|

KIT: |

Anigrand 1/72 XF-108 Rapier |

|

KIT # |

AA-2018 |

|

PRICE: |

$64.50 MSRP |

|

DECALS: |

One option |

|

REVIEWER: |

Scott Van Aken |

|

NOTES: |

Resin kit with vac canopy |

|

HISTORY |

The F-108A Rapier was destined to be the last fighter project carried out by North American Aviation, builders of such immortals as the P-51 Mustang and the F-86 Sabre.

The F-108 project was originally known as the LRIX (Long-Range Interceptor, Experimental) and was initiated by the Air Force on October 6, 1955. On June 6, 1957, North American was issued a letter contract for two prototypes of a long-range, high-performance interceptor to be designated F-108A. The company designation for the aircraft was NA-257. It was to be capable of Mach 3 performance and was intended to serve as a long-range interceptor that could destroy attacking Soviet bombers over the poles before they could get near US territory. It was also to serve as the escort fighter for the XB-70 Valkyrie Mach-3 strategic bomber, also to be built by North American. The Air Force expected that the first F-108A would be ready for service by early 1963. An order for no less than 480 F-108s was anticipated.

The F-108A design that North American ultimately produced called for a large delta-winged aircraft powered by a pair of afterburning General Electric J93-GE-3AR turbojets fed by variable inlets mounted underneath the wing roots. The F-108 aircraft was designed for a maximum speed of 1980 mph at 75,550 feet and for a 1020-mile combat radius. The pilot and radar operator sat in tandem individual ejector capsules in the forward cockpit. The aircraft was to be equipped with an extremely sophisticated avionics system, directed by the Hughes AN/ASG-18 search and tracking radar which was to have a range of over 100 miles.

The F-108A was to be armed with three advanced Hughes GAR-9 Falcon missiles housed in an internal weapons bay. The GAR-9 missile was powered by a Lockheed storable liquid-propellant rocket motor which was capable of driving the missile to hypersonic speeds of up to Mach 6 and achieving ranges of up to 115 miles. The GAR-9 missile used semiactive radar homing for midcourse guidance, with passive infrared homing being used for the final run-in to the target.

A mockup was

inspected in January 1959, with the initial flight being planned for

March 1961. The popular name *Rapier* was assigned on May 15, 1959.

A mockup was

inspected in January 1959, with the initial flight being planned for

March 1961. The popular name *Rapier* was assigned on May 15, 1959.

However, by mid 1959, the Air Force was already beginning to experience some doubts about the high cost of the Rapier program. The primary strategic threat from the Soviet Union was now perceived to be its battery of intercontinental ballistic missiles instead of its force of long-range bombers. Against intercontinental ballistic missiles, the F-108A interceptor would be completely useless. In addition, the Air Force was increasingly of the opinion that unmanned intercontinental ballistic missiles could accomplish the mission of the B-70 Valkyrie/F-108 Rapier combination much more effectively and at far lower cost. Consequently, the F-108A project was cancelled in its entirety on September 23, 1959, before any prototypes could be built. The XB-70 project was also halted, and on December 3, 1959 was cut back to only two prototypes.

The work on the Rapier did not entirely go to waste. The work that Hughes did on the AN/ASG-18 radar was later transferred over to the Lockheed YF-12A interceptor project, and the GAR-9 Falcon (redesignated AIM-47A in 1962) missile originally developed for the F-108A was used to arm the YF-12A.

Two General Electric J93-GE-3AR turbojets, 20,900 lb.s.t. dry, 30,000 lb.s.t. with afterburner. Maximum speed: 1980 mph at 76,550 feet. Service ceiling 80,100 feet, combat ceiling 76,550 feet. Initial climb rate 18,000 feet per minute. Climb to 50,000 feet in 5.4 minutes. Combat radius 1020 miles with three missiles. 2488 miles ferry range. Dimensions: wingspan 57 feet 5 inches, length 89 feet 2 inches, height 22 feet 1 inches, wing area 1865 square feet. Weights: 50,907 pounds empty, 76,118 pounds combat, 102,533 pounds gross. Armed with three Hughes GAR-9 Falcon air-to-air missiles.

|

THE KIT |

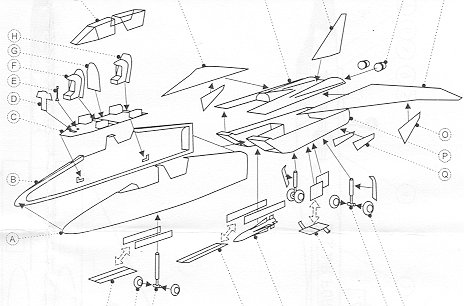

If you have read any of the other reviews of Anigrand kits, then this one will follow a similar theme. I should first mention that this is going to build into a big model. Comparing it with my RA-5C model, this one is larger. I've shown the exploded construction diagram to show the parts as it does a much better job than laying out the pieces. As with an F-15 or F-15 kit, it is a four part fuselage with the aft section in horizontal halves and the forward section split vertically. No mention of nose weight is given, and like a Tomcat, I doubt if any is needed.

Now on to some specifics. Anigrand's kits are no different from the vast majority of short run resin kits in the number of glitches it has. The truth is that a set of molds is only good for a small number of kits. If these makers tossed all the parts that had problems, they'd only be able to do a small number of kits. However, some companies are able to meet those higher standards so Anigrand should be able to as well. I should point out that every kit is different and if one kit has a poorly done part, the odds are that the next will not and will have something different. What follows are some images of the problem areas in my kit. None are impossible to fix, though some will be difficult.

