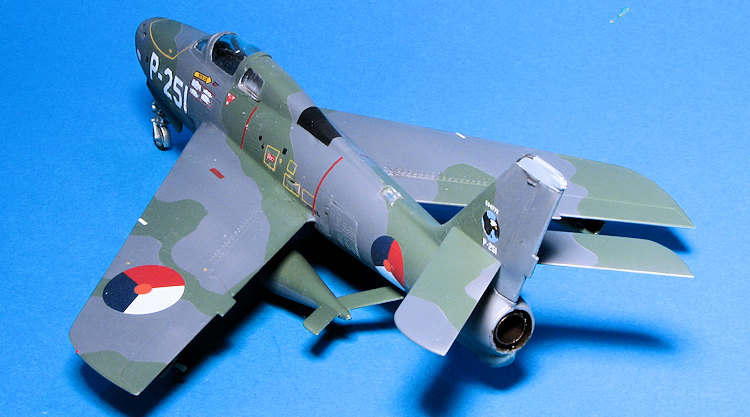

Airfix 1/72 F-84F Thunderstreak

| KIT #: | 3022 |

| PRICE: | $2.00 in a bag |

| DECALS: | None |

| REVIEWER: | Scott Van Aken |

| NOTES: | 1974 tooling. No instructions or decals |

| HISTORY |

In 1949, a swept wing version of the F-84 was created

with the hope of bringing performance to the level of the F-86. The last

production F-84E was fitted with a swept tail, a new wing with 38.5 degrees of

leading edge sweep and 3.5 degrees of anhedral, and a J35-A-25 engine producing

5,300 pound-force (23.58 kN) of thrust. The aircraft was designated XF-96A. It

flew on 3 June 1950 with Otto P. Haas at the controls. Although the airplane was

capable of 602 knots (693 mph, 1,115 km/h), the performance gain over the F-84E

was considered minor. Nonetheless, it was ordered into production in July 1950

as the F-84F Thunderstreak. The F-84 designation was retained because the

fighter was expected to be a low-cost improvement of the straight-wing

Thunderjet with over 55 percent commonality in tooling.

was considered minor. Nonetheless, it was ordered into production in July 1950

as the F-84F Thunderstreak. The F-84 designation was retained because the

fighter was expected to be a low-cost improvement of the straight-wing

Thunderjet with over 55 percent commonality in tooling.

In the meantime, the USAF, hoping for improved high-altitude performance from a more powerful engine, arranged for the British Armstrong Siddeley Sapphire turbojet engine to be built in the United States as the Wright J65. To accommodate the larger engine, YF-84Fs with a British-built Sapphire as well as production F-84Fs with the J65 had a vertically stretched fuselage, with the air intake attaining an oval cross-section. Production delays with the F-84F forced the USAF to order a number of straight-wing F-84Gs as an interim measure.

Production quickly ran into problems. Although tooling commonality with the Thunderjet was supposed to be 55 percent, in reality only fifteen percent of tools could be reused. To make matters worse, the F-84F utilized press-forged wing spars and ribs. At the time, only three presses in the United States could manufacture these, and priority was given to the Boeing B-47 Stratojet bomber over the F-84. The YJ65-W-1 engine was considered obsolete and the improved J65-W-3 did not become available until 1954. When the first production F-84F finally flew on 22 November 1952, it differed from the service test aircraft. It had a different canopy which opened up and back instead of sliding to the rear, as well as airbrakes on the sides of the fuselage instead of the bottom of the aircraft. The aircraft was considered not ready for operational deployment due to control and stability problems. The first 275 aircraft, equipped with conventional stabilizer-elevator tailplanes, suffered from accelerated stall pitch-up and poor turning ability at combat speeds. Beginning with Block 25, the problem was ameliorated by the introduction of a hydraulically powered one-piece stabilator. A number of aircraft were also retrofitted with spoilers for improved high-speed control. As a result, the F-84F was not declared operational until 12 May 1954.

Project Run In completed operational tests in November 1954 and found the

aircraft to be to USAF satisfaction and considerably better than the F-84G.

