the same shade and the underside

of the airframe was painted. As often happens when an area is painted, it

showed up some seam lines that needed some attention. A bit of superglue/accelerator

followed by a touch of Mr. Surfacer took care of those problems.

ntenna that was often hinged so

it could be retracted while the plane was on the ground.

ntenna that was often hinged so

it could be retracted while the plane was on the ground.

no choice but to use those provided by the kit.

Naturally, since I didn't do the Vichy stripes, the only other choice was

the GC 1/3 plane as shown on the box art.

no choice but to use those provided by the kit.

Naturally, since I didn't do the Vichy stripes, the only other choice was

the GC 1/3 plane as shown on the box art.

|

FINAL CONSTRUCTION |

With the decals well on,

it was time to finish things up. First, the wheels were glued onto the

struts. I had to enlarge the holes to get these to fit properly. Then it

was time for the gear doors. I must have missed something as these were a

bit longer than they needed to be. The result was that I had to clip a bit

from the top sections to have them fit properly. BTW, I found it interesting

that these gear have no oleo scissors. I should mention that this is

apparently normal.

With the decals well on,

it was time to finish things up. First, the wheels were glued onto the

struts. I had to enlarge the holes to get these to fit properly. Then it

was time for the gear doors. I must have missed something as these were a

bit longer than they needed to be. The result was that I had to clip a bit

from the top sections to have them fit properly. BTW, I found it interesting

that these gear have no oleo scissors. I should mention that this is

apparently normal.

I found a color period photo of the plane on the box art and discovered

a few glitches, including that I should have painted all the wheels

aluminum instead of black, and that the landing gear doors are two piece.

It also appears that the upper radio mast is a light colo r such as white

and that the spinner is black and not dark blue. Prop blades do not seem to

have the yellow tips, either. I can fix the spinner and prop blades thing

at this point as it isn't glued on. It also seems as if the lower of three

small exhaust louvers behind the engine should be much larger in depth than

the upper two. Don't know why I discover these things when the model is

nearly done!

r such as white

and that the spinner is black and not dark blue. Prop blades do not seem to

have the yellow tips, either. I can fix the spinner and prop blades thing

at this point as it isn't glued on. It also seems as if the lower of three

small exhaust louvers behind the engine should be much larger in depth than

the upper two. Don't know why I discover these things when the model is

nearly done!

Well, I did repaint the blades, though I left the spinner in dark blue. Actually, I wanted to use the shorter spinner, but I couldn't get it to fit properly without hacking at it, while the longer one fit with no problems. I drilled out the broken off pitot tube and inserted a section of wire to replace that which had gone away. The radio mast was glued on for the umpteenth time and the formation lights painted in their appropriate colors. A bit of pastel was applied over the decals where needed and the plane given a coat of matte flat acrylic clear. The formation lights were painted with clear gloss and the masking taken off the canopy to complete the project.

|

CONCLUSIONS |

Well I

can't tell you how pleased I am with the results. Though not a trouble-free

build, it was certainly no more difficult than an old Monogram kit and

actually easier than many of them. Total build time from start to finish

was about two weeks, which for me is really speedy. It would be really

great if some aftermarket unit decals were available for it and only time

will tell if someone will be willing to make that commitment. Rarely does

one see aftermarket bits for a short run kit from other than the original

manufacturer, but it could happen.

Well I

can't tell you how pleased I am with the results. Though not a trouble-free

build, it was certainly no more difficult than an old Monogram kit and

actually easier than many of them. Total build time from start to finish

was about two weeks, which for me is really speedy. It would be really

great if some aftermarket unit decals were available for it and only time

will tell if someone will be willing to make that commitment. Rarely does

one see aftermarket bits for a short run kit from other than the original

manufacturer, but it could happen.

If your tastes are into 1/32 and you want something that will look good when you are done, then I can easily recommend this one.

August 2003

#1277 in a series

Copyright ModelingMadness.com. All rights reserved.

Kit courtesy of my credit card (for which Capital One is quite happy).

If you would like your product reviewed fairly and quickly, please contact me or see other details in the Note to Contributors.