I'll

begin with those bits I'm not showing. I had huge air bubble gaps in the

aft fins of the missile and the large underwing ventral strakes. I also

had a bulkhead behind one of the seats with a huge chunk broken off. The

piece is not in the bag so it was packaged broken. I can understand a bit

breaking in transit, but to be packaged broken is not acceptable. The

first are is the forward edge of the upper and lower fuselage halves

(image 1). These have a number of broken air bubble areas. In addition

the lower intakes, besides being a mass of air bubbles, are not the same

and uneven. This will require some sawing and replacement with card stock

to even things out and the usual superglue fix will be way too time

consuming.

I'll

begin with those bits I'm not showing. I had huge air bubble gaps in the

aft fins of the missile and the large underwing ventral strakes. I also

had a bulkhead behind one of the seats with a huge chunk broken off. The

piece is not in the bag so it was packaged broken. I can understand a bit

breaking in transit, but to be packaged broken is not acceptable. The

first are is the forward edge of the upper and lower fuselage halves

(image 1). These have a number of broken air bubble areas. In addition

the lower intakes, besides being a mass of air bubbles, are not the same

and uneven. This will require some sawing and replacement with card stock

to even things out and the usual superglue fix will be way too time

consuming.

The next shot (image 2) is of left side of the lower

fuselage half. As you can see, the casting here is not very good with all

sorts of rough areas. This is not precisely where the wing butts, but

beneath that area. You can also see some air bubbles on the back half

where the exhaust attach. These are on the inside and not repeated on the

other side. This is a good time to talk about the wing. The wing and tail

are very thin. They are also supposed

to be butt joined and

joined about where the upper and lower fuselage seam is located. I am

going to make some pins out of paper clips as I seriously doubt that a

straight butt join will hold up for very long. Anyway, on my kit, the

leading edge of one of the wings has a rather large gouge in it (image

3). You'll also note that there are some air bubbles just below the

surface of a thin skin of resin. This will require some very careful

sanding and undoubtedly, some filling will be needed as well. Fixing the

gouge can be done with repeated doses of gap filling superglue, followed

by accelerator and a final sanding (being careful not to get too carried

away!).

to be butt joined and

joined about where the upper and lower fuselage seam is located. I am

going to make some pins out of paper clips as I seriously doubt that a

straight butt join will hold up for very long. Anyway, on my kit, the

leading edge of one of the wings has a rather large gouge in it (image

3). You'll also note that there are some air bubbles just below the

surface of a thin skin of resin. This will require some very careful

sanding and undoubtedly, some filling will be needed as well. Fixing the

gouge can be done with repeated doses of gap filling superglue, followed

by accelerator and a final sanding (being careful not to get too carried

away!).

The final shot (image 4) shows the main wheel well. In here are a number of air bubbles and these will, for the most part, not be an easy fix. This is especially true of those that are in the wheel well roof detail section. These were probably made from Evergreen strip styrene on the master. In order to repair them, I'm going to have to assume that removing the bad sections and replacing them with more strip styrene is the only answer if you want a contest quality kit.

The only other part in the kit are the transparencies. These are vacuformed and the frame lines are quite indistinct. It will be a bit of a problem to mask them with anything other than clear tape. Again, only one set is provided. I feel that if such indistinct canopies are to be provided, then a second set should be included.

As

with other Anigrand kits, the instructions are on a single sheet of

paper. One side has a short history, photo and exploded construction

drawing. The other side is a very nice three view and painting guide. The

guide states mid grey for the cockpit and wheel wells with an overall

white color scheme. For the cockpit I'd go with Dark Gull Grey as that is

pretty well what most cockpits of the time were painted. I might also go

with white for the gear and gear bays, though it wouldn't be out of

character to paint the wells in ADC Grey. In fact, I'll be scrounging

through the F-106 decals for this one when it comes time to build it! Kit

decals are well printed and provide just basic insignia and markings.

As

with other Anigrand kits, the instructions are on a single sheet of

paper. One side has a short history, photo and exploded construction

drawing. The other side is a very nice three view and painting guide. The

guide states mid grey for the cockpit and wheel wells with an overall

white color scheme. For the cockpit I'd go with Dark Gull Grey as that is

pretty well what most cockpits of the time were painted. I might also go

with white for the gear and gear bays, though it wouldn't be out of

character to paint the wells in ADC Grey. In fact, I'll be scrounging

through the F-106 decals for this one when it comes time to build it! Kit

decals are well printed and provide just basic insignia and markings.

|

CONCLUSIONS |

Ok, I've now whined about the glitches on the kit. Does that mean I don't like it. Heck no. I love aircraft like this. When it comes to short run kits of any type, it is the subject that sells it. None of the problems are insurmountable and any modelers who are at the stage of being able to tackle a kit like this will not have trouble fixing the glitches.

From just a personal standpoint, I enjoy a kit that offers a bit of a challenge when it comes to construction. I also feel it only honest to point them out during a preview. Overcoming these problems allows me to think and come up with solutions. Now I do realize that there are folks out there who want everything perfect. That is fine and there are lots of kits out there that can almost be built in one's sleep. Nothing wrong with that and I like to build kits like that myself from time to time. But the purpose of a hobby is to do things that one likes. I like kits like this and that is why I keep building them. As much as I fuss about Anigrand's kits, I'm still pleased that they have taken the time to produce kits of subjects like this. From what I understand, a lot of other people believe the same thing as DMC has trouble keeping up with demand. I can see why.

Many thanks to DMC Models for the review kit.

UPDATE: Nostalgic Plastic is now the US Importer for Anigrand. Please contact them for more information.

If you would like your product reviewed fairly and quickly by a site that has nearly 250,000 visitors a month, please contact me or see other details in the Note to Contributors.