However, ongoing engine failures resulted in the entire fleet being grounded in

early 1955. Also, the J65 engine continued to suffer from flameouts when flying

through heavy rain or snow. As the result of the problems, the active duty phaseout began almost as soon as the F-84F entered service in 1954, and was

completed by 1958. Increased tensions in Germany associated with construction of

the Berlin Wall in 1961 resulted in reactivation of the F-84F fleet. In 1962,

the fleet was grounded due to the corrosion of control rods. A total of 1,800

man hours were expended to bring each aircraft to full operational capacity.

Stress corrosion eventually forced the retirement of ANG F-84Fs in 1971.

Project Run In completed operational tests in November 1954 and found the

aircraft to be to USAF satisfaction and considerably better than the F-84G.

However, ongoing engine failures resulted in the entire fleet being grounded in

early 1955. Also, the J65 engine continued to suffer from flameouts when flying

through heavy rain or snow. As the result of the problems, the active duty phaseout began almost as soon as the F-84F entered service in 1954, and was

completed by 1958. Increased tensions in Germany associated with construction of

the Berlin Wall in 1961 resulted in reactivation of the F-84F fleet. In 1962,

the fleet was grounded due to the corrosion of control rods. A total of 1,800

man hours were expended to bring each aircraft to full operational capacity.

Stress corrosion eventually forced the retirement of ANG F-84Fs in 1971.

In what is probably one of the very few air-to-air engagements involving the F-84F, two Turkish Air Force F-84F Thunderstreaks shot down two Iraqi Il-28 Beagle bombers that crossed the Turkish border by mistake during a bombing operation against Iraqi Kurdish insurgents. This engagement took place on 16 August 1962.

The F-84F was retired from active service in 1964, and replaced by the North American F-100 Super Sabre and relegated to duty in the Air National Guard. The last F-84F Thunderstreak retired from the ANG in 1971. Three Hellenic Air Force RF-84Fs that were retired in 1991 were the last operational F-84s.

| THE KIT |

This kit was purchased from the dead kit table at the LHS and while the bag

was still sealed, there were no instructions or decals. Not an issue for

many of us and I do have an MPC boxing of this which supplied the required

rovides space for nose weight, though there

is no indication that any is required. There is a bulkhead right after the

intake section and one behind the cockpit that fit into slots in the fuselage. A

reasonably long tail pipe is also provided with a blanking bit to fit in the

end, preventing 'see-through'.

rovides space for nose weight, though there

is no indication that any is required. There is a bulkhead right after the

intake section and one behind the cockpit that fit into slots in the fuselage. A

reasonably long tail pipe is also provided with a blanking bit to fit in the

end, preventing 'see-through'.

| CONSTRUCTION |

avity in the well was filled with weight. The intake

areas were painted with Alclad II aluminum.

avity in the well was filled with weight. The intake

areas were painted with Alclad II aluminum. | COLORS & MARKINGS |

There seems to be a real dearth of 1/72 markings for the F-84F, which is

somewhat surprising considering how many were built and how many served in

USAF and ANG markings. However, the type was exported and so there are other

options. For this build, I decided to go with Dutch Decals 72069 which

includes a number of F-84F options. I wonder if DD is still around as they

have not sent in any review samples for several years.

There seems to be a real dearth of 1/72 markings for the F-84F, which is

somewhat surprising considering how many were built and how many served in

USAF and ANG markings. However, the type was exported and so there are other

options. For this build, I decided to go with Dutch Decals 72069 which

includes a number of F-84F options. I wonder if DD is still around as they

have not sent in any review samples for several years.  At that point the already painted landing gear was glued in place. This was

followed by the pylons. I should mention that the pylons have issues with

ejector marks. On some there are detents and on the other there are stubs,

but all have at least two. This was also an issue with the inner gear doors

as well as these parts having sink areas. There was considerable flash in

the details of the main wheels as well, something difficult to clean up.

After installing all but the outer main gear doors, I did some touch up

painting and then gave the airframe a clear coat in preparation for the

decals.

At that point the already painted landing gear was glued in place. This was

followed by the pylons. I should mention that the pylons have issues with

ejector marks. On some there are detents and on the other there are stubs,

but all have at least two. This was also an issue with the inner gear doors

as well as these parts having sink areas. There was considerable flash in

the details of the main wheels as well, something difficult to clean up.

After installing all but the outer main gear doors, I did some touch up

painting and then gave the airframe a clear coat in preparation for the

decals. | CONCLUSIONS |

| REFERENCES |

May 2016