| KIT #: | 09166 (Jt 106) |

| PRICE: | $Cheap as the box was badly accordioned. |

| DECALS: | Three options |

| REVIEWER: | Scott Van Aken |

| NOTES: |

| HISTORY |

The first major change since the more streamlined F

model was produced, was the 109G. The major difference in this aircraft was the

DB 605A engine of lar ger displacement and more horsepower. Of course, by this

time, the 109 needed the additional horsepower as the weight of the aircraft had

continued to grow. Though faster than the F in a straight line, it was not the

somewhat nimble dog-fighter that the F was. Not only that, but engine cooling

issues plagued the early G model and the Luftwaffe limited the amount of power

than the pilot could use until this issue was corrected. It was this issue that

took the life of Hans Marseilles in North Africa as his new G had the engine

seize from overheating and he died in the subsequent crash.

ger displacement and more horsepower. Of course, by this

time, the 109 needed the additional horsepower as the weight of the aircraft had

continued to grow. Though faster than the F in a straight line, it was not the

somewhat nimble dog-fighter that the F was. Not only that, but engine cooling

issues plagued the early G model and the Luftwaffe limited the amount of power

than the pilot could use until this issue was corrected. It was this issue that

took the life of Hans Marseilles in North Africa as his new G had the engine

seize from overheating and he died in the subsequent crash.

The G-2 was the standard fighter version of the new G as the G-1 was pressurized for higher altitude operations and few were built. The G-2 still had the F wheels so no wing wheel bulges. Also no bulges on the forward cowling that was part of the G-6 update. It did have a strengthened wing and larger framed canopy than the F. About 1600 G-2s were built.

| THE KIT |

Hasegawa's

G/K ,kits have been around a pretty long time. I would have to say at least 20

if not 25 years and are still the choice of

many modelers who want to build a

1/48 kit of this aircraft. What Hasegawa has done, is provide a basic Bf-109F

airframe and then add bits of sprue to make the version being kitted. This does

require some filling and hole opening to do non-F airframes, but the concept has

worked just fine for a long time.

many modelers who want to build a

1/48 kit of this aircraft. What Hasegawa has done, is provide a basic Bf-109F

airframe and then add bits of sprue to make the version being kitted. This does

require some filling and hole opening to do non-F airframes, but the concept has

worked just fine for a long time.

This is a somewhat special boxing in that it includes an Aeromaster decal sheet for its three markings options. The box art plane is Yellow 11 as flown by Herman Graf in 1942 when with 9. JG 52. Standard RLM 74/75/76 scheme with Eastern Front ID markings. The second is Walter Krupinski's plane, yellow 5 when he was with 6./JG 52 in late 1942. Same basic scheme as Graf's. The third is a desert scheme of 79/80/78 as flown by Heinz-Edgar Berres in Tunisia during 1943. For this one the usual Mediterranean white bits. All of this from 1995.

| CONSTRUCTION |

Building one of these is pretty straight forward as kits go. On this one, I

wanted to use a True Details resin cockpit. Sawing away at the bottom of the

cockpit section, I managed to break away one of the rudder pedal rests and one

of the small floor boxes. This caused me to set it aside and rethink my plans.

In the meanwhile, I opened the holes for the drop tank mount and carved away at

the wheel well openings. Hasegawa gives you the round F openings and for other

models, this additional material has to be removed. It is a simple process.

With that done, the fuselage halves were cemented together and the few seams

taken care of with super glue. The fuselage halves showed a bit of flash, not

surprising even in 1995 as this kit have been molded a ton of times.

Building one of these is pretty straight forward as kits go. On this one, I

wanted to use a True Details resin cockpit. Sawing away at the bottom of the

cockpit section, I managed to break away one of the rudder pedal rests and one

of the small floor boxes. This caused me to set it aside and rethink my plans.

In the meanwhile, I opened the holes for the drop tank mount and carved away at

the wheel well openings. Hasegawa gives you the round F openings and for other

models, this additional material has to be removed. It is a simple process.

With that done, the fuselage halves were cemented together and the few seams

taken care of with super glue. The fuselage halves showed a bit of flash, not

surprising even in 1995 as this kit have been molded a ton of times.

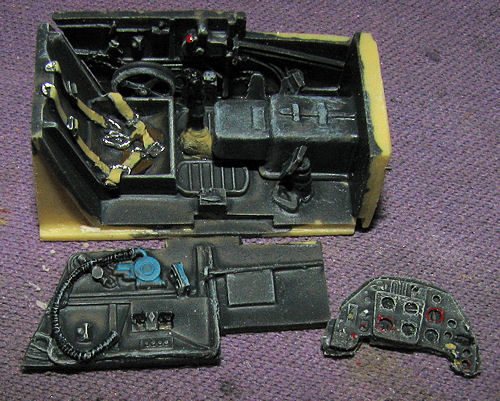

Back at the resin interior, I

got a bigger saw and got most of the pour stub off the bottom. I then painted

all of the interior pieces with Testors RLM 66 enamels using a brush. I then

detail painted the interior and instrument panel. True Details set 48490

includes a full color painting guide. When that was done, it was all lightly

dry-brushed using Citadel white. This may be a bit stark for some, but it

certainly does bring out detail. I then glued the forward bulkhead/gun cover and

one of the side panels. One uses the kit trim wheels on this. When I do side

panels like this that are glued to the tub, I generally angle them out a little

bit so that there will not be much in the way of gaps when the interior is

installed. The rudder pedals were cut from the resin and the control

column was

Back at the resin interior, I

got a bigger saw and got most of the pour stub off the bottom. I then painted

all of the interior pieces with Testors RLM 66 enamels using a brush. I then

detail painted the interior and instrument panel. True Details set 48490

includes a full color painting guide. When that was done, it was all lightly

dry-brushed using Citadel white. This may be a bit stark for some, but it

certainly does bring out detail. I then glued the forward bulkhead/gun cover and

one of the side panels. One uses the kit trim wheels on this. When I do side

panels like this that are glued to the tub, I generally angle them out a little

bit so that there will not be much in the way of gaps when the interior is

installed. The rudder pedals were cut from the resin and the control

column was  glued in place. Then

the other side panel was glued on and I test fit it into the fuselage. The

forward bulkhead sections need to be trimmed way back to get the resin cockpit

to fit. It is an easy task.

glued in place. Then

the other side panel was glued on and I test fit it into the fuselage. The

forward bulkhead sections need to be trimmed way back to get the resin cockpit

to fit. It is an easy task.

There are small holes in the very forward fuselage and the cowling covers

that need to be drilled out for the small cooling scoops. I recommend doing the

fuselage ones before cementing the halves together. Though I sorta followed the

instructions, I missed this until the haves were together and it was a bit more

difficult. The radiator inserts were then installed in the wings and the oil

cooler housing. Then the wings were glued together with no issues. Back at the

fuselage, I had to trim the resin instrument panel to fit. During this fitting

stage, the gun sight disappeared from the panel and a goodly search failed to

turn it up. Too bad as it was nicely detailed. I will undoubtedly use the kit

one in its place. The interior was then glued in and the fit was actually pretty

good. Next step was to drill out the barrels of the machine guns and then glue

that part to the fuselage.

Next major bit was to attach the wings. For this, I

glued the front and the rear portion first. The fit here was quite good. It has

been a while since I have built a kit that gave me few issues so it was a nice

break to have this one fit so well. I then glued on the

horizontal stabs before attaching

the engine cowlings. Here is where I had a pretty good sized fit issue. I got

the cowling to fit well all around, but to do so meant there was a sizeable gap

at the top. I could close the gap, but then the fit of the rest of the cowling

would be poor.

To see if this was just a one shot I checked an earlier 109F

build I did and found the same thing. As in that build, I simply filled the gap

with super glue and sanded it down smooth. It took a couple of applications.

To see if this was just a one shot I checked an earlier 109F

build I did and found the same thing. As in that build, I simply filled the gap

with super glue and sanded it down smooth. It took a couple of applications.

The next area of work was the flaps and the radiator

outlets. There are several poses for the radiator outlets, but the one I

generally choose is the upper flap level with the wing while the lower one is

deflected down. This will take a couple of glue applications. The first to get

it into position and the second to make

sure it stays there. I also glued

the flaps in the lowered position. These items have large sink areas on the top

and bottom and should be filled prior to installation. Again, two glue

applications are recommended as per the radiator exhaust flaps. I also glued on

the oil cooler housing and the rack for the drop tank. The supercharger intake

was glued together and attached. Note that these were from thin stamped metal

and there should be a prominent exterior seam so don't remove it.

was glued together and attached. Note that these were from thin stamped metal

and there should be a prominent exterior seam so don't remove it.

The prop was assembled and painted RLM 70. Next, the small aileron balances were glued on. At the cockpit, the kit gun sight was installed and I cemented the backlight clear bit into place. Next, the windscreen was masked and glued on followed by the canopy, which was simply tacked into place. There is a bit of a step at the very front of the windscreen. Whether this is a result of the resin interior or not, it required some filler. With the inside pretty well covered up, it was time to think about painting.

| COLORS & MARKINGS |

First of all, a scheme had to be found. There are not

a lot of decals for the G-2 or the G-4, but they can be found if you have enough

decal sheets on hand. Fortunately, I have several dozen 1/48 109 sheets in the

collection and after a bit of hunting, found a couple I liked. I finally settled

on a scheme in Aeromaster's Augsburg Eagles part XI, sheet 48-461, printed in

1999, so it was relatively new as old sheets go. This was the aircraft of Oberst

Gunther Rall when with 8./JG 52 in the Fall of 1942. As a typical Russian Front

plane, it had yellow bits under the cowling, wing tips and a yellow fuselage

band. The aircraft was in RLM 74/75/76 with a rather heavily over-painted

fuselage. An interesting sort of scheme that I was seeking. Despite Rall being

the third highest scoring fighter pilot of all time, there were no victory

markings on this aircraft.

First of all, a scheme had to be found. There are not

a lot of decals for the G-2 or the G-4, but they can be found if you have enough

decal sheets on hand. Fortunately, I have several dozen 1/48 109 sheets in the

collection and after a bit of hunting, found a couple I liked. I finally settled

on a scheme in Aeromaster's Augsburg Eagles part XI, sheet 48-461, printed in

1999, so it was relatively new as old sheets go. This was the aircraft of Oberst

Gunther Rall when with 8./JG 52 in the Fall of 1942. As a typical Russian Front

plane, it had yellow bits under the cowling, wing tips and a yellow fuselage

band. The aircraft was in RLM 74/75/76 with a rather heavily over-painted

fuselage. An interesting sort of scheme that I was seeking. Despite Rall being

the third highest scoring fighter pilot of all time, there were no victory

markings on this aircraft.

First step in painting was to paint the areas that

would be done in yellow with an underlying white. For this, I used Tamiya Gloss

White. The RLM 04 was from the Agama line. These areas were masked and the

underside was painted with Testors Model Master RLM 76. For the upper surface

RLM 74/75 I also used Model Master enamels. The 74 was sprayed on first followed

by the wing and tail camo in 75. This was free-handed and a bit ragged as the

instructions showed it like this. I then went back over the side areas

with RLM 76 after masking the wings and stabs to prevent issues with overspray.

This was followed by the mottling in RLM 75 and some additional detail work with

the RLM 76.

First step in painting was to paint the areas that

would be done in yellow with an underlying white. For this, I used Tamiya Gloss

White. The RLM 04 was from the Agama line. These areas were masked and the

underside was painted with Testors Model Master RLM 76. For the upper surface

RLM 74/75 I also used Model Master enamels. The 74 was sprayed on first followed

by the wing and tail camo in 75. This was free-handed and a bit ragged as the

instructions showed it like this. I then went back over the side areas

with RLM 76 after masking the wings and stabs to prevent issues with overspray.

This was followed by the mottling in RLM 75 and some additional detail work with

the RLM 76.

When that was done, the wheel wells were painted in RLM 02 and the masking taken off the flight surfaces. I then installed the main gear legs and the tail gear. This allowed the kit to stand on its gear while it was sprayed with Future in preparation for the decals.

These Aeromaster decals were printed in Mexico and while colorful and in register, I found that they not only took considerable time to come clear of the backing sheet, but seemed to be a bit oversize when compared to the placement diagram. A few of the markings were two piece and this includes some of the data markings. Otherwise, they worked well with Microsol setting solution and are properly opaque. As usual, it took me nearly a week to apply even this small number of markings as I would do a few, let them dry, apply setting solution and then let it dry overnight before doing others.

| FINAL BITS |

With all the decals in place, I then started attaching other pieces. This included the gear covers and the resin Ultracast wheels. You actually do not need the Ultracast wheels as the kit wheels are fine. These are a bit wider and offer a touch more detail, but are not a major improvement over the kit versions. The big benefit is not having to remove the mold seam that goes around the circumference of the tire.

I also glued

on the radio mast before giving the airframe a coat of near matte clear using

Future and Tamiya Flat Base mixed together. This effectively sealed the decals

in place. One of the many 109 detail bits I had in my stash was a set of

Quickboost resin exhaust. The major improvement of these over the kit exhaust is

that the seams are intact and the exhaust ends are slightly opened up. On the

kit exhaust, there are a pair of sprue attachment points on the outside of the

exhaust stacks and you will destroy the seam that is supposed to be there when

you remove them. These had the shields placed atop them and were press fit into

the openings. They are a tight fit.

I also glued

on the radio mast before giving the airframe a coat of near matte clear using

Future and Tamiya Flat Base mixed together. This effectively sealed the decals

in place. One of the many 109 detail bits I had in my stash was a set of

Quickboost resin exhaust. The major improvement of these over the kit exhaust is

that the seams are intact and the exhaust ends are slightly opened up. On the

kit exhaust, there are a pair of sprue attachment points on the outside of the

exhaust stacks and you will destroy the seam that is supposed to be there when

you remove them. These had the shields placed atop them and were press fit into

the openings. They are a tight fit.

The prop was then glued to the hub, the masking taken off the clear bits and the canopy posed open after the head armor was installed. The radio mast and pitot tube were then painted. I used EZ-Line to make a radio antenna as well as the cable that holds the canopy. Pastels were used for the exhaust and detail stuff like the position lights and areas that needed a bit of touch up were taken care of.

| CONCLUSIONS |

Yet another

109 to add to the shelves. I am an unabashed 109 fan and will keep building them

until I can no longer build models of any sort. The Hasegawa family of kits are

the right combination of detail and relative ease of building that keep people

coming back to them time and time again. I like that if you want to build them

right out of the box, you can do so and have a very nice model when done. You

can also load them up with aftermarket if that is your choice and have an even

nicer model.

Yet another

109 to add to the shelves. I am an unabashed 109 fan and will keep building them

until I can no longer build models of any sort. The Hasegawa family of kits are

the right combination of detail and relative ease of building that keep people

coming back to them time and time again. I like that if you want to build them

right out of the box, you can do so and have a very nice model when done. You

can also load them up with aftermarket if that is your choice and have an even

nicer model.

| REFERENCES |

Probably used Wikipedia for some of the background, but really, most of it came from just knowing quite a bit about the aircraft.

December 2012 If you would like your product reviewed fairly and fairly

quickly, please

contact

the editor

or see other details in the

Note to

Contributors.